Types of Sewing Needles

Sewing machines use different types of needles for different types of fabrics and projects. It is important to choose the right type of needle for the fabric being sewn. The most common types of sewing machine needles are universal, stretch, denim, and embroidery. Universal needles, which can be used on most fabrics, are commonly used for general sewing. Stretch needles have a special scarf designed to lessen the skipped stitches that occur when stitching stretch materials. Denim needles have sharper points and are usually better for heavy fabrics. Embroidery needles have a bigger eye that allows for threading of metallic threads, heavier cotton threads, multiple strands of thread, and decorative ribbons.

Parts of a Needle

The components of a sewing machine needle include the shaft, the point, the scarf, and the shank. The shaft is the long slender part of the needle that encloses the point, which should be located at the tip. The point is the part of the needle that goes into the fabric to make a pathway for the thread in the bobbin hook. The scarf is an indentation in the needle shaft so the hook can properly pull the loop of the thread up through the fabric. The shank is the part of the needle that fits into the needle holder of a domestic sewing machine.

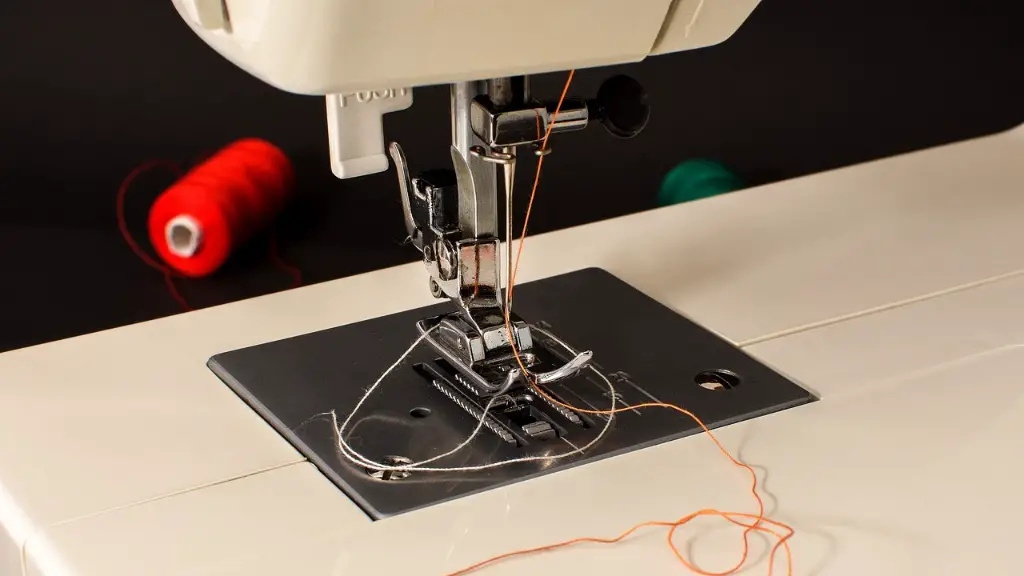

The Needle Position

In order for a needle to make a stitch at the right position, it must be properly positioned in the needle holder. The flat side of the needle should face to the back of the machine, and the round side should face toward the front. The needle holder should be at the same height as the presser foot and the presser foot lever should be in the down position. Ensuring that the needle is located in the far left side of the needle holder will help to make the stitch line straight.

The Needle Moving Through the Fabric

When the sewing machine is turned on, the needle will move up and down and make a stitch in the fabric. It works by a guide mechanism which moves the needle along a precise path. As the needle moves down, the thread from the bobbin gets sucked up by the hook underneath the needle. The hook then wraps the thread around the needle and pulls it back up through the fabric. This loop is held in place by the tension of the upper and lower threads, creating the stitch.

Needle Care and Maintenance

To keep the sewing machine working properly, it is important to inspect the needle regularly and replace it when needed. It is highly recommended to replace the needle after every 8 hours of sewing to reduce the risk of skipped stitches or torn fabric. Needles should also be changed according to the type of material and project being sewn. Needles should also be stored in a dry, dark place and not left in the machine overnight to avoid rusting or breakage.

Picking the Right Needle

It is important to select the right needle for the type of fabric and project being sewn. Different types of needles work better with certain fabrics, such as stretch needles or denim needles. Universal needles should never be used on stretch fabrics as they can cause skipped stitches. Embroidery needles are recommended for decorative stitching, while topstitching needles can be used for any heavy weight fabrics.

Factors Affecting Needle Durability

The durability of a needle is impacted by the type of fabric, thread, and needle being used. Some fabrics, such as denim or heavy weight fabrics, can cause needles to wear out quicker than lighter fabrics. Similarly, using certain types of threads, such as metallic threads or multiple threads, may cause a needle to wear out quicker. Choosing the right needle for the fabric and thread being used will help to increase the longevity of the needle.

Seam Allowances and Needles

Seam allowance is the measurement between the edge of the fabric and the stitching line. The seam allowance has an impact on the performance of the needle. Needles that are too long may pierce through the fabric, while needles that are too short may cause skipped stitches. Care should be taken to select the correct size needle for the seam allowance being used.

Seam Strengtheners and Needles

Seam strengtheners are used to increase the strength and longevity of a seam. They are usually used for fabrics that are prone to fraying and require extra strength. Needles for seam strengtheners should be chosen based on the type of fabric and seam allowance. Needles that are too long may cause skipped stitches, while needles that are too short may not penetrate the fabric fully. Choosing the right type of needle for the fabric being sewn is important for creating strong, durable seams.

The Impact of Needle Thicknesses

Needles come in various thicknesses which can have a major impact on the stitch quality of a project. Needle thick nesses should be matched to the thread size and fabric weight in order to ensure that the needle is able to properly penetrate the fabric and secure the thread. Needles that are too thick will cause damage to the fabric while needles that are too thin may cause skipped stitches.

Seam Types and Needles

Different types of seams can be created with a sewing machine. Common seam types include French seams, flat felled seams, and Hong Kong finish seams. Each of these seam types requires the use of the correct type of needle and the appropriate stitch length. French seams need a medium length stitch with a fine needle, while flat felled seams require a long stitch length with a heavy duty needle. Hong Kong finish seams should be sewn with a wide zigzag stitch using a medium or heavy duty needle.

Troubleshooting with Needles

It is important to inspect the needle regularly for any signs of damage. If the machine is having trouble making a stitch, it could be due to a broken or damaged needle. Needles can be further inspected under a microscope to check for dull points, burrs, nicked surfaces, and other imperfections. If a needle is found to be damaged it should be replaced with a new one to ensure a clean, smooth stitch.