Understanding Thick Thread

The idea of using thick thread in a sewing machine is quite common amongst hobbyists, tailors, and home sewers alike. Thick thread can be used to create unique and elaborate stitches, and it can be used to embroider and quilt. There are different types of thick thread to choose from, and it’s important to understand the different thicknesses and how they affect the stitching machine.

Thick thread is usually made from a variety of materials such as cotton, rayon, and polyester. The thread is measured by the Tex system, which is the weight in grams per kilometer of thread. A higher Tex rating means a thicker thread; for example, a 40 Tex thread is much thicker than a 20 Tex thread.

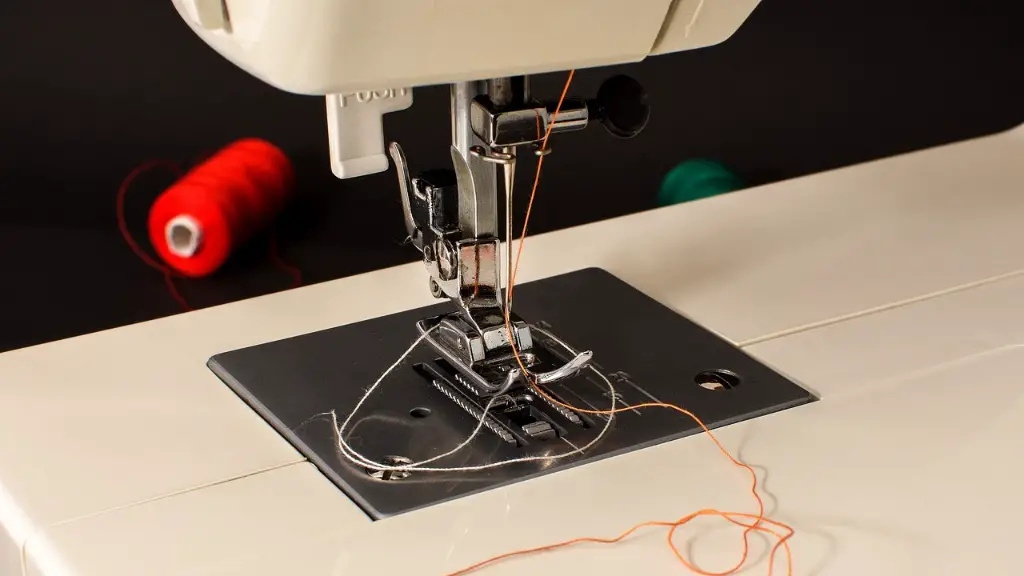

When using thick thread in a sewing machine, it’s important to make sure the thread doesn’t exceed what the machine is designed for. Thread that is too thick can cause damage to the machine, and it can cause the stitches to be too tight or too loose. It’s also important to make sure the machine is properly threaded before attempting to sew with thick thread; if the thread is not correctly threaded, the thread can become tangled and result in poor stitching.

In order to use thick thread in a sewing machine, it’s important to have the right needle and settings. A larger needle should be used; the size of the needle should correspond to the weight of the thread. For example, a 40 Tex thread should be used with a size 90/14 needle. Many modern machines also have an auto-tension feature for thicker threads, which can help ensure the stitches are even and the thread doesn’t become too tight or too loose.

When sewing with thick thread, it’s important to make sure the machine is properly oiled and maintained. Also, it’s recommended to use a variety of stitches when sewing with thick thread; this keeps the stitches even and lessens the burden on the machine. Finally, it’s important to always use a high-quality thread with the sewing machine; this ensures the thread does not become tangled or damaged and can help ensure the stitches are even.

Effects of Thick Threads on Fabric

When using thick threads on fabrics, it’s important to consider the type of fabric and how it will react to the thread. Different materials handle thick thread differently; for example, fabrics such as quilting cotton or muslin can handle thick thread without issue, but finer fabrics such as silk or linen can be damaged by thick threads. It is important to test out the thread on scrap fabric before using it on a project.

