Maintaining your sewing machine is an essential part of being a successful sewer. Sewing machines that are not properly cared for can cause frustration and lead to defective projects. The right oil applied to the correct places on your Kenmore sewing machine is one of the simplest and most important maintenance tasks you should do to keep your machine running smoothly.

Kenmore sewing machines are an iconic brand with a solid history and many of the same principles found in other popular machine models. Sewers should choose an appropriate oil for the machine, such as sewing machine oil, mineral oil, or lightweight machine oil. Avoid anything labeled as “sewing lubricant” or “multi-purpose oil,” as these can buildup and damage delicate parts of the machine.

Most basic Kenmore sewing machines require only one or two drops of oil per month when in regular use and should be oiled every six months when in storage. To begin, sewers should remove the upper portion of the machine and locate any screws or hinges that need to be loosened or removed to get inside. From there, locate moving parts and oil them, such as the needle bar, the needle bar connection, the face plate, the bobbin case, and the presser foot.

In addition to oiling the moving parts of the machine, it is equally important to oil the non-moving parts. Examples of these parts include the tension disks, the handwheel, the bobbin tension knob, and the bobbin control system. All of these should be oiled lightly, with no more than a drop per month, to ensure that the machine operates correctly and without fault.

The timing of the sewing machine is also important to consider when oiling. Timed machines, such as those found in the Vintage Kenmore models, have teeth on the needle bar, as well as gears and other internal components. The timing should be checked and adjusted if necessary following every oiling. Moving and un-moving parts should be checked for cracks or wear and tear, such as broken or chipped teeth or bent shafts, in order to identify and repair any issues before they become larger problems.

Finally, the key to keeping your Kenmore sewing machine running smoothly is to remember the basics: oiling regularly, always using the right type of oil for the machine, and checking for any faults. Following these easy steps, along with the occasional cleaning and timing check, can help you to create beautiful garments and projects with ease.

Cleaning the Sewing Machine

Cleaning your sewing machine periodically can help to maintain its performance and longevity. The cleaning process involves more than just wiping down the outside of the machine; it also involves removing dust and lint from the internal components of the machine. Sewers should first use a brush to dust off the outside of the machine and inspect it for any damage or loose parts.

To clean the inside of the machine, sewers should use a damp cloth or brush to clean any areas with visible dust or dirt build-up. Additionally, a compressed air canister can be used to dislodge any stubborn lint or dirt. Sewers should pay particular attention to the feed dogs, as these can easily become clogged with lint or thread. Special attention should also be paid to the bobbin case, as it can often be overlooked in cleaning.

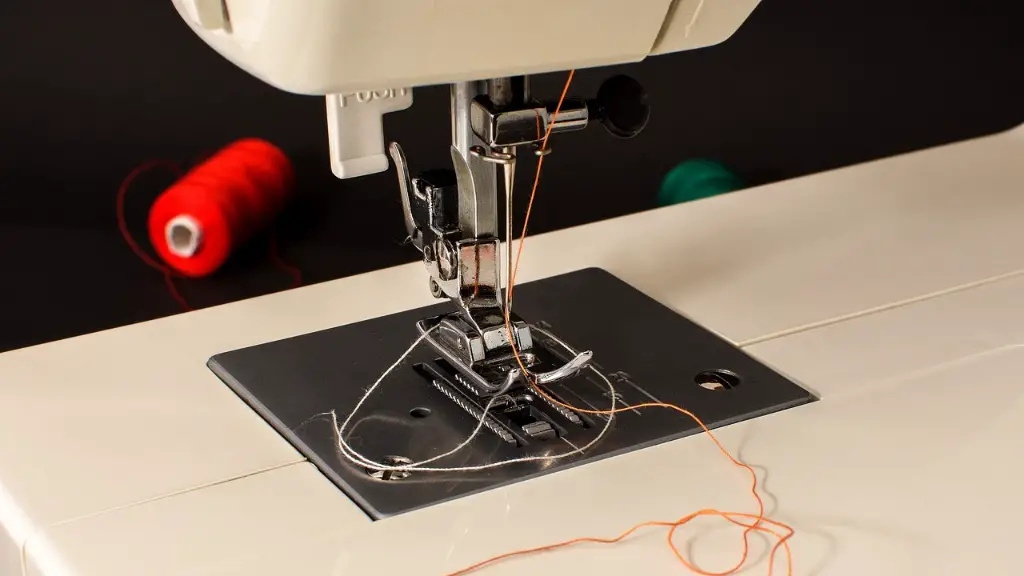

Sewers should also check that the needle is in good condition and is correctly inserted into the machine. It is important to note that needles should be replaced on a regular basis; a worn needle can cause excessive thread breakage and stitch skipped. Once the needle is checked and replaced as necessary, sewers should check the tension settings, thread guides, and other small parts for any damage.

