Threading Basics

Threading a Singer Simple sewing machine is a relatively simple process, which involves winding the machine’s bobbin, loading it into the appropriate compartment and then drawing the thread through the tensioning mechanisms. Threading the needle is the final step and the thread is then ready for use.

Before threading, it is important to make sure that the thread spool holder is correctly secured to the sewing surface, so that the thread will feed correctly through the tensioning mechanism. Ideally, the presser foot should also be lifted to ensure that the bobbin and needle are correctly aligned.

When winding the bobbin, it is important to align the thread spool with the flat side of the sewing machine’s thread guide, so that the thread is pulled into the mechanism in the correct direction. A locking stitch is recommended, to ensure that the thread secures securely on the bobbin winding arm.

The bobbin needs to be securely loaded into the appropriate compartment, after being pulled up tightly to eliminate any slack. A click should be heard once it is in place, and then the paper clip or plunger found typically within the compartment can be slid into the opening to secure it.

The bobbin case then needs to be threaded, ensuring that the thread passes through the tensioning wheels to regulate the tension and minimise any potential tugs. It is important to regularly check the tension. Once the bobbin case is properly threaded, the needle will be ready to be threaded.

For threading the needle, the thread should be passed through the eyelet and pulled up towards the rear of the machine. The thread should then be passed through the two small slots found just above the needle and then back down. This will secure the thread in place and prevent any unravelling.

Once the thread is in place, it is important to make sure that the correct tension is set, as this is key to making sure that the thread is able to move freely and pulls correctly into the presser foot.

Maintenance and Care

For Singer simple sewing machines, it is recommended that the bobbin and bobbin case should be regularly cleaned to remove any accumulated dust or debris. This will help to ensure that it functions correctly and thread feeds efficiently, avoiding any potential machine jams.

The needle should also be checked for any potential wear or damage, especially before long projects. If any visible damage is present, it is recommended that it should be replaced immediately in order to avoid any unexpected issues with the threading. A curved needle is ideal, as it helps to ensure that the thread pulls effectively and securely.

Along with needing these regular and regular checks, it is important to lubricate the machine in order to ensure that it operates and threads correctly. The bobbin, hook and thread guides all need to be routinely lubricated and more details can usually be found in the machine’s manual.

Using Various Types of Threads

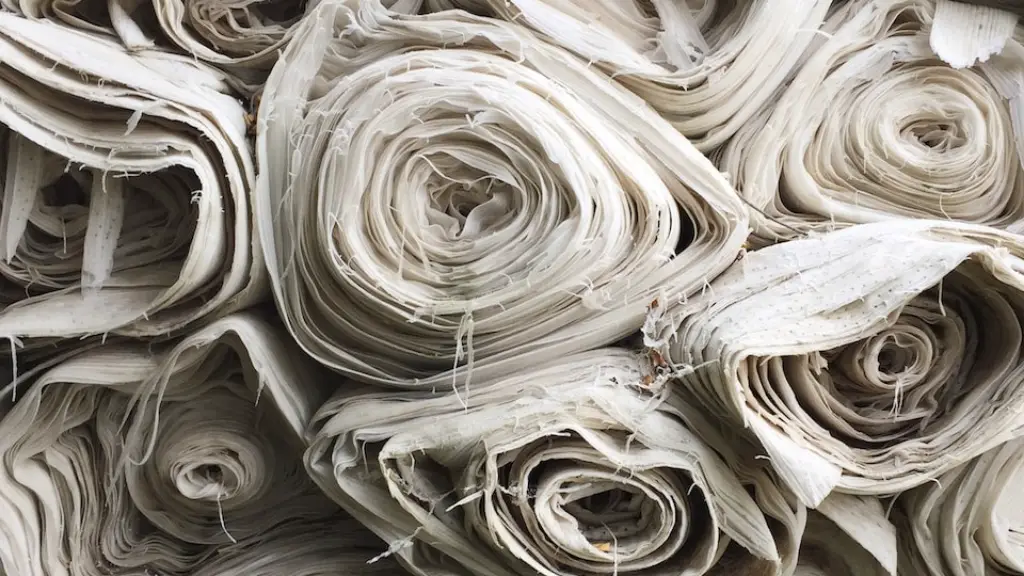

To ensure the best successful threading and running of the Singer simple sewing machine, it is important to use the correct type of thread. Generally, it is recommended to use nylon thread for heavy duty materials, such as canvas, and polyester thread for lighter fabrics, such as silk.

