Basics of Catching the Bottom Thread

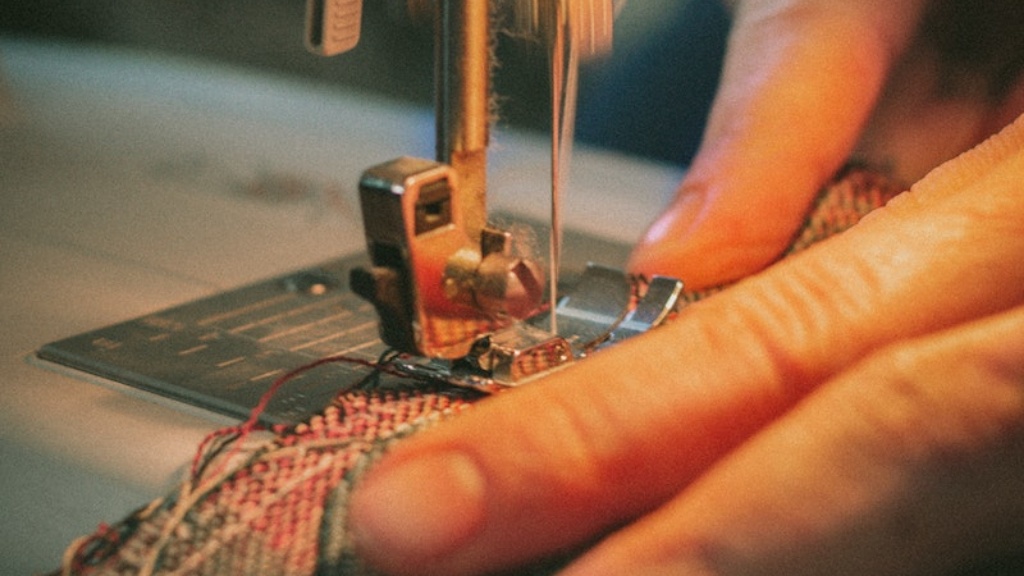

Threading a sewing machine can be a daunting task for those new to sewing. But with a few basic instructions and some practice, most people can catch the bottom thread on a sewing machine in no time. First and foremost, it is important to note that the type of sewing machine you have will determine how you thread it. Once you have familiarized yourself with the type of thread you need, the steps to threading a sewing machine are generally the same regardless of the type of machine.

Before you begin, it is essential that you remove the presser foot and the Bobbin. To begin threading, use the spool pin to hold the thread in place. You should then move the thread around the upper tension dial and thread guide, passing the thread through the eye of the needle. After threading the needle, move the thread to the take up lever. This lever moves the thread up and down, pulling the thread through the tension discs and the looper, which helps the thread to make a loop. If done correctly, the lower thread is now looped through the needle and the looper.

Once the thread is looped through the needle and the looper, it’s time to catch the bottom thread with the bobbin case. Begin by pushing the bobbin winder spindle to the right and inserting the bobbin into the case. Ensure the thread is in the right direction, and then pull the thread through the slot. Hold the bobbin case with your right hand and tug the thread with your left. This will allow the thread to cross the spring-loaded tension disc on the bobbin case. Now, while holding the thread tautly, move the bobbin case clockwise and then counterclockwise until you hear the click that indicates the bobbin case is snapped securely into place.

Once that is done, it is time to guide the thread onto the bobbin. To do this, take the flat side of the thread and guide it around the outside, followed by the thread from the inside. You may then need to use your hands to guide the thread across the bottom circle and inside the groove of the bobbin case. Now that the thread is securely attached to the bobbin, you can begin winding. While doing this step, make sure the thread is running in the same direction as the arrow marked on the body of the sewing machine.

Once the bobbin is full, it is time to insert it into the machine. This process varies by machine, so make sure you have read the directions for your particular model. Generally, the bobbin should be inserted in the same direction as the arrow on the machine, and should be placed with the thread running in a clockwise direction. Once the bobbin is inserted, the remaining thread should be pulled to the top of the machine. Now that you have caught the bottom thread, it is time to set the tension (a step that is essential for any project).

