How to Thread the Bottom of a Sewing Machine

Threading a sewing machine is not as intimidating as it seems at first! All you need is a bit of practice and patience to get it right, as it can be a tricky process to get perfect. Luckily, there are a few tips and tricks to help make threading the bottom of a sewing machine easier.

Choose the Right Thread: The type of thread you use can make a difference in how smoothly the machine stitches. Generally, you’ll want to use a thread that is made of 100 percent polyester. This type of thread is stronger than other options, so it won’t break as easily. Plus, it is more resistant to fading and stretching out of shape.

Inspect The Bobbin: Before loading the bobbin in the machine, inspect it for any knots or tangles in the thread. A knot or tangle can make threading much more difficult and time consuming. Once you have ensured the thread is smooth and knot-free, you can continue to thread the machine.

Attach The Bobbin: Once you have chosen the bobbin and the thread to use, you can attach the bobbin. Start by loosening the top of the sewing machine and removing the bobbin case from it. Then, you can insert the bobbin into the case but make sure the thread is running in a counter-clockwise direction.

Thread The Bobbin Case: Place the bobbin case back in the sewing machine, being careful not to disturb the thread. Now, you can thread the bobbin case by passing the thread through the metal slit at the top of the case. Then, make sure there is no slack in the thread and that it is firmly fastened.

Begin Sewing: After the bobbin case is properly threaded and locked in place, you should be able to begin sewing. Pull the thread up from under the presser foot, and adjust the tension knob on the bobbin case as necessary. Now you should be ready to start sewing!

Stitch Selection

Now that the sewing machine is threaded and ready to sew, it’s important to choose the right stitch for the job. The type of stitch you choose will depend on the material you are working with and the type of garment you are creating.

Straight Stitch: The straight stitch is the most basic stitching technique and is used for basic garment construction and repairs. This stitch can also be used to join two pieces of fabric together, such as a hem or a seam.

Button Hole Stitch: The button hole stitch is used to create a hole in the fabric for button insertion. This stitch is best used on heavier fabrics, such as denim or leather, and requires a more delicate touch.

Zigzag Stitch: The zigzag stitch is a great option for creating decorative features on your garments, such as cuffs, hems and collars. This stitch is also great for mending small rips or tears in the fabric.

Adjusting the Tension

The tension on a sewing machine is important as it determines how tight the stitches are. The tension can be adjusted using the tension dial, which is located at the side of the sewing machine. Experimenting with the tension is a great way to get the perfect stitch.

Upper Thread: The upper thread should be set to a slightly higher tension than the bobbin thread. Generally speaking, the tension should be set so there’s no looping of the thread, but not so tight that the thread breaks easily.

Bobbin Thread: The bobbin thread should be set to a slightly lower tension than the upper thread, so that the upper thread is not pulled too tight. This ensures that the stitches are even and strong.

Cleaning and Maintenance

It is important to regularly clean and maintain your sewing machine in order to ensure it continues to produce high quality stitches. Regular cleaning can also help to extend the life of the machine.

Lubricating: Most sewing machines will require lubrication in order to ensure it functions properly. Refer to your machine’s user manual to find out how to properly lubricate it.

