Sewing machines have long been a staple in the home. Whether a beginner or an experienced seamstress, being able to thread a sewing machine is an essential skill. Understanding how a sewing machine works and how to insert the thread correctly can help save time and frustration as you pursue your next project. From winding the bobbin, to setting the tension and inserting the needle, here is everything you need to know to thread a white sewing machine.

The first step to threading your sewing machine is to wind the bobbin. Before you fill the bobbin, it’s important to refer to the manual that came with your machine to make sure you are following the correct steps. Most sewing machines require you to insert the bobbin into the bobbin case and then secure it by wrapping the thread around it in a clockwise direction. Next, locate the bobbin spindle on the top of the machine, which will depend on the make and model of your machine as it may be in different locations. Insert the bobbin into the bobbin spindle, then pull the thread through the slot in the bottom to lock it.

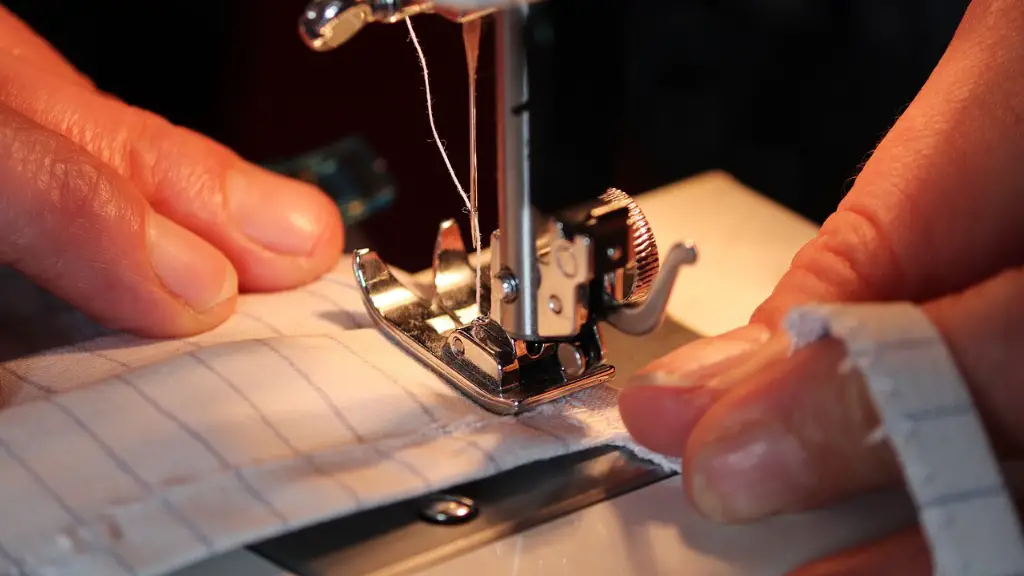

Now that the bobbin is ready to go, the next step is to thread the machine itself. Start by threading the spool of thread through the thread guide, then through the tension discs. Refer to your machine manual to double-check the settings as they can vary depending on the make and model. Once you’ve threaded the thread through the tension discs, you can now thread the needle. On most machines, the needle threader is a lever located just behind the needle. To use, place the thread into the eyelet of the needle threader, pull the lever down and the thread will be inserted into the needle. Next, using a small pair of scissors, trim the thread off near the eye of the needle.

Once the threading is complete, it’s time to test your sewing machine’s tension. Place a scrap piece of fabric underneath the presser foot and press the foot pedal to lower the needle. Make sure the needle is correctly threaded and the thread isn’t tangled. If the upper thread is pulled up, you may need to adjust the tension. Unless the setting notes otherwise, most sewing machines are set to a 3 or 4. You can adjust the tension by rotating the dial on the front of the machine.

When you’re ready to start sewing, there are a few things to remember. Firstly, be sure to keep the fabric moving, as stopping and starting can cause the stitches to come undone. Also, make sure to start stitching at the edge of the fabric as this will ensure a neat finish. Lastly, make sure to check the upper and lower threads before every seam as they can easily become tangled and lead to skipped stitches.

H2: The Benefits of Threading a Sewing Machine

Threading a sewing machine can be an intimidating process for a beginner, but learning how to do it properly can reap many rewards. Not only does it give you an understanding of how your machine works, but it can help you save time and frustration when sewing. Threading a sewing machine properly helps to ensure the fabric is evenly stitched and the seams are clean and secure. It can also help to ensure the tension settings are correct, which is particularly important when working with delicate fabrics such as silk and lace.