Once you have set the tension and everything is working properly, you can start sewing. With some practice, you should be able to master threading a sewing machine in no time. And once that’s done, the world of fashion and design is your oyster!

Using the Right Thread for Your Project

When it comes to threading a machine, it is important to use the right type of thread for the project. Different thread types are suitable for different fabrics and types of stitching, so ensure that you are using the correct type for the project you are working on. For example, heavier threads should be used to sew heavier fabrics, while finer threads should be used to sew finer fabrics. Additionally, different threads require different tension settings, so make sure to read the directions for each thread type you are using.

It is also important to note that threading a sewing machine requires some patience. Different machines have different methods of threading, so be sure to read the directions thoroughly before attempting to thread your machine. In addition, each thread type may require a different tension setting, so make sure to familiarize yourself with the necessary settings before you begin to thread. Lastly, double-check to make sure the thread is running in the correct direction before you start to sew, as this will ensure that the thread will be pulled correctly through the machine, resulting in better quality stitching.

Using the correct thread for the project you are tackling is essential to ensure proper threading. If the wrong type of thread is used, it can result in snags or jams, which can cause the machine to malfunction and waste valuable time. Additionally, when attaching the thread to the needle and the looper, it is important to take care, as the wrong direction of the thread may cause undue strain on the machine and affect its performance.

Finally, when you purchase a new spool of thread, it is important to note that some threads may require light cleaning. Anything from lint or dirt in the thread may cause jams and other malfunctions in the machine, so it is essential to inspect the thread before using it. Some light cleaning with a damp cloth may be necessary to ensure that the thread will not cause any issues.

Advantages of Using the Right Thread

Using the correct type of thread for your project can provide a number of advantages, both for the quality of your project and for the machine itself. For example, using the right thread can improve the quality of your stitching, making the seam stronger and more durable. Additionally, using the right type of thread can prevent the machine from jamming, as wrong tension or incorrect thread types can cause the machine to push the thread through too fast, resulting in tight and weak stitches.

Using the right thread can also prevent damage to the machine. Incorrect tension settings, thread types, and directions of threading can cause the machine to malfunction and need repairs. In contrast, using the right type of thread can reduce the strain on the machine, leading to fewer repairs and longer-lasting performance.

Finally, taking the time to choose the correct thread and ensure it is correctly threaded can save a vast amount of time and energy. Any project utilizing the wrong thread or a thread that has been stretched too tightly can result in loose or weak stitches, which can take a long time to repair. Furthermore, improper threading can cause the machine to jam, forcing you to start the threading process from the beginning. Therefore, paying attention to the type and direction of thread can save a great deal of time and effort.

Caring For Your Sewing Machine

While using the right type of thread is essential for threading the machine correctly, there are other steps that should be taken to ensure the machine lasts a long time. First and foremost, it is important to inspect the machine regularly to make sure there is no dirt or lint underneath the needle plate. In addition, checking the machine for cracks or frayed wires can help prevent dangerous malfunctions.

It is also important to clean the feed dog on a regular basis. The feed dog is an important part of the machine, as it helps regulate the thread tension and properly pull the fabric through the machine. Cleaning the feed dog is quick and easy, and can be done by simply inserting a cloth into the area and carefully wiping off any dirt or debris.

Another key component of sewing machine maintenance is lubricating the components as needed. Most sewing machines need to be lubricated every two months or so, depending on how frequently they are used. Be sure to read your manual for the recommended lubricant for your machine, as some machines require specific types of oil. In addition, it is important to lubricate all parts of the machine, including the shuttle hook and the disconnect lever.

Lastly, be sure to properly store the machine when not in use. This includes unplugging the machine, winding the remaining thread, and ensuring the presser foot is in the up position. Also, make sure to cover the machine with a protective cloth to prevent dust accumulation. With regular maintenance and use of the right thread, your sewing machine should last a long time.

Conclusion

Catching the bottom thread on a sewing machine can be a daunting task for those new to sewing. Although it is important to read the instructions for your particular machine and adjust the tension as necessary, a few basic instructions and some practice should have you catching the bottom thread in no time. Furthermore, taking the time to prepare the thread properly, choose the right type for your project, and maintain your sewing machine regularly can help ensure that your machine functions properly for years to come.