There are many benefits to using walking feet when sewing heavy fabrics together. Walking feet help to evenly feed the fabric through the machine, which can prevent fabric from bunching up or becoming uneven. Additionally, walking feet can help to prevent fabric from stretching or becoming distorted when sewing thick fabrics together.

There is no definitive answer to this question. Some sewers prefer walking feet for sewing heavy fabrics together because they feel that it gives them more control over the fabric. Other sewers prefer to use a regular presser foot because they find it easier to sew a straight seam with this type of foot. Ultimately, it is up to the sewer to decide which type of foot works best for them when sewing heavy fabrics together.

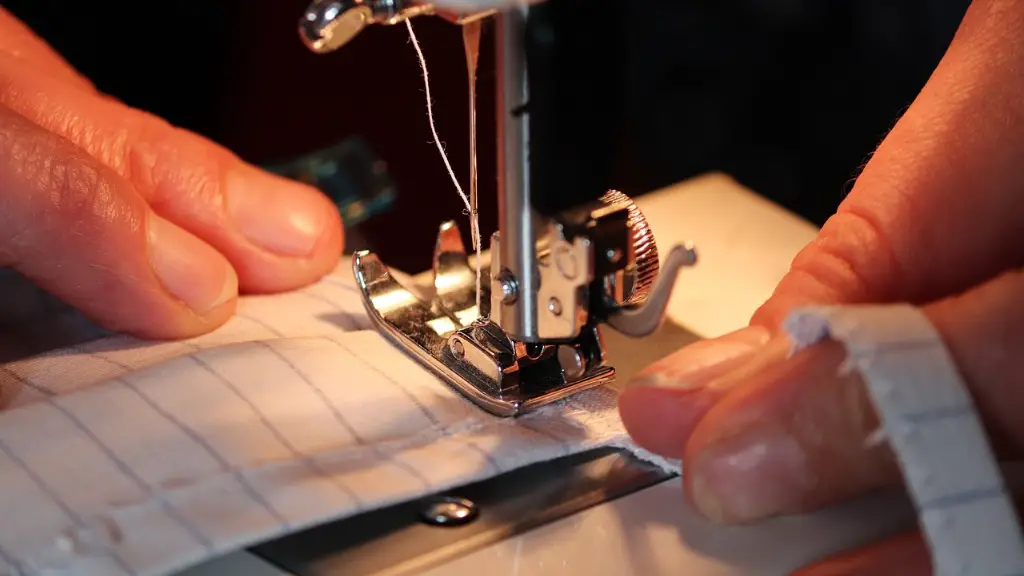

What sewing foot should I use for thick fabric?

When sewing thick fabrics, it is important to check for special feet that may be needed in order to sew the fabric correctly. A walking foot that allows the top and bottom fabrics to move together is a great help, as is a roller foot that helps to feed the fabric under the foot. Teflon feet also have a non-stick coated underside that can help all kinds of fabrics glide through the machine.

The walking foot is a special attachment for a sewing machine that helps to keep fabric from slipping as it feeds through the machine. This is especially helpful for lighter weight knit fabrics, to prevent stretching, and for perfect pattern matching on plaid fabrics. It is also helpful for quilting, to keep the layers of a quilt from shifting as they are quilted together.

Can I use walking foot for all sewing

A walking foot is a type of sewing machine foot that helps to prevent fabric from shifting or puckering. This is especially useful for quilting or sewing garments, as it helps to keep the fabric from stretching or bunching up.

The walking foot is a great tool for quilting, especially when you need to keep fabric and batting layers together. It’s also great for machine quilting straight lines and large, gently curved lines.

Is a walking foot good for thick fabric?

If you’re working with a heavy fabric, you’ll want to make sure you have a walking foot for your sewing machine. This type of foot will help feed the fabric through the machine evenly and prevent it from bunching up. You may also want to use a thicker seam allowance when working with heavy fabrics to account for the extra bulk.

