Overview

Threading a Necchi sewing machine is not overly complicated, but it does require precision and thoroughness. If the thread is not properly loaded and tensioned, the stitches may not be accurate. Care should also be taken not to break the thread when threading the machine, as this may cause the machine to malfunction. Necchi sewing machines come with a comprehensive guide to help individuals thread the machine properly. This guide, along with the following tips, should help ensure that the machine is threaded properly and will sew properly.

Instructional Steps

The first step in threading a Necchi sewing machine is to cut off a length of thread from the spool. The thread should be at least twice the length of the spool, but no more than three times the length. This will prevent any tangling and knots in the thread. The thread should then be placed through the upper thread guide and lowered into the upper thread take-up lever before the spool and thread are gently placed onto the spindle.

The next step is to lead the thread through the thread eye in the needle. This is done by pulling out the needle threader from the side of the machine. The hook of the threader should be placed into the thread eye and the thread should be pulled under the hook. Pull the threader out, and it should be hooked in the two thread guides. Follow the arrows on the front of the machine to ensure that the thread is led through the right guide.

Once the thread is in the right guide, lower the needle down a few centimeters and lead the thread through the last guide, the lower thread guide. Now the lower thread take-up lever should be pulled forward until it is almost level with the upper part of the machine. Check the tension wheel at the back of the machine, this should be loosened at least two full turns for optimal results.

The next step is to lead the thread around the vertical post in the center of the machine and up through the left guide. Next, the thread should be pulled back out of the guide and threaded through the presser foot, then back down through the foot’s loop. Finally, wrap the thread around the wheel at the top of the loop and slide the wheel to the left side of the foot. This should secure the thread and the machine should now be ready for use.

Testing the Machine

Before actually sewing a project, it is important to ensure that the thread is properly tensioned and that the machine is running smoothly. To do this, make sure that the upper thread take-up lever is pulled all the way forward. Next, press the foot pedal to lower the needle and then begin to pull on the lower thread. If the upper thread is not being pulled through at the same rate, adjust the tension wheel until the thread is evenly tensioned.

Once the thread is properly tensioned, slowly press the foot pedal to make sure that the machine is running properly. If all the stitches are even, the machine is properly threaded and ready for use.

The Bobbin

In addition to threading the needle and upper thread, the bobbin must also be loaded properly. Start by locating the back sidebar and then open the hook cover at the top of the machine. Insert the bobbin into the bobbin case with the thread coming from the top of the spool and thread the bobbin through the tension area. Make sure to keep the thread taut and that the thread passes through the appropriate guides.

Once the thread is in the correct guides, insert the bobbin and pull the thread from the top. Now place the thread under the hook on the side of the machine, which runs on a wheel. Insert the bobbin into the hook/wheel and turn the wheel in the same direction as the arrow is pointing. Once the wheel has been completely turned, the bobbin should now be loaded and ready to use.

Troubleshooting Common Problems

When threading a Necchi sewing machine, it is important to pay attention to detail and not rush through the process. If the thread is not properly tensioned, or if the bobbin is incorrectly loaded, the machine may not run properly and the stitches may be off. If this does occur, double check the thread tension and the bobbin to make sure that everything is correct. Additionally, check for any knots or tangles in the thread.

If the thread is still not properly tensioned or the bobbin is still not loaded correctly, try changing the needle and/or thread to make sure that neither one is defective. If none of these solutions work, it is best to seek professional help from a sewing machine technician.

Replacing the Needle

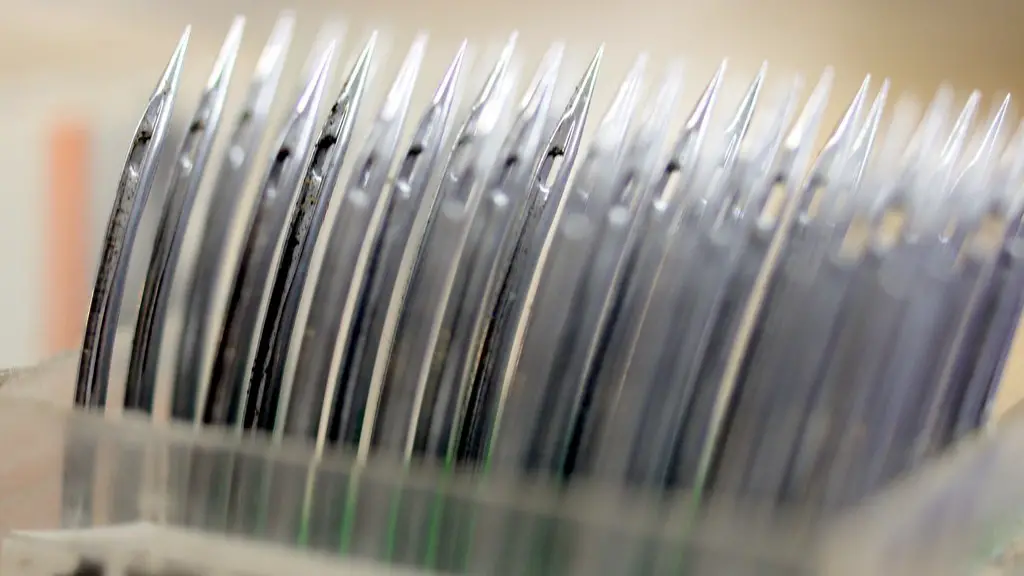

Replacing the needle is an important part of the overall operation of a Necchi sewing machine. To replace the needle, make sure that the machine is switched off and unplugged. Locate the needle clamp and loosen the clamp with a screwdriver. Carefully unscrew the needle and remove it from the machine.

To insert a new needle, place the base of the needle in the needle clamp so that the flat side of the needle is facing to the right. Make sure the needle is all the way down before tightening the clamp with a screwdriver. Switch the machine back on and press down the foot pedal to make sure the needle is working properly.

Caring for the Cartridge

The cartridge on a Necchi sewing machine must be properly cared for to ensure its longevity. After each use, the cartridge should cleaned with a soft cloth and oiled lightly in the direction of the arrow on its surface. This will prevent the cartridge from becoming worn and ensure that it is in good working order.

Additionally, Necchi sewing machine cartridges should not be left idle for long periods of time. This may cause the cartridge to malfunction, as the internal mechanisms may become stuck or corroded. To avoid this, make sure that the cartridge is kept in a cool, dry place when not in use.

Cleaning the Pressure Plate

Occasionally, the pressure plate on Necchi sewing machines should be cleaned. To do this, first use a screwdriver to loosen the plate and then remove the plate from the machine. Carefully wipe the plate clean with a softcloth and then inspect it for any signs of wear or tear. If any are found, the plate should be replaced immediately for optimal results.

Once the plate has been cleaned and inspected, it should be replaced and tightened with a screwdriver. Make sure to firmly tighten the plate, as a loose plate could damage the fabric or cause the machine to malfunction.

Maintaining the Feed Dogs

The feed dogs on a Necchi sewing machine are an incredibly important part of the overall operation. Occasionally, the feed dogs should be cleaned and oiled to ensure their optimal performance. To do this, switch the machine off and unplug it before using a small brush to remove any dust or debris from the feed dog.

Once the dust and debris have been removed, lightly oil the feed dog with a spray specifically designed for use with sewing machines. Make sure to keep the spray away from any open parts of the machine and avoid spraying over exposed fabric. Once the feed dog has been sprayed, switch the machine back on and press the foot pedal to make sure that the feed dog is working properly.