In addition to the type of fabric, it’s important to consider the type of stitch being used when sewing with thick thread. Depending on the type of thick thread used, some stitches may work better than others. For example, a simple straight stitch may work better with a thicker thread than a decorative stitch, as the stitches created by a thicker thread can often cover up the decorative stitching.

Finally, it’s important to consider the tension settings when sewing with thick thread. Too much tension can cause the fabric to pucker or have uneven stitches, while too little tension can cause the thread to bunch up and cause the stitches to be irregular. It’s important to adjust the tension settings accordingly; this can involve playing around with the settings or consulting the sewing machine’s manual for the correct settings for different types of stitch and thread.

Caring for Threads

When using thick threads, it’s important to take care of the threads to ensure they last and remain in good condition. It’s important to store thick threads in a cool, dark place to ensure the threads do not become damaged by exposure to light, heat, and moisture. Additionally, it’s important to make sure the threads are wound properly before storing them; this helps ensure the threads will not become untangled and can be used properly when needed.

In addition to proper storage, it’s also important to make sure the threads are cleaned regularly. This helps remove dirt and debris, which can cause the threads to become damaged and decrease the machine’s efficiency. It’s also important to clean the threads before and after each use to help ensure the threads remain in good condition. A gentle brush or vacuum is usually enough to remove dirt and debris, and this should be done with all types of threads.

Finally, it’s important to use the correct needles when working with thicker threads. Needles should be changed as needed; this can range from every few stitches to every few projects depending on the type of thread and fabric being used. Using the wrong needle can cause the threads to become damaged or can cause the stitches to be uneven and sloppy, so it’s important to ensure the correct needles are used.

Regular Maintenance

When sewing with thick threads, it’s important to make sure the sewing machine is regularly maintained. It’s important to have the machine cleaned and lubricated regularly, as this helps ensure the machine continues to run smoothly. Additionally, it’s also important to periodically test the tension settings and adjust them as needed; this helps ensure the tension is not too tight or too loose and can affect the stitches created by the machine. Finally, it’s important to inspect the machine and make sure everything is in good condition, as this can prevent any issues from occurring while the machine is in use.

When working with thick thread, it’s also important to periodically inspect the needle and thread for any signs of wear or damage. Additionally, it’s also important to regularly inspect the bobbin for any signs of damage or wear; this helps ensure the threads don’t become tangled and the machine continues to run smoothly. Finally, it’s important to ensure the tension settings are not too tight or too loose; this can be done by periodically checking the tension settings and adjusting them if needed.

Choosing the Right Thread

When it comes to selecting thick threads, it’s important to choose the right thread for the project. Different threads have different weights and textures, so it’s important to consider these factors when selecting the right thread. Additionally, it’s important to consider the type of fabric and the type of stitch being used; for example, some fabrics are better suited for thicker threads than others, and some stitches may work better with thicker threads than others.

In addition to the type of thread being used, it’s also important to consider the color of the thread. Different colors of the thread can add a unique look to a project; for example, a bright-colored thread may add a unique touch to a quilt or embroidery project. Additionally, some threads may blend better than others; this can be an important factor when attempting to blend the thread with the fabric.

Finally, it’s important to consider the cost of the thread. Thick threads can be more expensive than thin threads, so it’s important to consider the cost when selecting the right thread. Additionally, it’s important to consider the quality of the thread; higher-quality threads are often more expensive, but they can also last longer and produce better results.

Conclusion and Results

Using thick thread in a sewing machine can add a unique and elaborate look to any project. It’s important to make sure the correct needle is used and the correct tension settings are in place, as this ensures the stitches created by the machine are even and not too tight or too loose. Additionally, it’s important to take care of the threads to ensure they last and remain in good condition; this includes regularly cleaning and lubricating the threads, storing the threads correctly, and inspecting the needles and threads for any signs of wear or damage.

Choosing the right thread is also important; this includes considering the type of thread, the type of fabric, the color of the thread, and the cost of the thread. Additionally, it’s important to make sure the sewing machine is regularly maintained and tested; this helps ensure the machine continues to run smoothly and the stitches remain even and consistent. It’s also important to inspect the thread and needle for any signs of wear or damage; this helps ensure the threads don’t become tangled or damaged and the machine continues to produce the desired results.