Cotton thread is generally versatile, suitable for most fabrics, but thinner fabrics such as batiste, chiffon and sheer fabrics do require a lightweight thread. It is also essential to use a stabiliser of some kind, such as interfacing, for heavier fabrics.

When purchasing thread, it is important to identify the thread’s size and weight, as these can affect the successful running of the machine. Threads usually come with a size number listed on the packaging, usually a higher number indicating a higher weight.

Threads need to be assessed to ensure they are suitable for the particular fabric, as some threads will be too fragile to be used with some fabrics. A thicker thread can be used to increase the strength, but too thick a thread can cause clumping and fraying. For example, lightweight silk should not be sewn with a heavy weight thread.

Loader Issues With Singer Machines

Loader issues can occasionally occur when using a Singer Simple sewing machine and this will have an effect on the threading of the machine. To avoid any loader complications, it is important to ensure that the feed dogs are correctly adjusted and are at the correct height.

The needles should also be tended to frequently, as an incorrectly inserted needle can cause several loading issues. If blades of the needle are misaligned, this can again can cause several problems.

It is recommended that any loaded materials should be aligned carefully, in order to eliminate any unnecessary complications. Additional issues arise when fabrics are loaded bi-directionally as this can obstruct smooth loading.

Incorrectly loaded materials can be responsible for threading jams. If jammed threading occurs multiple times, the machine might need to be looked at by a professional. Heavy fabrics should also be handled with care, as any sharp movements or pulls can cause the threads to unspool.

Stitches

It is advisable to practice some stitches with a Singer Simple machine, to become more familiar with its capabilities. By practicing with different fabrics, users can better determine the suitable stitches for their projects. The front of the machine usually has a dial indicating the type of stitch and users should consult the manual guide for more detailed instructions.

For heavier fabrics, a straight stitch is usually recommended, as this will make the finished product much stronger. However, a zig-zag stitch is often used for hems and a triple zig zag is usually used for overlocking and creating decorative, stretchy hems.

When creating buttonholes, it is important that the correct type of buttonhole stitch is chosen, based on the type of fabric being used. It is also important to ensure that the buttonhole is the correct size for the button that will be used. It is very important that tension is correctly adjusted when starting and finishing a buttonhole, as this will have an effect on the success of the project.

Troubleshooting

When threading a Singer Simple sewing machine, certain issues may arise. This can be due to incorrect threading, incorrect tension, tension being applied too quickly or the wrong type of thread being used.

It is important to make sure that the needle is correctly inserted and to check the bobbin winder to verify that the correct type of thread is being used. If the thread is too thin, it might not register with the tension wheels and if it is too thick, this can cause the bobbin case to be blocked.

When starting and finishing a project, it is important to slowly increase or decrease the tension, as this will provide better results. For further troubleshooting, the machine’s manual should be consulted for advice specific to the machine.

Safety Precautions

When handling a Singer Simple sewing machine, it is important to practice safety at all times. The machine should be kept away from youngsters and all attachments and accessories should be handled with care.

When using the machine, it is advisable to wear safety glasses, as well as keeping all accessories and tools away from the moving needles. The belt mechanism should also be kept away from hands and the machine should be unplugged when not in use.

When stocking the machine with thread, it is important to keep the thread spool holder adjusted correctly, as a loose holder could entangle the thread. In addition, threads should always be kept away from both eyes and moving parts.

Transporting Singer Machines

It is important to protect a Singer Simple sewing machine from any unexpected impacts or sudden movements when transporting it. Ideally, it should only ever be moved by two people and the machine should be kept in its original box.

It is recommended to wrap the machine up in bubble wrap to prevent any scratches or scrapes from occurring. The machine should be placed into the original box, so that it is protected from any impacts or vibration. It is also important to ensure that the machine is firmly secured within the box.

When transporting the machine between different locations, it is advised to fully secure it on the vehicle and keep it in a vertical position. Any bobbin and other accessories should also be removed and carefully packed away, as well as any fabrics that were being used.