Tools Needed

To adjust the tension on a Singer Prelude Sewing Machine, you will need the proper tools. Depending on your particular sewing machine model, you may need a variety of allen keys, hex keys, or Phillips head screwdrivers. If you are not sure whether or not you have the right tools, it is best to consult the manual accompanying your sewing machine and any schematics that explain the process in detail.

Before attempting to adjust tension on your machine, you should also invest in a screwdriver set and a good quality draft gauge to help you adjust the tension correctly. When using any tools near the sewing machine, ensure that they are correctly secured to the machine. When using any loose accessories, take extra precaution to ensure that no damage is done to your machine.

Threading the Machine Properly

When it comes to adjusting the tension on your machine, the first step is to properly thread the machine. This involves properly threading the machine’s various parts in a specific order. Many issues with tension can be avoided by making sure that your machine is threaded correctly. Double check to make sure that the thread is properly looped through the tensioning discs, correctly passed through the tensioner, and correctly positioned in the bobbin winder.

When threading the machine, also take into account the thickness of the thread being used. Thicker thread will require a higher tension setting than thinner thread. Make sure that the threading is matched according to your desired tension settings.

Adjusting the Tension Discs

The tension discs are the small plates located at the front of your machine. These discs hold the thread in place, and can be adjusted to change the amount of tension in the thread. These discs should be screwed in or out depending on the type of thread being used. The tension discs can be adjusted slightly with a screwdriver to create a slightly tighter or looser thread. It is important to remember that the discs should be adjusted in an alternating pattern.

When adjusting the tension discs, it is essential to keep in mind that too much tension can damage your machine. If the tension is too loose the thread will not be pulled properly through the fabric, and if it is too tight the thread will be pulled too tight when the machine is stitching. As such, it is important to carefully adjust the tension discs to achieve the desired tension.

Adjusting the Tension Dial

The tension dial is located on the front of the machine, and is used to adjust the tension of the thread. The dial acts as a guide to setting the tension of the thread, and can be adjusted to tightly or loosely create a certain amount of tension. As the tension dial is adjusted the tension discs will move with it, creating the desired amount of tension in the thread.

When adjusting the tension dial, take care not to overtighten the thread. Too much tension can cause the thread to break and may cause damage to your machine. As such, it is important to adjust the tension dial slowly and cautiously.

Cleaning and Lubricating the Machine

Cleaning and lubricating your machine is essential for the long-term health of your machine. It is important to ensure that your machine is cleaned regularly to remove any dirt or debris that may affect the tension in your thread. Also, it is important to lubricate the machine regularly to ensure that it is running at its optimal performance.

If the tension in your thread continues to be an issue, it may be due to a lack of regular cleaning and lubrication. If this is the case, it is best to take the machine to a certified mechanic to have it serviced and properly lubricated.

Checking the Bobbin Winder

Another area that can affect the tension in the thread is the bobbin winder. The bobbin winder is located on the machine’s side, and is used to feed the thread into the machine. It is important to ensure that the bobbin winder is in good working condition, as it can cause tension issues if it is worn or defective.

To ensure that the bobbin winder is functioning properly, check the tension release knob. This knob should be in the ‘OFF’ position to ensure that the bobbin winder works properly. It is also important to check that there is no debris stuck in the bobbin winder, as this can create tension issues.

Using Thread Guides to Assist Tension Adjustment

Using thread guides can make adjusting tension on your machine much easier. Thread guides come in many different sizes, and can make adjusting the tension of a thread much simpler. By using thread guides you can easily ensure that the tension is just right. Thread guides also help to reduce the amount of strain placed on the thread, as they help to ensure that the thread passes through the machine correctly.

It is important to remember that thread guides are not a replacement for proper tension adjustment. It is still essential to adjust the tension discs and the tension dial correctly to ensure that the thread is tensioned correctly.