Non-professionals may not realise the importance of correctly threading and tensioning a sewing machine, but it can make a huge difference in the outcome of any project. With the right thread and tension, you can expect clean, even stitches that add a professional level of quality to your garments and bags. Threading and tensioning the sewing machine correctly is also important for optimising the function of the machine itself, as the thread helps to lubricate the internal parts of the machine, making it run more smoothly and efficiently.

Having a working knowledge of threading and tensioning your machine is a great way to save time and expand your sewing skills. Being able to understand how to insert the needle correctly and adjust the tension settings can help make the sewing process easier and help you create professional-looking garments and accessories.

H2: Troubleshooting Threading Issues

While threading a white sewing machine is a relatively simple process, there are a few common threading issues that can be easily fixed. Your thread may get stuck in the needle threader, in which case you should refer to your machine manual for specific instructions on how to fix this. If your thread isn’t winding onto the bobbin properly, ensure the thread is inserted correctly and check the tension settings. If the bobbin thread is loose, try increasing the tension.

As well as physical threading issues, there may be problems with the stitch quality. If your stitches are skipped or jammed, check the tension settings as they may be too tight or too loose. Your thread could also be fraying or breaking, in which case make sure the spool pin and thread guide are clean and the thread is inserted correctly. If the thread is still fraying, it is worth investing in a quality thread as it will be better for the machine and help to create better stitches.

When you encounter any sewing problems, it is worth checking the threading of your white sewing machine before attempting to fix any other issues. Threading issues can be the cause of many common problems and can often be resolved with a few simple adjustments.

H2: Care and Maintenance of a White Sewing Machine

Maintaining your sewing machine is key to optimising its function, as it can help to make the sewing process smoother, faster and more reliable. Sewing machines should be cleaned and stored in a safe space every time you finish working on a project. The feeds, feed dogs and presser foot should all be inspected for signs of wear and tear, and wiped down with a dry cloth. Your machine should also be regularly serviced by a professional to ensure everything is working correctly.

To prevent threading issues, regular maintenance is key. It is important to keep the thread guides and tension discs clean as any lint or dust build up can cause the thread to bunch up or refuse to insert correctly. Also, make sure to regularly oil the machine and check the tension settings as this ensures the thread is moving smoothly and efficiently.

In addition to regular care and maintenance, investing in the right supplies is essential for the functioning of the sewing machine. Quality thread is essential for the threading process and helps to prevent jams and skipped stitches. High quality thread is also better for the machine, as it is less likely to fray and cause thread build up in the tension discs.

H2: Storing Your White Sewing Machine

Storing your sewing machine correctly will help to extend its life span and prevent any unnecessary damage. A safe and dry storage space is recommended, and machines should be stored away from extreme temperatures, humidity and dust. It is also worth investing in a waterproof machine cover to help protect it from moisture or liquid spills.

It is also important to keep any other sewing items in a safe space, such as the bobbin, thread spool and needle. Store them away from direct sunlight, to avoid fading. If you are storing a thread spool on the machine, make sure it is placed securely, away from any moving parts, so that it doesn’t cause any jams or stitches.

As well as keeping all parts of the sewing machine in a safe space, it is important to refer to the instruction manual. This will provide essential information about how to properly handle and store your machine, to ensure it is working optimally for every project.

H2: Finding the Right White Sewing Machine

When choosing a new sewing machine, it is important to do your research and consider your individual needs. Selecting the right machine will depend on what type of sewing you plan to do and your skill level. If you’re an experienced seamstress, you may want to consider an industrial machine as these have more features and higher quality components. However, if you’re a beginner, an electromechanical machine will be suitable as they are easier to use and have more basic features.

When it comes to threading, some machines are easier to use than others. Look out for features such as automatic threaders, as these can make the threading process easier and faster. Machines with built-in tension controls can also help to adjust the tension setting quickly, and help to optimise the machine’s performance. Lastly, modern machines often come with LCD screens that provide instructions for threading and maintenance, so you can refer to this if you get stuck.

Investing in the right white sewing machine for your needs can save a lot of time and frustration, as it will enable you to thread the machine correctly and optimise the performance of your machine.