Are all sewing machine bobbins the same? The answer to this question is, unfortunately, no. Bobbins can come in different sizes, materials, and shapes. The type of bobbin used for your sewing machine depends on several factors, such as the make and model of the machine, the project you’re sewing, and the type of thread used. It is important to know the right type of bobbin for your machine so that your project can turn out successfully.

To choose the right bobbin, you need to consider the machine’s compatibility. For example, if you have an old Singer sewing machine, you will want to make sure the bobbin is made for that particular Singer model. There is usually a number listed on the bobbin’s pack that will tell you if it is compatible with your machine. Most machines come with a few extra bobbins, so you should always check to see what type of bobbins they specify for your machine.

The size of the bobbin also plays a role in determining the type of bobbin you need. The sizes for most machines range from 7/16″ to 1-1/4″ and the design of the bobbin varies slightly by machine. If you need to buy bobbins for your machine, you will need to make sure you get the same size as the ones that came with the machine, otherwise they might not work. It is also important to check the size of the spool thread you’re using because some of them are specifically designed for use with certain sizes of bobbins.

The material of the bobbin is also a factor. They can be made of metal or plastic, with plastic being the most popular. Metal bobbins offer the advantage of being stronger and can last longer than plastic, but they can be more difficult to use. On the other hand, plastic bobbins are cheaper, lighter, and are less likely to jam during use. For heavier projects and materials like denim, metal bobbins might be better since they can handle more pressure. Plastic bobbins are better for lightweight and lacy materials.

The shape of the bobbin usually depends on the type of machine you have. For example, oscillating shuttle machines usually require a cylindrical bobbin while rotary hook and full rotary machines require a round bobbin. These requirements are usually stated somewhere in the manual or on the machine itself, but if you’re ever in doubt, it’s best to consult a professional or the manufacturer.

When it comes to finding the right bobbin for a specific machine, it is important to take all of these factors into consideration. While it is tempting to just buy whatever bobbins you can find without too much thought, taking the time to do a bit of research and make sure you have the right ones for your machine can save a lot of headache in the long run.

Bobbin Material

Metal and plastic bobbins have different advantages and disadvantages. Metal bobbins last longer and are generally stronger than plastic. They are more expensive and often more difficult to use with some machines. Plastic bobbins are cheaper, lighter, and less likely to jam during use. For heavier projects, metal bobbins might work better since they can handle more stress while plastic bobbins work better with lightweight projects.

When it comes to bobbins, there are a few things to consider. No two machines are the same, so you always want to make sure that the bobbin you purchase is the same size and shape as the one that came with your machine. Check the manufacturer’s instructions to be sure that the bobbin you buy is compatible. Additionally, the material of the bobbin should also be taken into consideration. In general, metal bobbins last longer and can handle more stress but plastic bobbins are less likely to jam and are often lighter and cheaper.

Bobbin Compatibility

Choosing the right bobbin for a particular machine depends on several factors. It is important to know the compatibility of your machine with a certain type of bobbin. Each machine usually comes with a few extra bobbins, so you should always check to see what type of bobbins they specify for your machine. The size of the bobbin also matters and they usually range from 7/16″ to 1-1/4″. Additionally, the design of the bobbin will also be slightly different depending on the type of machine. Check the manufacturer’s instructions or consult a professional from the store you buy from.

The type of thread you’re using is an important factor in bobbin compatibility. Make sure to check the thread size to see what type of bobbins are compatible with it. Similarly, bigger thread will require a larger bobbin and lighter thread will require a smaller bobbin. Taking the time to make sure you have the right bobbin for your machine can make all the difference when it comes to your sewing projects.

Bobbin Care

It is important to take good care of the bobbins you use to ensure they last longer. After each use, be sure to empty and clean your bobbins. If you’re using plastic bobbins, you can use a damp cloth or q-tips to make sure they are free of any lint or dust. The same goes for metal bobbins, but you can also use a bit of metal polish if you want them to last a bit longer. Additionally, it’s also important to store your bobbins properly. If you’re not using them, you should keep them in their original containers, away from dust and moisture.

