As every sewer would know, how you set your sewing machine can be the difference between a professional-looking garment and a homespun piece. Industrial sewing machines are the ones used for mass garment production, so getting the stitch length right is essential for any confident sewer. Here are some tips on how to adjust the stitch length in an industrial sewing machine.

First of all, you’ll need to identify which type of stitches you need to use. Different fabrics require different kinds of stitches, such as overlock, zigzag, straight, and others. Once you have identified the type of stitch you need, you’ll need to adjust the needle position accordingly. Make sure that the needle is positioned so that it’s aligned with the line of stitching that you are creating.

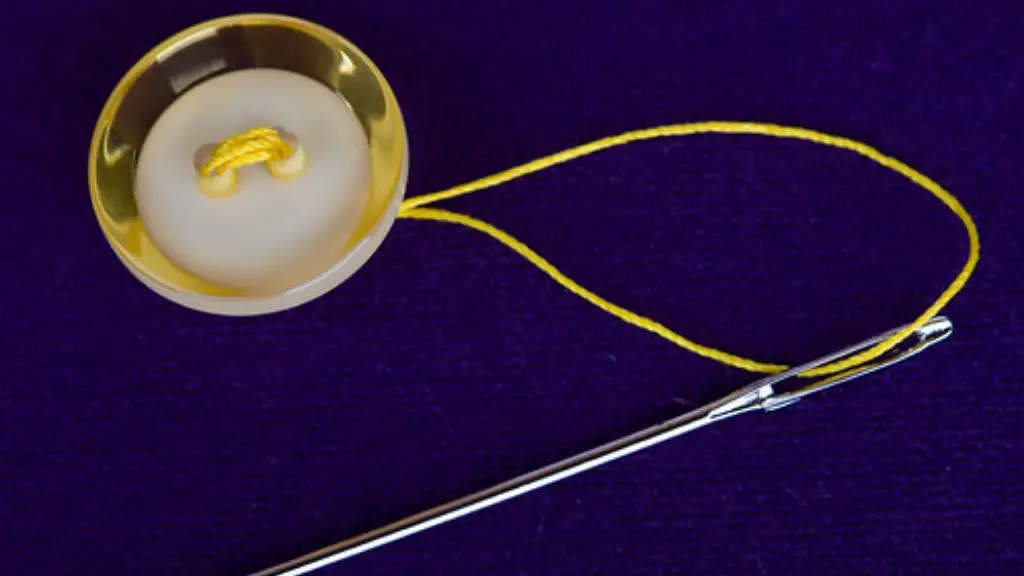

Next, adjust the tension of the thread. The tension of the thread should be adjusted according to the weight of the fabric. If the fabric is too heavy, the tension should be increased. If the fabric is too light, the tension should be decreased accordingly. Remember to test the tension on a piece of scrap material before use.

Third, set the correct stitch length. After setting the tension, you need to make sure that the stitch length is correct for the material you’re working with. If the stitch is too long, it will make the seam bulky and weak. On the other hand, if the stitch is too short, it can result in bulky bobbin threads and stitch breakage.

Fourth, take into account the material thickness. Different types of materials call for different stitch lengths. For example, lightweight fabrics may need shorter stitches than heavyweight fabrics. It’s important to consider the thickness of the fabric when adjusting the stitch length.

Finally, adjust the feed. The feed is the mechanism that moves the fabric under the needle of the machine. If the feed is too slow, the fabric won’t feed through the machine properly, which can result in uneven stitching or skipped stitches. However, if the feed is too fast, it can result in bunching and puckering of the material.

Stitch Troubleshooting

When adjusting stitch length on industrial sewing machines, it’s important to pay attention to any problems that may arise. Common issues include skipped stitches, thread breakage, uneven stitches, and puckering of the fabric. Skipped stitches are usually due to an improper tension or incorrect needle position. Thread breakage can be caused by poor quality thread, incorrect threading, or an overly tight tension. Uneven stitches and puckering may be caused by an improper feed or stitch length.

It’s important to troubleshoot any issues that may arise when adjusting the stitch length. The first step is to gently examine the fabric and look for signs of damage, such as skipped stitches or threads catching on the edges of the fabric. If this is the case, check to make sure that the thread and needle are properly positioned, and the tension is correctly adjusted.

If the problems persist, examine the feed mechanism. If the feed is too slow, it could cause the fabric to bunch up or slide through the machine too quickly. On the other hand, if the feed is too fast, it can lead to puckering and an uneven stitch tension. Once you have identified the problem, adjust the feed accordingly.

Thread Tension

One of the most important aspects of adjusting the stitch length on an industrial sewing machine is the tension of the thread. If the thread is too loose, it can result in an uneven stitch and skipped stitches. If the thread is too tight, it can cause the fabric to bunch up and cause puckering. It’s important to adjust the thread tension according to the instructions in the user manual.

The tension of the thread should also be adjusted according to the material you’re working with. If the fabric is lightweight, the tension should be set to a lower level. Conversely, if the fabric is heavy, the tension should be increased. Additionally, it’s important to test the tension on a scrap of fabric before beginning the project.

Finally, it’s important to check the thread tension from time to time during the project. If the tension becomes too loose or too tight, it can cause the stitch to become uneven or skip. To address this issue, simply adjust the tension accordingly and continue with your project.

Needle Position

Another important aspect to adjust is the position of the needle. If the needle is set too low, it can cause the fabric to bunch up and the carding to be uneven. On the other hand, if the needle is set too high, the material can stretch, resulting in an uneven stitch. It’s important to adjust the needle to the correct position according to the material you’re working with. If the material is lightweight, the needle should be positioned lower. If the material is heavy, the needle should be positioned higher.

The position of the needle should also be adjusted according to the stitch length. For example, if you’re working with a straight stitch, the needle should be positioned so that it’s aligned with the line of stitching. On the other hand, if you’re creating a zigzag stitch, the needle should be positioned slightly to the side of the line of stitching.

Adjusting the position of the needle can be tricky, but it’s important to take the time to make sure that it’s properly positioned. Once the needle is positioned correctly, it’s much easier to adjust the stitch length and make sure that the fabric is fed through the machine correctly.

Conclusion

Adjusting the stitch length on an industrial sewing machine requires attention to detail and a good understanding of the various components of the machine. It’s important to identify the type of stitch you need to use and adjust the needle and thread tension. Additionally, it’s important to adjust the feed and the position of the needle. Troubleshooting any issues that may arise is also important, as this can help ensure that the stitches are even and the fabric is fed through the machine properly. With a bit of practice, sewers can learn to properly adjust the stitch length on industrial sewing machines and create professional-looking garments.