Clean Machine

It’s not always easy to change the direction of a sewing machine. Some machines are set to run in one direction only, and this can be difficult for the novice sewer. But with a little patience and some good advice, it’s possible to successfully change the direction of a machine. Knowing how to do this correctly can save you time and frustration – and help produce beautiful results.

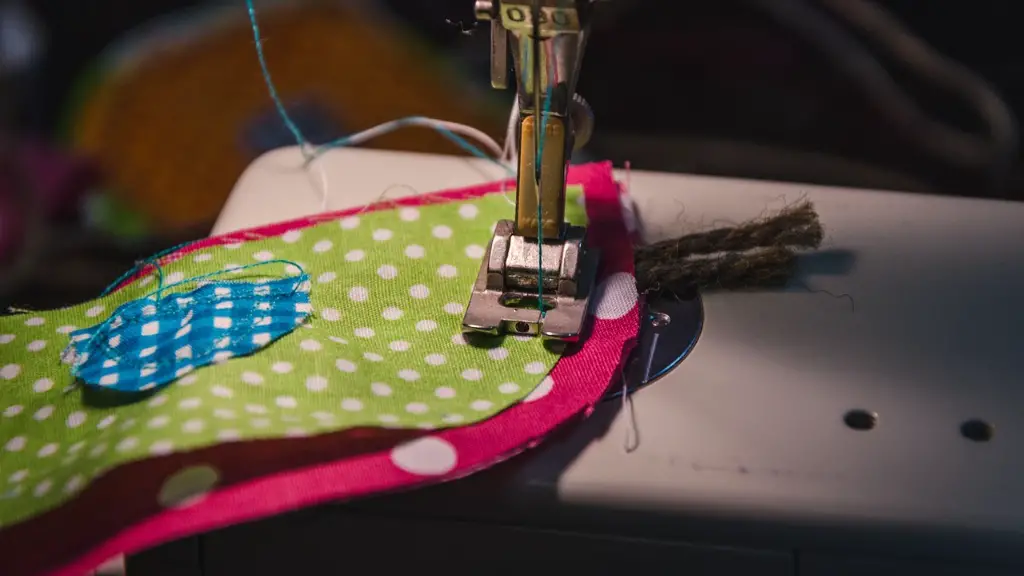

Before making any adjustments to your machine, it is absolutely critical to properly clean and prepare it before working. Make sure that you inspect it thoroughly for dirt, dust, thread residue, and any other debris that may have accumulated. Also, be sure to check your machine oil level if you have one. All machines, regardless of the manufacturer, can benefit from a routine maintenance check by a qualified technician.

Test the Machine

Once you have completed the cleaning process, it’s time to test the machine by running it in the new direction. If the machine runs smoothly, then adjusting the direction is quite simple. First you must identify the location of the changeable gears – this will vary depending on the machine model. For example, some machines will have a reversing switch on the side of the case, while for others this may be located near the tension disc.

Once you have located the correct location, your next step is to carefully listen and observe the machine. If you find that the machine is not running smoothly, it is important to take the time to adjust the tension on the machine. This process may require some trial and error before the desired results are achieved, so patience is key.

Ask for Help

If you are still having difficulty changing the direction of your machine after following the previously mentioned steps, it may be time to consult with a professional sewing machine technician. They have the skill, experience, and expertise to help you get the job done right.

It is also worth considering the possibility of purchasing a quality machine that allows the user to easily switch direction. Many high-end models feature adjustable gears, which can make the process much easier. Additionally, some machines also come with a built-in instruction manual or guidebook. By taking the time to read these, you can learn how to successfully adjust the direction without any external help.

Be Safe

Finally, it is important to remember to always exercise caution when changing the direction of a machine. Be sure to unplug the machine before making any adjustments, and wear proper safety equipment (gloves, eye protection). If you are unfamiliar with any part of the process, do not attempt to do it on your own; seek professional assistance instead.

Different Types of Machines

Changing the direction of a sewing machine largely depends on the specific model. Some machines may require the user to make manual adjustments, while others have features that allow the user to easily switch direction. Be sure to read the instruction manual thoroughly to determine what type of adjustments are necessary to change the direction of your machine.

When changing the direction of a servo-driven machine, it is important to be aware of some of the potential risks. These include machine overload, heat build-up, and wear on the servo-drive components. To reduce the likelihood of any of these issues, it is recommended that the user conduct regular maintenance checks and utilize quality servo-drive components.

Tension Settings

If tension adjustments are necessary when changing the direction of a machine, it is important to understand how tension settings can affect the quality of the finished product. Poor tension can lead to many problems, such as skipped stitches and uneven seams. To obtain the best results, the tension level should be set correctly prior to adjusting the direction.

When setting the optimum tension, it is important to consider the type of fabric being used, the size of the thread being used, and the type of stitches the machine is capable of producing. An experienced technician may be required to accurately set the tension to the right level.

Maximizing Efficiency

Changing the direction of a sewing machine is an important skill, and one that can be difficult to master. Fortunately, with the proper tools, knowledge, and safety precautions, the process can be much easier. By taking the time to understand the basics of how to change the direction of a sewing machine, users can maximize their efficiency and produce better-quality garments with less effort.

Lastly, it is important to note that depending on the type of machine and the fabric being used, it may be necessary to adjust the tension settings regularly throughout the process. Properly managing the tension can lead to better results, faster production times, and improved accuracy.

Software Solutions

Many modern high-end sewing machines are now equipped with software that can assist users in changing the direction of their machine with ease. This type of software allows users to program their machine to run in different directions at different speeds, making the process of changing directions much more efficient.

The software also provides users with a variety of settings and features, including customized speed and tension control, automatic stitch recognition, and built-in patterns. Additionally, some software solutions also offer a variety of maintenance and troubleshooting tools. By taking advantage of these features, users can ensure their machines are running at peak performance.

Maintaining the Machine

Another important aspect of changing the direction of a sewing machine is proper maintenance. Routinely checking the needle and other machine components is essential for best results. Additionally, it is important to regularly inspect the machine for signs of wear and tear. Making sure that all moving parts are properly lubricated is also key.

Another important maintenance step is to regularly check the tension settings. Improper settings can cause skipped stitches and other issues, so making sure that the settings are correct at all times is vital for success. Additionally, if the machine is not being used for a significant period of time, it is important to unplug it, to ensure safe and effective operation at all times.

Machine Settings

The final step in changing the direction of a sewing machine is to adjust the settings. Many high-end machines have a variety of adjustable settings, such as speed and tension, that can be used to customize the machine’s performance. Additionally, some machines may also have other features such as automatic thread cutters and stitch counters. Taking the time to familiarize yourself with these features can save you time and effort in the long run.

It is important to remember that proper machine settings are critical for best results. If the settings are incorrect, it can lead to frustration, defects, and wasted time. Additionally, turning the machine on and off too frequently can affect its performance, so it is important to find a balance between production speed and machine longevity.