Part 1: How to Change Needle in Brother Sewing Machine

Changing a needle is a necessary but simple task for many different types of sewing machines. Depending on the type of machine, changing needles might be slightly different, but the same basic steps are applicable for all.

When replacing needles on Brother sewing machines, it is important to first note the type of needle the machine uses. Types of needles vary from machine to machine and can be determined by the seller or manual that came with it. Most Brother sewing machines use either a 15×1, 16×5, or 20×7 needle size.

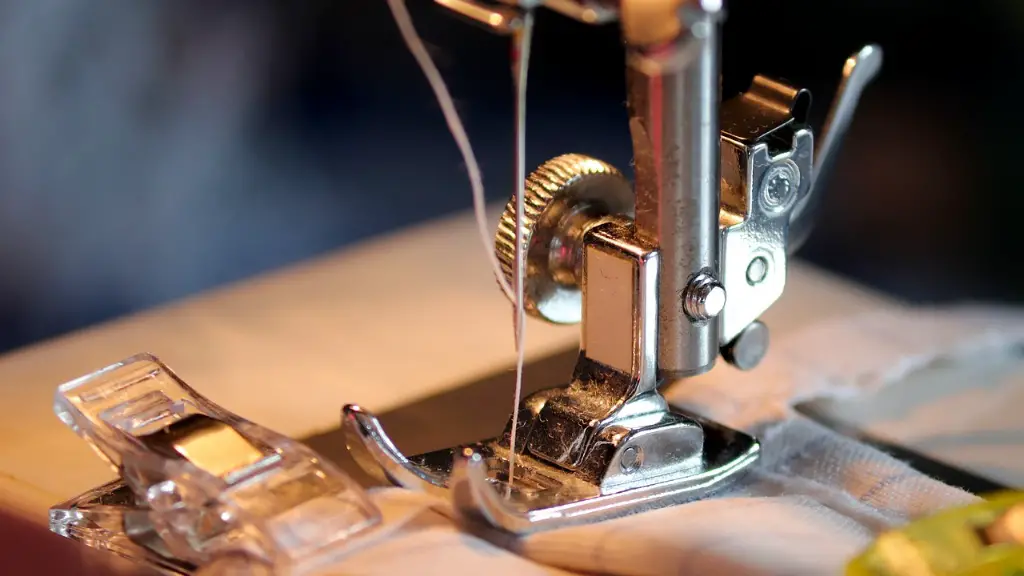

To change the needle in a Brother sewing machine, begin by turning off the machine and unplugging it. Next, slide the needle clamp screw toward the front of the machine. Then, raise the needle to its highest position by turning the knurled wheel and pulling the needle in the upward direction. After this, remove the old needle by grasping it in the center, and pulling it out. Make sure to note the direction the old needle is facing because it will have to be inserted in the same way.

Take the new needle and make sure it is the same size as the old one. If it is not, do not attempt to use it. Insert the new needle into the needle bar from the front, making sure that the flat side of the needle is facing the back of the machine. To ensure a snug fit, move the needle up and down a few times, and then push it all the way up until the needle is hand-tight.

Finally, hold the screw firmly, slide it towards the back of the machine and tighten it firmly but not too much. To check if the needle is inserted correctly, turn the wheel and lower the needle and check if it looks in line with the fabric plate. If it is, you are ready to start sewing again with your newly inserted needle.

Part 2: How to Choose and Buy Needles

Choosing the right needle for a sewing machine is an important part of the sewing process. Whether it is for hand sewing or for a machine, the needle has to fit correctly into the fabric or the material being sewn. Different sizes and types of needles work best with different types of fabrics.

Needles come in different sizes, such as 15×1 and 16×5, and they also have different points, such as sharp, ballpoint, and universal. A needle’s point describes its end shape. When it comes to buying needles, it is important to note the type of fabric that the needle is intended for. Different fabrics, such as denim, knit, or leather, require different needle types. It is also important to note the type of stitch being used as some machines can only work with certain needle types.

When buying needles, it is important to consider quality as a needle’s sharpness and strength can affect the sewing process. Many brands offer high-quality needles that last longer than others. While it is generally less expensive to buy a cheap needle, the quality can vary and the results may not be as good. It is generally best to invest in high-quality needles for best results.

