Causes of Needle Failure

The life of a sewing machine needle depends upon several factors. Needles can be blunt very quickly if they are used on the wrong type of fabric or if they are too fine for the thread weight being used. Improperly set tension will also cause needles to shatter or bend. In addition, heat build-up from excessive speed and improper lubrication can also contribute to needle failure. In order to make sure that your needle lasts its full lifespan, it is important to use the correct thread weight, tension, and needle size for the project at hand.

Replacing the Needle

The frequency of needle replacement depends on the type of sewing being done and the quality of the needle. High-quality needles will last longer than lower-grade needles and can be used multiple times before they need to be replaced. If there is no visible damage to the needle, it can usually be re-used multiple times. However, if the needle is blunt or bent, it should be replaced immediately. In general, needles should be replaced at least four times a year. However, this can vary depending on the type of sewing being done.

What Type of Needle to Use

When it comes to choosing a sewing machine needle, there are a few things to consider. The most important factor is the type of fabric being used for the project. Different fabrics require different types of needles, so it is important to select the needle that is best suited to the fabric being used. A sharp needle is best for most woven fabrics, while an overlock needle is recommended for knits and stretch fabrics. Universal needles are the most popular and work for most fabrics, but they are not ideal for heavier fabrics.

Correct Thread Tension

In order to ensure that the needle lasts its full lifespan, it is important to make sure the thread tension is correct. The tension can be adjusted by turning the screw clockwise to increase the tension or counterclockwise to decrease the tension. When the tension is correct, the thread should loop around the needle, while the needle should slide through the fabric relatively easily. If the thread pulls too tightly, the needle may bend or break.

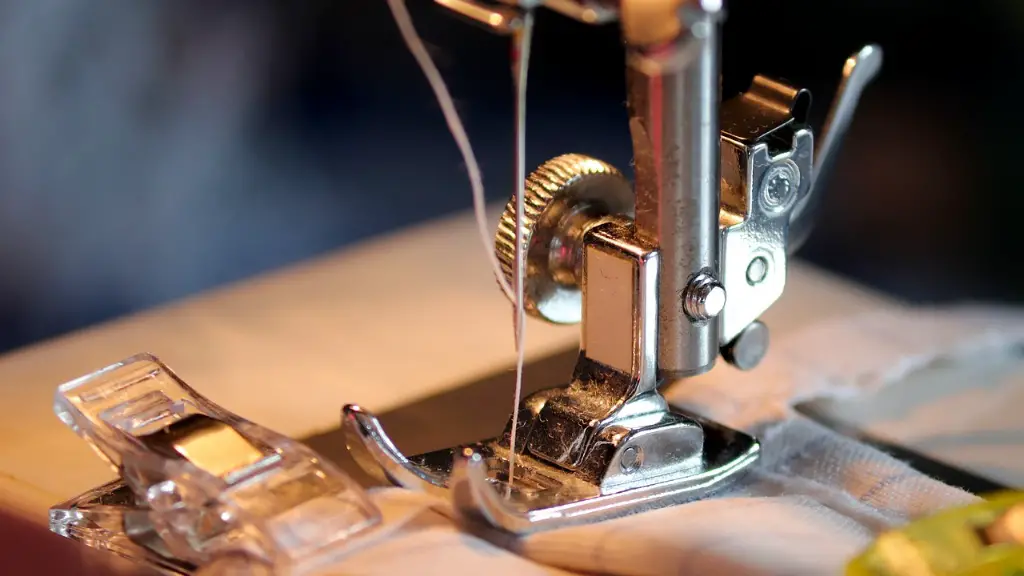

Lubrication of the Needle

In order to prevent heat build-up, the needle should be regularly lubricated. Most modern sewing machines come with automatic needle lubrication systems, but some machines may require manual lubrication. Needle lubricant can be purchased from most fabric and craft stores and it is important to make sure that this is done regularly in order to ensure that the needle lasts its full lifespan.

Storing and Maintaining Needles

Needles should be kept in a protected container away from dust and moisture. Needles that have been used should not be re-used until they have been checked for any damage and properly lubricated. It is important to remember to remove the needle after each project, as leaving it in the machine may dull or damage the needle.

The Cost of Sewing Machine Needles

The cost of a sewing machine needle will depend on the type and quality of the needle. Generally, the higher the quality of the needle, the more expensive it will be. For example, Schmetz needles are high-quality German-made needles, and they can cost anywhere from a few dollars to more than $100. In contrast, lower-grade needles are available for as little as a few cents for a pack of five.

Types of Needles

There are several types of needles available for sewing machines, and each type is suited to different projects. Universal needles are the most common and are suitable for most fabrics. However, unique needles may be required for more specific projects such as working with leather, denim, and velvet. Ballpoint needles are specifically designed for use with knit fabrics, while twin needles are ideal for creating decorative stitches.

Thread Weight and Needle Size

The thread weight and needle size play an important role in how long a needle lasts. Generally, it is best to use the smallest needle size possible in order to reduce the risk of damage. In addition, heavier threads require larger needle sizes than lighter threads. When selecting a needle size, it is important to ensure that the size is appropriate for the weight of the thread being used.

Tips for Optimal Needle Life

Make sure the thread tension is correct. Use the correct type of needle for the fabric being used. Lubricate the needle regularly. Replace the needle when it becomes dull or bent. Store needles in a protected container. Don’t leave the needle in the machine after use. Inspect the needle before re-using it.

Caring for Your Sewing Machine

In order to get the most out of your needle, it is important to regularly care for your sewing machine. This includes checking the tension periodically and cleaning the machine after each use. In addition, the needle should be checked for any damage and replaced as needed. Regularly lubricating the machine will also help to keep it running smoothly and help the needle last its full lifespan.

Avoiding Needle Damage

In addition to regular maintenance, there are a few things to keep in mind in order to avoid damaging the needle. It is important to use the correct type of fabric and needle size for the project, as well as the correct thread weight and tension. Avoid applying too much pressure when stitching, as this can cause the needle to become blunt or bent. Finally, never use the same needle for different types of fabrics as this increases the risk of damage.