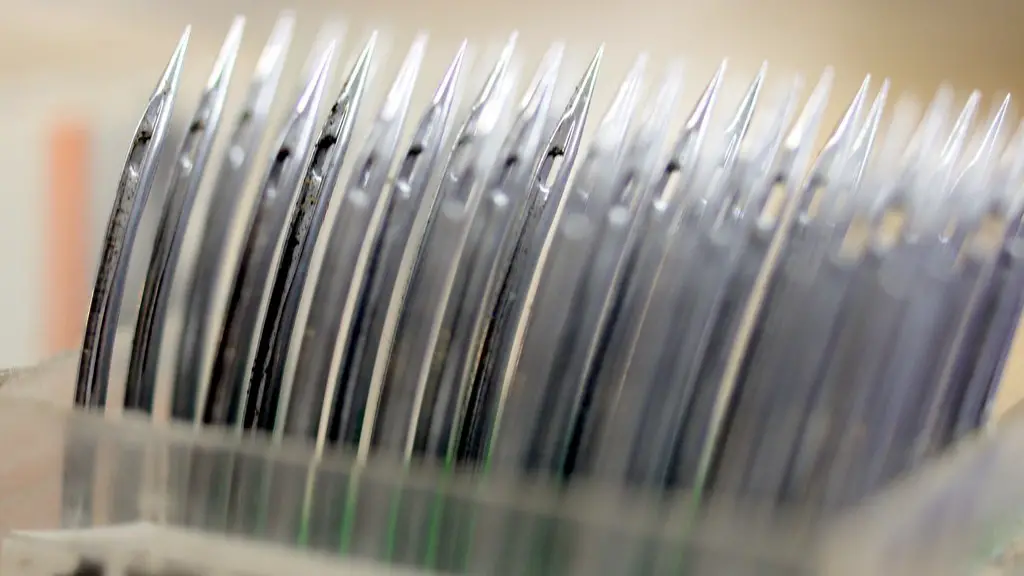

Cleaning: It is important to regularly clean the machine to prevent any build-up of dust or lint. Use a damp cloth to wipe away any debris and also clean the needle and presser foot if necessary.

Testing: Before every use, it is important to test the machine to ensure it is in proper working order. Make sure the bobbin is threaded correctly and the tension is set correctly, and practice sewing on a scrap piece of fabric.

Expert Advice

Getting advice from an expert is a great way to become more confident in threading and using a sewing machine. You can reach out to a local sewing expert for advice or even take an online sewing class.

Lessons: Taking an online sewing class or attending an in-person workshop can be a great way to get started with sewing. These classes will typically cover the basics of threading a sewing machine.

Consultations: You can also reach out to a local sewing expert for one-on-one advice and assistance. An expert can help you to understand the basics of threading, as well as answer any specific questions you might have.

Resources: There are also plenty of websites and books available that can provide information on sewing and threading. Doing your own research is a great way to become more familiar with the process.

Practice and Patience

Threading a sewing machine can seem daunting at first, but with a bit of practice, patience, and expert advice, anyone can learn how to do it. Think about what type of thread and stitch you need for your project and don’t forget to clean and lubricate your machine regularly. With time, you’ll become a master at threading and no project will seem too daunting!

Pressing The Fabric

Once you have threaded the sewing machine and made sure everything is working properly, it is time to move on to pressing the fabric. This is a crucial step, as it will help to smooth out any wrinkles and ensure your seams look professional and neat.

Types of Irons: There are a few different types of irons to choose from depending on what type of fabric you are working with. A steam iron works well for lightweight fabrics, while dry irons are better for heavier fabrics, such as denim and wool.

Preparing the Fabric: Before pressing your fabric, it is important to make sure it is clean and free of any wrinkles. To do this, start by ironing on the reverse side of the fabric, working your way towards the front. Then, let the fabric rest for a few minutes before beginning to press.

Pressing the Seams: Once your fabric is pressed, it’s time to move on to pressing your seams. Start by using your fingers to press out the seam allowance and then use an iron or ironing board to press the seam flat.

Pressing Cuffs and Collars: Cuffs and collars can be tricky when pressing, as the fabric tends to stretch out of shape. Start by using your fingers to press out any creases and then use an iron to press from the outside of the fabric. To make sure the shape stays in place, press from multiple angles.

Hemming Techniques

When sewing a garment, it is important to finish off the edges with a hem. This will make the garment look neat and professional, as well as prevent any fraying.

Hand Sewn Hem: If you are working with lightweight fabrics or thick fabrics, a hand sewn hem is often the best option. Start by folding the fabric over the desired length and then hand stitch the hem in place using a blind stitch or a slip stitch.

Machined Hem: For thicker fabrics, a machined hem may be the best option. Start by sewing a straight stitch around the hemline, then press the fabric to neaten it up and stitch a second row of straight stitching to secure it in place.

No-Sew Hem: For those new to sewing or working with delicate fabrics, a no-sew hem is a great alternative. Start by pressing the hemline and then use fabric tape or glue to secure it in place.

Troubleshooting

When working with a sewing machine, it is important to know how to troubleshoot it if something goes wrong. Below are a few common problems and their solutions.

Machine Not Working: If the machine isn’t working, it could be a sign of an electrical issue, a jammed bobbin, or broken thread. Start by inspecting the bobbin and thread and then check the machine’s power cord and fuses.

Weak Stitches: If the stitches are weak, this could be a sign of incorrect tension or a dull needle. Start by adjusting the tension and then check the needle for any damage. If necessary, replace the needle with a new one.

Stitches Too Large: If the stitches are too large, this could be a sign of a loose thread tension or a dull needle. Start by inspecting the thread and needle, and adjust the thread tension if necessary.