When buying needles, it is also important to buy from a trusted source. Many stores and online shops sell needles, but it is important to research the store beforehand to ensure that it is a trusted seller.

Part 3: What to Look for When Buying a Needle

When buying a needle, it is important to look for a few key characteristics that can help ensure a successful sewing experience. The most important factor will be the size and type of the needle, as this will indicate which fabrics it can be used with. As mentioned before, different fabric types require different needle types.

Another important feature to look for is the quality of the needle. As mentioned, high-quality needles are generally more expensive but last longer and result in better-looking stitches. Additionally, higher-quality needles may also be sturdier and easier to thread. When buying needles, it is important to look for both the size and quality.

It is also important to look for a needle that fits the specific type of machine that you own. Many popular brands like Brother and Singer offer their own line of needles that are specifically designed to fit their machines. While it is possible to use generic needles with the machine, it is generally better to stick with the brand’s own needles.

When buying a needle, it is also important to consider the threads that the needle can use. Generally, needles are either compatible with polyester threads or poly-cotton threads. It is important to note the type of threads the machine will be using before purchasing the needle.

Part 4: Types of Needles Used in Brother Sewing Machines

Brother sewing machines use three main types of needles: 15×1, 16×5, and 20×7. 15×1 needles are a universal needle size and can be used for general sewing purposes. 16×5 needles are slightly larger needles used for heavier fabrics and for thicker thread weights. 20×7 needles are larger needles used for sewing thicker fabrics, such as leather.

Within each size, there are also different types of points. Brother machines typically use a sharp point needle, which is designed for use with woven fabrics. Needles with a ballpoint tip are designed for use with knit fabrics. Finally, universal needles are designed for use with both woven and knit fabrics.

When choosing a needle type for a Brother machine, it is important to consider the type of fabric and thread being used. For general purpose sewing, a 15×1 universal needle with a sharp point should be sufficient. For heavier fabrics and thicker threads, a 16×5 or 20×7 needle may be required, depending on the fabric and thread weight.

Part 5: Needles and Thread

When it comes to sewing, needles and thread go hand in hand. Finding the right combination of thread and needle for a particular project is essential for achieving the desired results. Generally, the needle size should correspond to the thread size.

For Brother sewing machines, a 15×1 needle should generally be used with a standard size thread, while a larger needle, such as a 16×5 or 20×7 may require a thicker thread. Additionally, a heavier thread may require a larger needle in order to accommodate it. It is important to take these considerations into account when choosing a needle and thread combination.

When choosing thread and needles, it is also important to consider the type of fabric being used. Different fabrics require different types of needles and threads. For example, knit fabric may require a ballpoint needle and a poly-cotton thread, while heavier fabrics, such as denim or canvas may require a larger needle and a polyester thread.

When choosing a thread and needle combination, it is important to experiment with different types and sizes until a satisfactory result is achieved. Testing different threads and needles on scrap fabric can help in determining which combination will work best for a particular project.

Part 6: When to Replace the Needle

Needles for sewing machines should generally be replaced after about 8 to 10 hours of use. This is to ensure that the needle remains sharp and to prevent the needle from damaging the fabric or the machine. Over time, needles can become dull and cause irregular and unprofessional-looking stitches.

It is important to inspect the needle often to check for signs of wear. If the needle becomes bent or dull, it should be replaced immediately. Additionally, if the needle has an excessive amount of thread build-up, it can cause the needle to break and should be replaced.

When replacing needles, it is important to make note of the needle size and type being used. This will ensure that any replacement needles are of the same size and type. Additionally, it is important to make sure the needle is properly inserted and that the needle clamp screw is firmly tightened.

Part 7: Caring for Sewing Machines

In order to ensure a successful and long-lasting sewing experience, it is important to care for and maintain the sewing machine regularly. This includes regularly changing the needle, cleaning the machine, and checking for loose parts or debris.

When caring for Brother sewing machines, it is important to inspect the machine regularly for signs of wear and damage. If any parts are loose, broken, or worn, it is important to replace them right away. Additionally, it is important to clean the machine regularly to prevent any built-up lint or dust. Finally, it is important to check the tension of the thread regularly and to make sure that the thread is properly inserted into the needle.

Caring for a sewing machine properly is essential for a successful and long-lasting sewing experience. Taking the time to inspect and maintain the machine regularly can make all the difference in achieving professional-looking results.