General Overview

Maintaining a sewing machine can be a daunting task, especially if you’re a beginner. Oiling your Kenmore sewing machine is an easy and essential way to ensure your machine’s continued longevity and performance. This is because oil helps to preserve the condition of the inner mechanisms of your machine, by providing lubrication and preventing corrosion by moisture. Moreover, the process of oiling a sewing machine only takes a few minutes and can help prevent an expensive repair in the future.

Preparation

Before you start oiling your Kenmore sewing machine, make sure you have an oiling solution and a couple of small brushes. You can usually find these items in the same store you bought your sewing machine from and they serve as essential tools for the oiling process. Additionally, it’s best to make sure the bed of your sewing machine is unthreaded and all needles are removed to prevent any potential accidents.

Oiling Process

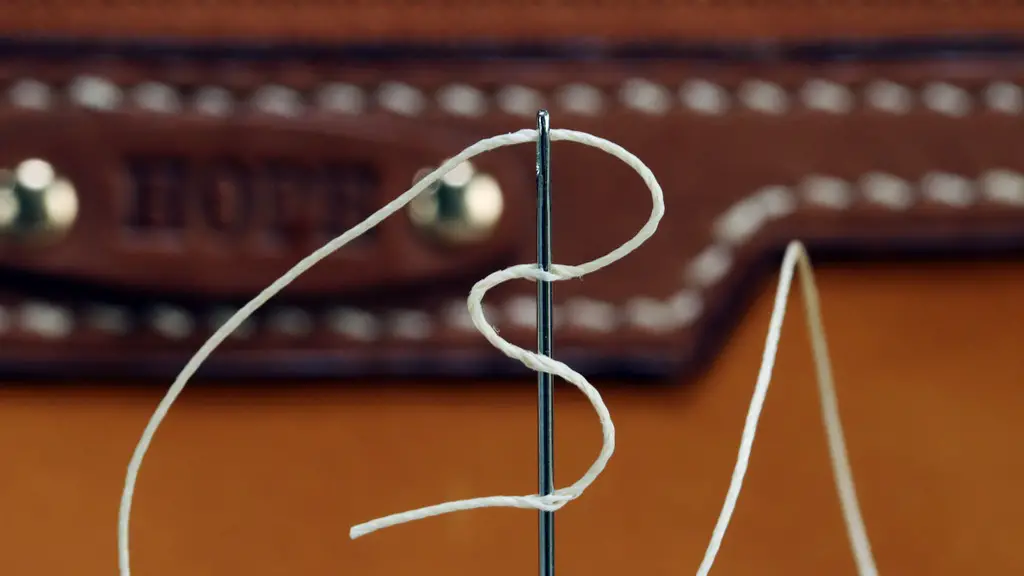

Now it’s time to actually oil your sewing machine. To start, clean the surface of your machine so it is free of any dust or lint. You can use a damp cloth to do this. Then, apply a few drops of oil to all the metal moving parts on the surface of your machine, or any other areas that have metal-on-metal contact. Make sure you avoid using too much oil, as it can potentially cause damage.

Once you have applied oil over all the metal moving parts, it’s time to turn your attention to the inner components of your machine. To do this, you need to remove your bobbin case and cover plates, if you have them. It’s important to refer to your machine’s manual to double-check the type of oil you’ll need for this part of the process.

Once you have the correct oil, use your brush to evenly spread it throughout all the moving parts of your machine’s inner components. When done, reassemble all the components of your machine and you’re done!

Troubleshooting Tips

If you’re having trouble finding oil or the instruction manual, two helpful tips can be replacing sewing machine parts and finding universal oil. If you’re having trouble locating the exact parts for your machine, many stores sell products specifically designed to accommodate different models and makes of sewing machines; universal oil is a type of lubricating oil that is suitable for any machine.

Additional Maintenance

Oiling your sewing machine is only one way of maintaining your machine’s condition. Other activities include: checking your tension settings from time to time, eating lint (especially from the bobbin case), cleaning your machine regularly (using a brush or vacuum) and checking your needle often. All these activities help guarantee that your machine is functioning properly, and their impact is far greater than just oiling it.

The Final Word

Maintaining your Kenmore sew machine should be an ongoing practice. As mentioned, oiling is essential for preserving your machine, but it’s not the only task to be considered. Regularly ensuring the condition of your machine helps to ensure its longevity and performance. This also prevents any extra costs from having to repair the machine due to poor maintenance. So roll up your sleeves, get your oil and brush, and dedicate some time to your machine’s maintenance!

Additional Factors to Consider

Environmental Impact

When purchasing oil for your sewing machine, it’s best to opt for eco-friendly options. It’s important to remember that most sewing machines are made with plastic components, and that oil products can seep into these parts during the oiling process. Eco-friendly oil options can help make sure these components don’t get tainted by harmful chemicals.

Keep a Maintenance Log

Creating a maintenance log is a great way of securing your sewing machine’s quality and performance. This document serves as a record of the exact steps you’ve taken to maintain your machine. You can include information such as when you last purchased a new needle, when were the last two serviced, when was the last time you oiled the machine, and any other details related to its maintenance.

Replace Parts as Necessary

Sometimes, damaged parts such as needles, presser feet and throws, among others, can affect the quality of your finished garments. To avoid this, the quickest solution is to replace the faulty parts as soon as possible. Doing so ensures your machine’s performance, eliminates any potential problems, and prevents you from having to pay high costs for faulty repairs in the future.

Professional Assistance

The best way to guarantee your sewing machine’s performance is by getting professional assistance as soon as possible. Having an expert mechanic or technician look into your machine is a great way of avoiding any potential damage and preventing expensive repairs.

When it comes to maintaining a Kenmore sewing machine, the key is to be proactive and perform regular maintenance. The process of oiling your machine is quick and effective, but it’s not the only activity that should be considered. Extra maintenance activities such as keeping a maintenance log, replacing parts as needed, and getting professional assistance are all essential to preserve the condition of your machine. After all, doing so will ensure your machine not only performs as expected, but looks as good as new for a long time!