Once all of the dust and dirt are removed from the sewing machine, sewers can then oil any moving parts as detailed earlier and reassemble the machine. The machine should now be running smoothly and ready for use.

Troubleshooting Common Problems

The most common issue sewers experience with the Kenmore Sewing Machine comes from wiping out the bobbin case too often. Over-cleaning the bobbin case can cause the timing to become unbalanced and the machine to misalign. This problem can lead to thread breakage, skipped stitches, needle breakage, and uneven tension.

Another common problem is thread looping. This happens when the thread has become tangled around the bobbin, causing the needle to become damaged or the fabric to be perforated. Using the wrong needle, such as a too-large needle for the thread material, can cause thread looping. In this case, the needle needs to be changed for the appropriate size and the thread guides need to be checked for any catching or pulling.

Kenmore sewing machines can also occasionally experience skipping stitches or fabric puckers from improper thread tension. Puckers and skipped stitches occur when the tension on the upper thread is either too loose or too tight. Thus, sewers should regularly check the tension and adjust it according to the fabric they are using and the stitch they are creating.

To help prevent these problems, sewers should remember to unplug the sewing machine and oil it regularly. Additionally, always use the right type of thread and needle for the material and project, respectively. Lastly, remember to routinely check the timing of the machine as this can lead to a smoother operation and project completion.

Storing the Sewing Machine

Storing the Kenmore Sewing Machine properly is critical if the machine is going to last for years to come. As with any other type of machinery, the machine needs to be taken care of, even when it is not in use. It’s important to remember to oil the machine before storing, to prevent rust and wear and tear. Additionally, the machine should be covered with a dust cover and stored in an area with low humidity and minimal dust exposure.

The power cord should also be disconnected and stored separately from the machine. If the sewing machine is to be stored in an area with children or pets, it is important to make sure that the machine is locked up and out of reach. Sewers should also cover the machine with a cloth or cover and be sure to provide adequate air circulation to the machine.

Sewing machines should also be protected from extreme temperatures. Sewers should be careful not to store the machine in places that can become too hot, such as the car in summers, or too cold, such as outdoors in winter. Additionally, any stored thread and needles should be kept in a sealed box away from the machine and stored in a temperature-controlled environment.

By following the tips above, sewers can ensure that their Kenmore Sewing Machine is properly cared for and stored, even when not in use. Adequate maintenance and care will help to ensure that the machine runs smoothly and has a longer life.

Caring for the Sewing Machine

Caring for the Kenmore Sewing Machine is essential in order to keep it in tip top condition. The most important task is to oil the machine regularly; the frequency of this will depend on the individual machine, but approximately once every three months is recommended for most machines. Sewers should also be sure to use the appropriate type of oil for their machine, such as sewing machine oil, mineral oil, or lightweight machine oil.

Additionally, it is important to always use the correct type of stitch for the project. Sewers should also evaluate their own technique and form when stitching, as this can greatly impact the machine’s performance. Keeping the machine clean and dust-free is also important- a soft cloth and some mild detergent can be used for this task.

Finally, sewers should remember to always use the right type of needle, tension settings, and thread for the fabric being used and the type of stitch being created. Many times, simply changing the needle size or thread type can help when the machine performs erratically.

By following these basic tips, sewers can ensure that their Kenmore sewing machine is properly cared for and running smoothly. Regular maintenance and the right type of oil are key in preserving your machine’s performance and efficiency.

Conclusion

Caring for your Kenmore sewing machine requires some simple steps that, when followed, will help you get the most out of your machine. The key is to remember to oil the machine regularly and to use the type and amount of oil specified for your machine model. Additionally, regular maintenance and dust control is important to keep the machine running smoothly and efficiently. Finally, always use the right type of needle, thread, tension settings, and stitches for each project.