Thread Preparation

Before you can thread a sewing machine needle, it is important to prepare the thread correctly. Firstly, cut your thread with scissors that are sharp and clean. Make sure the ends are even and smooth, as any fraying or lumpy ended threads may cause tangling. Next, pick out thread in the same color as or a shade lighter than the fabric you’re sewing with. This will ensure a neat and even seam. For heavier fabrics such as denim, an extra-strong thread should be used. Cotton-wrapped polyester threads are a good choice for general purpose sewing and mending, or you can choose a heavier spool for machine quilting. Finally, check the length of your thread. It should be no longer than 1.5m (5ft) so it can fit easily on the spool.

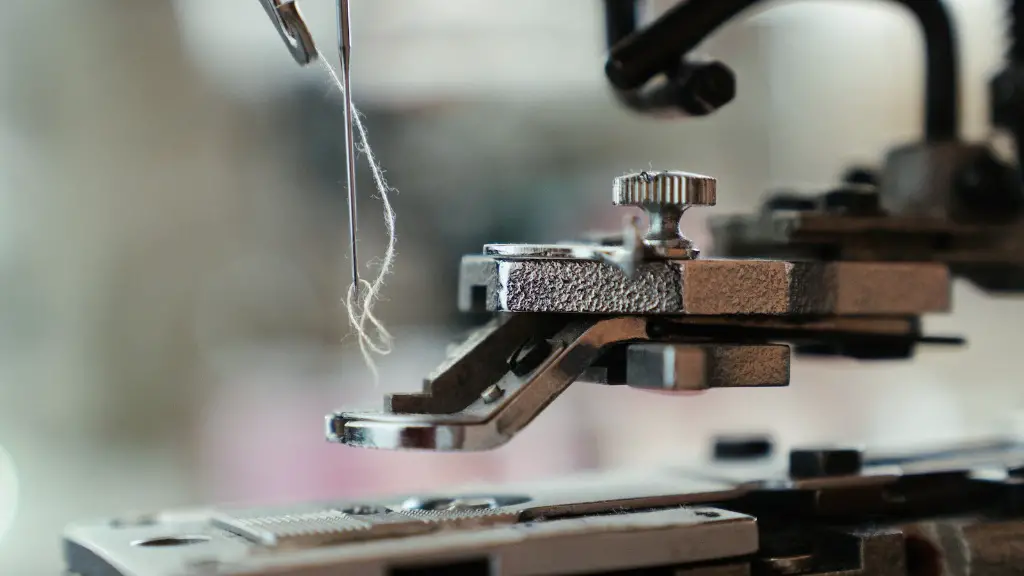

Finding & Attaching The Needle

Once you’ve prepared the thread, you can begin to thread the needle. First, find the right needle for your project. There are different types available, so it’s important to check the size and shape to ensure that it is suitable for the fabric and design. For detailed embroidery and appliqué, a sharp type should be used, while stretchy knits require a ballpoint needle. Next, lift the presser foot and remove the needle plate. Before inserting the needle, make sure the flat side of the needle faces back. Push it up from the underside, until it is all the way in. When the needle is fully inserted, tighten the screw that holds the needle in place. Now you’re ready to start threading!

Threading The Needle And Bobbin

Threading up the sewing machine needle is not as tricky as it may seem. Often, the upper and lower threads will travel in opposite directions. To thread the upper spool, first open the spool pin and place the end of the thread inside the hole. Pull the thread up and wrap it around the tension disc, then thread the needle from the front. Now you can attach the presser foot and lower the thread tension. To thread the bobbin, pull some thread out of the bobbin and hold it in the left hand. Guide the thread onto the bobbin winder, and then hold it to the left while winding. When the bobbin is full, cut the thread and push it into the bobbin case. Be sure to make sure the thread isn’t tangled, as this can cause issues when sewing.