Testing the Tension Settings

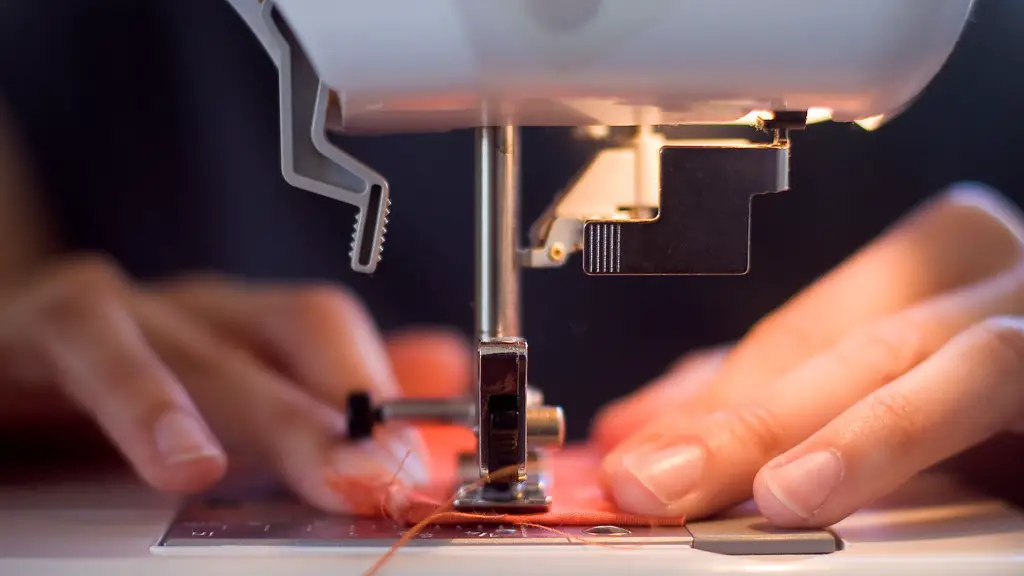

Once you have adjusted the tension on your sewing machine, it is important to test the settings before continuing. A good way to test the tension settings is to stitch a piece of scrap fabric together. During the process, check that the tension is just right and that the thread is being pulled correctly through the fabric.

If the thread is too tight, then the tension discs and tension dial should be adjusted accordingly. Likewise, if the thread is too loose then the tension discs and tension dial should be adjusted to create a snugger fit. If the tension seems to be off, then it may be necessary to repeat the threading process from the beginning.

Daily Maintenance

Adjusting tension on a sewing machine can be a tricky business, and therefore it is important to practice a regular maintenance routine. Regularly checking the tension discs and tension dial, cleaning the machine and lubricating it, and checking the bobbin winder are all important tasks that should be completed as part of regular maintenance routines.

It is also important to regularly test the tension settings, as this will ensure that the tension is set correctly. If the tension is off, then appropriate adjustments should be made. When it comes to adjusting tension on a sewing machine, it is always better to be safe than sorry.

Consulting a Professional

If the tension is still off after making adjustments, and the problem persists, then it may be best to consult a professional. A professional repair technician can quickly pinpoint any issues that are causing tension problems, and can make sure that your sewing machine is in good working condition. Sometimes small issues can cause major problems with tension, so consulting a professional can help to ensure that your machine is running at its optimal performance.

It is also important to regularly check the manual accompanying your sewing machine for instructions and advice on adjusting tension. This manual should contain detailed instructions on how to accurately adjust the tension on your specific machine model, and should be consulted if any problems arise.

Troubleshooting

It is important to pay attention to any issues that come up when sewing with your machine, as they can easily be indicative of tension issues. Problems such as thread breaking, fabric puckering, or skipped stitches all point to tension issues, and therefore should be addressed immediately.

If the tension is still off after attempting to adjust it, it may be necessary to troubleshoot further. If this is the case, make sure to check the condition of the thread, as it may be too thick or worn to be pulled through the fabric. Similarly, check the condition of the needle, as an old needle may cause tension issues.

Making Adjustments Over Time

It may take some time and patience to get the tension on your Singer Prelude Sewing Machine just right. Even after making the necessary adjustments, it is still important to monitor the tension regularly to ensure that it is set correctly. Over time, adjustments may need to be made as the thread used changes or the tension settings require slight changes.

Adjusting the tension on a Singer Prelude Sewing Machine is not a difficult task, as long as the correct tools are used and the instructions are followed carefully. With a little bit of practice and patience, it is easy to get the tension on your machine just right.