A walking foot is a type of presser foot that helps to sew thick layers of fabric evenly. The presser foot on top of the fabric moves along with the feed dogs underneath, which helps to prevent puckering or shifting of the fabric layers.

What are the most useful sewing feet?

The all-purpose presser foot is the most useful sewing machine foot because it can straight stitch, zig-zag, and sew many decorative stitches. In fact, you can probably use this foot for most of your sewing tasks. This versatility makes it an essential foot for any sewing machine.

If you don’t want to use a walking foot, your best alternative is a darning or hopping foot. With this foot, you have to drop your sewing machine’s feed dogs. You’re in charge of moving the quilt sandwich through your sewing machine and creating the stitch length.

What’s the difference between a walking foot and a quilting foot

There are a few key differences between a quilting foot and a walking foot. First, a quilting foot will enable the quilter to feed the fabric through the machine in different directions. This is because the quilting foot has a guide that helps keep the fabric moving in a straight line. In contrast, a walking foot is only useful for straight line sewing. This is because the walking foot does not have a guide, and instead relies on the quilter to keep the fabric moving in a straight line. Second, a quilting foot is used for free motion embroidered pieces and free motion quilting. This is because the quilting foot has a special foot that helps to prevent the fabric from shifting. In contrast, a walking foot is not used for free motion embroidered pieces or free motion quilting.

15mm is the perfect stitch length for walking foot quilting! It’s my favorite setting to use because it’s the perfect balance between speed and accuracy. Plus, it’s the setting I use for piecing too, so it’s become a routine to sit down at my machine and immediately adjust the stitch length down to this setting.

Can you sew curves with a walking foot?

Hi Matt,

Thanks for the tip! When quilting with a walking foot, you can indeed go beyond straight lines – you can also do curved or even free-motion quilting! It’s all about finding the right foot for the job and getting a feel for how your machine handles. With a little practice, you’ll be able to quilt any design you can dream up!

I’ve found that using a Walking Foot to sew fleece is incredibly helpful because I don’t have to pin as much (or sometimes, not pin at all). Fleece has a tendency to shift around, so having an extra set of feed dogs really helps.

Can you sew a zipper with a walking foot

Sewing clips are a great way to hold fabric in place while you sew. I like to use them when I’m sewing a straight seam, because it keeps the fabric from shifting and makes the seam nice and straight. You can use a zipper foot or a regular foot, but I find that a regular foot works just fine.

If you are experiencing pain or weakness on one side of your body that is making it difficult to walk or maintain balance, using a cane may be helpful. If you have poor balance or feel unsteady on your feet, a walker may give you more support.

What is the difference between a walking foot and an open toe walking foot?

The only difference between these two versions of the same quilting foot is a small piece of metal between the two ‘toes’ of the foot. With the ‘open toe’ version, there is no metal piece and you have a clear line of sight to where the needle pierces through your quilt sandwich. This can be helpful when quilting around intricate designs or working with small pieces.

The presser foot lever can be raised to two different positions. The first position is for when the fabric does not fit under the presser foot, for example, when sewing together thick fabrics. In this position, the fabric can be placed under the presser foot. The second position is for when the fabric is too thick to fit under the presser foot. In this position, the fabric can be placed under the presser foot and the presser foot lever can be used to raise the presser foot.

Conclusion

There is no definitive answer to this question since it depends on the specific fabric and project. Some sewers prefer walking feet for sewing heavyweight fabrics together because they feel it gives more even pressure and prevents fabric from shifting. Others find that a standard presser foot works just as well. Ultimately, it is a matter of personal preference.

There is no right or wrong answer when it comes to walking feet and heavy fabrics. It is simply a matter of preference. Some sewers find that walking feet help to evenly feed heavy fabrics through the machine, while others find that they can sew just as well without a walking foot. Ultimately, it is up to the sewer to decide what works best for them.