It’s also important to check the bobbin for any damages. Make sure that the bobbin case is closed securely and the thread is in the grooves of the bobbin. If the bobbin is cracked, discolored, deformed, or otherwise damaged, it should not be used. This applies to both plastic and metal bobbins. Pay close attention when using the bobbin and make sure that you follow the instructions and use the machine correctly.

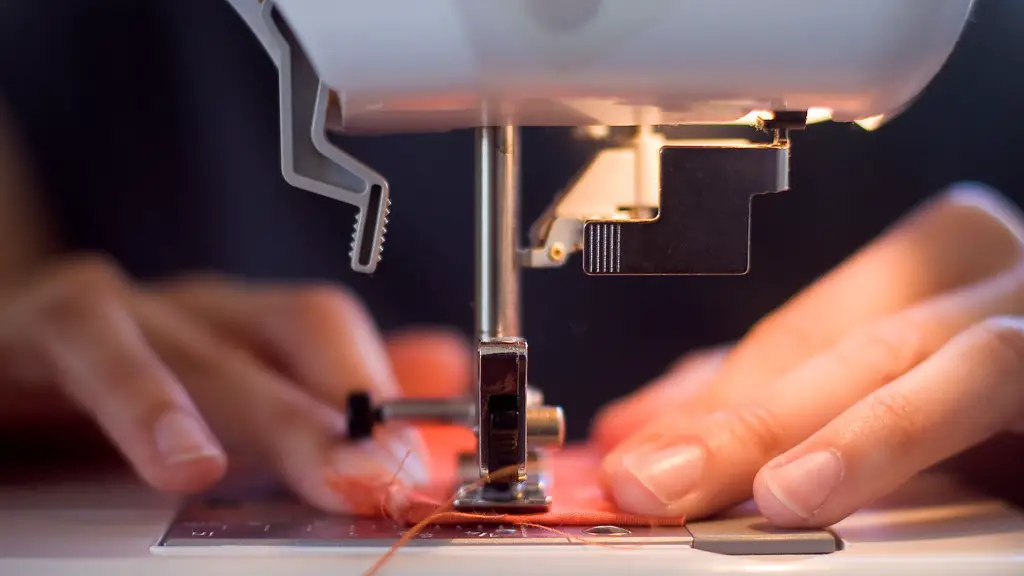

Threading the Bobbin

Threading the bobbin correctly is one of the most important steps in sewing. Depending on your machine, threading the bobbin will be slightly different. Most machines have diagrams in the manual to help guide you through the process. Be sure to pay close attention to the diagrams to avoid confusion. Generally, the bobbin should be placed below the needle and the machine should be running while you are threading the bobbin. Be sure to only use the specified bobbin and thread for each machine.

Once you finish threading the bobbin, make sure that the bobbin tension is adjusted correctly to prevent the thread from becoming tangled or loose. The manufacturer’s instructions will tell you how to do this properly. The bobbin tension should be tight but not too tight. Always double check that the tension is correct before you begin sewing, as incorrect tension can cause problems like poor stitch quality, excess thread build-up, and inaccurate seam widths.

Bobbin Troubleshooting

Bobbins can cause a few sewing machine problems. Improper bobbin tension can cause threading problems and can also cause the machine to jam. If the bobbin case is not in the right position, it can also cause problems. Additionally, incorrect bobbin sizes and thread type can also cause the machine to jam or not work properly. Check the manual or your machine’s manufacturer’s website to make sure you are using the correct kind of bobbin.

If you are having issues with your bobbin, the first thing you should do is clean it. You can use a damp cloth or q-tips to clean the bobbin case, and make sure there are no dust or lint inside. Be sure to also check the tension. If the thread is too tight or too loose, it can cause problems with the bobbin. If cleaning and changing the tension doesn’t help, try using another bobbin and make sure that it is the same size and type as the original one.

Another problem could be with the needle. Make sure that the needle is inserted properly and that it is not bent or burred. Make sure it is the right size and type for the fabric you are using. It is also important to make sure that the machine is threaded properly. If your machine is threaded incorrectly, this will affect the stitch quality and the bobbin will not work properly.