An industrial sewing machine needle is a specialized tool that is designed for use with a particular type of sewing machine. Needles come in different sizes and shapes, and they are made of different materials depending on the type of sewing machine they are designed for. In order to change an industrial sewing machine needle, you must first identify the type of needle that is required for your machine. Once you have identified the correct type of needle, you can then proceed with changing the needle on your machine.

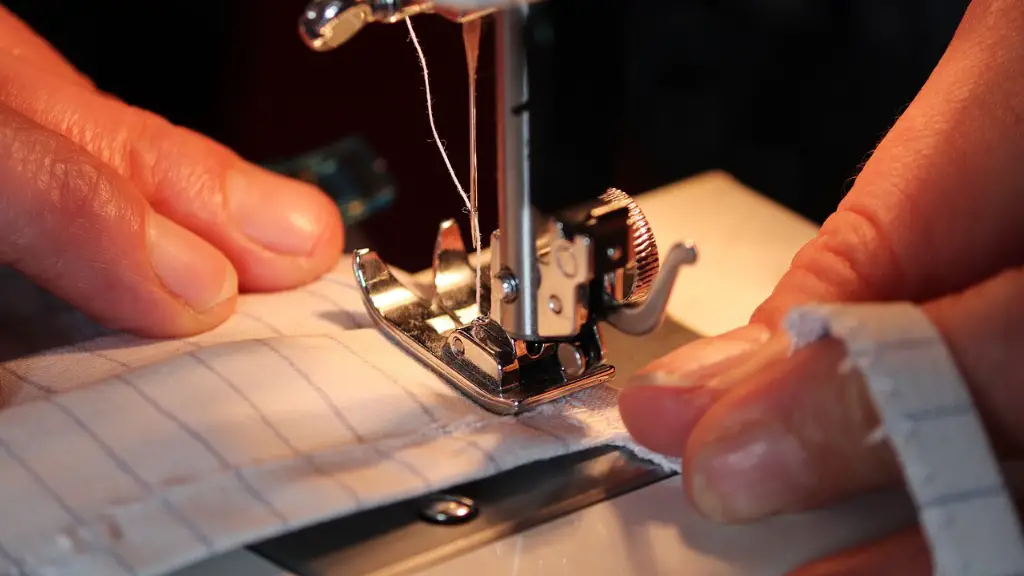

To change an industrial sewing machine needle, first unscrew the needle plate with a screwdriver. Be careful not to drop the screw, as it is small and can be easily lost. Next, use a pair of needle nose pliers to remove the old needle by gently grasping it near the eye and pulling it straight out. To insert the new needle, first thread it through the needle plate and then use the needle nose pliers to push it up until the shaft is level with the top of the plate. Finally, screw the needle plate back on and tighten it securely.

How do you remove a needle from an industrial machine?

If you insert a screwdriver into the hole and turn it towards you, you will loosen the needle and the more you turn it, the more the needle will loosen.

This is to ensure that your needle doesn’t get too dull and that your stitches remain consistent. If you notice your needle starting to skip stitches or your thread breaking more frequently, it’s probably time for a new needle.

How do you change the needle on a Juki industrial sewing machine

So you just lift that up there’s a little screw Black screw right here I’m just gonna slide my knife underneath and it should just pop right off be careful not to lose that spring okay so now that we have that off we can see this is your cartridge this is what holds all your toner in here and then this right here is your drum and this is what actually hits the paper and it’s what gets all the toner on there so you want to be really careful with this so you don’t damage it

If you refer to Figure 1, you will note that a needle will have a long thread groove down one side. There is usually a short groove and a scarf located on the opposite side of the needle. The short groove/scarf side of the needle always faces the hook.

How do you remove a thread from an industrial sewing machine?

Okay you see how once you take the finger out it moves very easily Okay when the thread stuck it

More

Okay you see how once you take the finger out it moves very easily. Okay when the thread stuck it

There’s a screw up here on the top that needs to be unscrewed in order to access the needle. Once you have better access to the needle, you can proceed with your work.

How do you know if your sewing needle is worn out?

Needles are the most important part of the sewing machine. Without good quality needles, the sewing machine will not work correctly and the sewing project will be spoiled. Skipped stitches, puckered fabrics and uneven threads are all signs that the needle is damaged or worn and needs to be replaced. Always use the correct type and size of needle for the fabric and thread you are using.

It is important to keep your machine well-oiled in order to keep it running smoothly. You should oil all points of your machine using a drop of oil on every point per every 100,000 stitches for new machines and one drop per 200,000 for general maintenance. This will help to keep your machine running smoothly and prevent issues down the road.

Is it worth buying an industrial sewing machine

Industrial sewing machines are designed for high output and durability, making them a great choice for those who sew frequently. If you’re just starting out, don’t be discouraged by the many settings and options – many industrial machines come with comfortable settings for beginners. With a little practice, you’ll be able to sew like a pro in no time!

If you’re having trouble with your needle, one possible solution is to loosen the school screw. To do this, turn the screw to the left.

How do you change an industrial Overlock needle?

To change the needle on your sewing machine, you will need an allen key. Inside the machine, there are little grub screws that hold the needle in place. Loosen the screws and remove the old needle. Insert the new needle into the machine and tighten the screws.

The hook system on a sewing machine is key to how the machine works. This is the part of the machine that catches the thread as it is forced out of the needle to create a stitch. There are two main types of hooks, rotary and oscillating. Rotary hooks rotate in a circle and are powered by a separate motor from the sewing machine. Oscillating hooks move back and forth and are powered by the sewing machine’s main motor.

What is the correct way to insert a needle

Be sure to sterilize the area around the injection site before proceeding. Swab the area with an alcohol pad and let it dry. Hold the syringe in your dominant hand. With your other hand, gently pinch up the skin around the injection site. Insert the needle at a 45- to 90-degree angle. Once the needle is in, let go of the skin.

The following is a note on the topic of “The flat side of the needle should be facing toward the back of the machine”:

Make sure the flat side of the needle is facing toward the back of the machine. Be sure to insert the needle all the way into the needle clamp, then tighten the needle clamp screw securely.

Which way does flat side of needle go?

A sewing machine needle may look simple, but it actually has several different parts. The shank is the part that fits into your sewing machine; the flat side usually faces the back of the machine, while the rounded side faces the front. The eye is the hole in the needle through which the thread passes; the point is the sharp end that pierces the fabric. The scarf is an indented area near the eye that helps prevent the thread from slipping off the needle, and the groove is a small channel near the scarf that also helps keep the thread in place. Understanding the different parts of a sewing machine needle can help you choose the right needle for your project and ensure that it is properly seated in your machine.

This is a great way to get the thread to the front! We’ll definitely want to pass this from underneath, up and over four times. Thanks for the suggestion!

Warp Up

1. Turn off the power to the sewing machine.

2. Raise the needle to its highest position by turning the handwheel towards you.

3. loosen the needle clamp screw and remove the old needle.

4. Insert the new needle into the needle clamp with the flat side of the needle facing the back of the machine.

5. Tighten the needle clamp screw and lower the needle into the needle clamp.

6. Turn on the power to the sewing machine and test the new needle by sewing a few stitches.

After some trial and error, you should be able to figure out how to change the industrial sewing machine needle. Make sure to consult your user manual for specific instructions on your model. With a little patience, you’ll be back to sewing in no time!