Start Sewing

Once you’ve finished threading the needle and bobbin, you can begin to sew. Raise the presser foot and pull the thread from underneath it. Place the fabric between the presser foot and the needle. Pull the thread for several inches and put the needle down, then raise it back up. This will secure the thread to the fabric and create a tight, even seam. Lastly, adjust the tension on the thread. Check the manual of your machine, as there will usually be a recommended setting for different types of fabric. When the tension is set correctly, you should be able to pull the thread to the back of the work and create an even seam.

Maintaining Consistency

Adding a new spool of thread can be a hassle when sewing with a machine, as it often involves repeating the entire process of threading up. To make this process easier and keep sewing consistent, some machines come with an automatic needle threader feature. This is a device that wraps the thread on the needle with a simple push of a button. Whilst this is a time-saver and more favourable for the amateur and occasional sewer, it may still be beneficial if you are practicing and honing your sewing skills to manually thread your machine needle.

Using Quality Thread

The kind of thread you use does play a part in a project’s success. If you use low quality thread, your stitches may not look as neat and the thread may be more likely to break. With the right product and knowledge, you can have perfect, consistent stitches. Look for 100% polyester or cotton-wrapped polyester threads, and keep an eye on the tension and stitch length.

Other Tips & Advice

When sewing with a machine, never start with the foot pedal fully pressed down. This can cause the thread to tangle or break. To avoid this, gradually press the pedal until the thread is all the way through the fabric. If your fabric tends to get bunched up, the stitch length may be too long, or you may be using the wrong needle and thread. For example, a sharp needle will pierce finer fabrics such as silk and linen but may snag thicker materials like canvas and denim.

Cleaning The Machine

It is important to regularly clean your sewing machine in order to maintain smooth functioning and prevent major breakdowns. Check your manual for instructions specific to your machine, as there may be different procedures for different models. Generally waxing the needle is advisable, as this will make it smoother. Thread can sometimes get tangled in the feeder dogs, so releasing them and cleaning them is a good way to prevent thread-breaks during sewing. It is also worth dusting and wiping the frame with a dry cloth, as lint and dirt build-up can slow down or even stop the machine.

Troubleshooting & Maintenance

Occasionally, even the most skilled sewers will experience needle and thread issues. If the thread on your machine is continuously breaking, check if the tension is adjusted correctly. If the lower thread is too loose, the upper thread can bunch up and break. If both threads are breaking, the needle may need replacing or the spool pin may be stuck or blocked. If your needle is consistently skipping stitches, make sure the correct size and type of needle is used for the fabric and design. The needle may also be bent or blunt, so you should always choose good-quality needles and store them with the blunt ends down.

Protecting Against Tension & Robustness Issues

Incorrect tension and robustness can cause tangling, skipped stitches and an uneven seam. The best way to protect against this is to always use the right needle size and type and make sure it is correctly inserted into the machine before you start sewing. Use different thread weights for different fabrics and sew slowly. If necessary, use a smaller stitch width and length to ensure accuracy and reduce tension. Check the manual for its cleaning and maintenance instructions and always pay attention to the tension dials and knob.

Combating Fraying & Breakage

Fraying and breakage can be a problem when sewing with a machine. To avoid this, use a sharp pair of scissors to cut the thread. The thread should be no longer than 1.5m (5ft) and of the most suitable strength for the fabric you’re using. When threading the bobbin, hold the thread to the left and guide it onto the bobbin winder. Be sure to check the bobbin case for any snags or tangles, as this can cause problems with the stitch. When threading up, make sure the tension is set correctly and you adjust the thread length as needed.

Safe Storage & Organization

The most important thing to consider when threading a sewing machine needle is safe storage and organization. Always keep needles and thread in a safe place, out of reach of children and pets. It is also important to store them in a cool, dry environment. It is also wise to note the types and sizes of needles used for certain fabrics and designs, as over time you may forget what needle you used for what task. Lastly, make sure to always keep your machine in good working condition, as this will ensure a smooth and consistent sewing experience.