If you’re looking to change the needle on your industrial sewing machine, there are a few things you’ll need to keep in mind. First, you’ll need to choose the right needle for your project. There are a variety of needle sizes and types available, so be sure to consult your sewing machine’s manual or a professional before making your purchase. Once you have the right needle, you’ll need to thread it properly. Again, consult your machine’s manual for specific instructions. With the needle threaded, you can then start sewing!

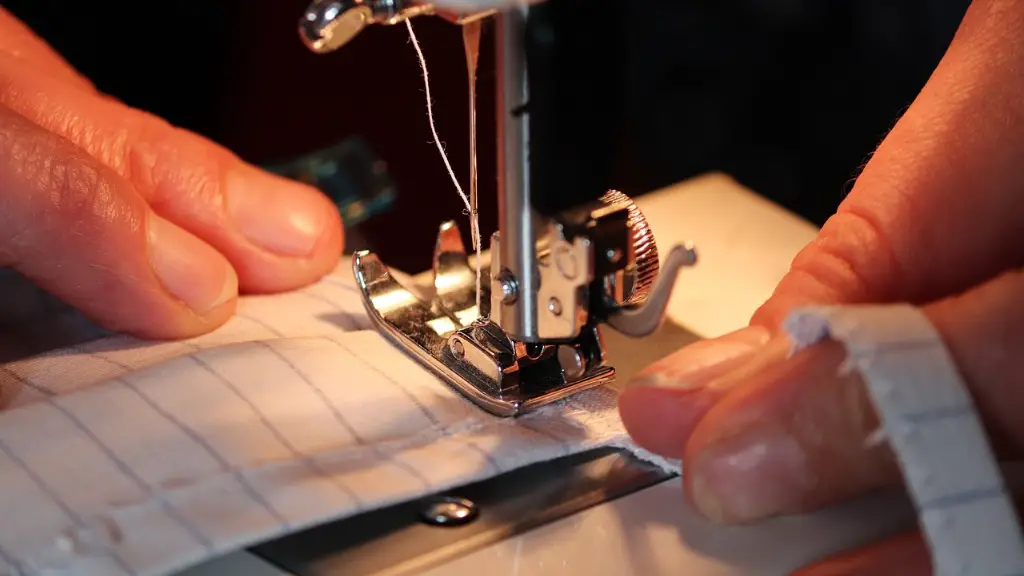

To change the needle in an industrial sewing machine, first ensure that the machine is unplugged. Next, locate the needle clamp screw and loosen it using a screwdriver. Then, remove the old needle by gently pulling it out. To insert the new needle, simply insert it into the needle clamp until it is secure. Finally, tighten the needle clamp screw and re-plug in the machine.

How do you change the needle on a Juki industrial sewing machine?

So you just lift that up there’s a little screw Black screw right here I’m just gonna slide my screwdriver in there and loosen it up and then we can just pull that off and that will give us access to the wires right here so we can just twist them off and then we can put our new one on so

This is to ensure that your needle stays sharp and doesn’t become dull, which can damage your fabric.

How do you change a needle on a sewing machine

There are two parts to a needle – the flat part and the round part. The flat part is called the shaft and the round part is called the eye.

This is how you loosen the school screw on a sewing machine. This is important to do before you start sewing.

How do you change an industrial Overlock needle?

To change the needle on your sewing machine, you will need an allen key. Inside the machine, there are little grub screws that hold the needle in place. loosen these screws and remove the old needle. Then, insert the new needle into the machine and tighten the grub screws.

If you’re experiencing any of the above issues with your sewing machine, it’s likely that your needle is damaged or worn out. Replacing your needle is an easy and affordable fix that can make all the difference in your sewing projects.

How often should I oil my industrial sewing machine?

You should oil your machine at all points using a drop of oil on every point per every 100,000 stitches for new machines and one drop per 200,000 for general maintenance. This will help to keep your machine running smoothly and prevent any rust or wear and tear from occurring.

If you’re using your machine a lot, you probably need an industrial sewing machine. Don’t let intimidation get the better of you. Many newer industrial sewing machines come with many settings that are comfortable for beginners too.

How do I change to a different needle

Size

Let me show you how I do that. You just work right in to that first live stitch, sliding it over to the needle as you go. Then, when you have a few stitches on the needle, you can start working them off.

Needle pliers are a type of medical equipment used to remove needles from the body. They are typically made of metal and have two jaws that grip the needle. To remove the needle, the user must either unscrew the needle or pull it off. Once the needle is removed, it must be discarded immediately into a sharps container.

How do you change a stylus needle?

Step 4: read the instructions for the new needle if it came with none, simply insert it into the needle cap and screw it on. If your machine came with a needle installation tool, follow the manufacturer’s instructions for using it.

To remove the needle from the machine, simply unscrew it and it will come right out.

How do you remove a thread from an industrial sewing machine

Okay, you see how once you take the finger out it moves very easily. Okay, when the thread is stuck it is because the string is wrapped around the axle too tight. Just take a scissors and cut the string.

If you have a needle that has fallen into your machine, don’t worry! Here’s how to remove it:

1. Turn the machine off

2. Remove the presser foot and presser foot holder

3. Remove the needle plate cover

4. Remove the bobbin case

5. Remove the needle plate using the included disc-shaped screwdriver to loosen the two screws on the needle plate.

And that’s it! Now you can reassemble your machine and get back to sewing.

What is an overlock needle?

If you’re looking for a needle that can penetrate the fabric threads of woven fabrics, then you’ll need a Serger/Overlock Machine Needle. These needles come in a variety of sizes and styles, so you can find the perfect one for your project. Ball Point (Style 2054-06) serger needles are perfect for sewing on knits; the rounded tip allows the needle to pass between the fabric threads by dividing the hem.

Please ensure that you:

– Pull the needle downwards

– Off reinsert a new needle

– Push upwards until the top of the needle is level with the top of the syringe

Warp Up

To change the needle in an industrial sewing machine, first locate the needle clamp screw and loosen it. Next, insert the new needle into the needle bar so that the flat side of the needle is facing the back of the machine. Finally, tighten the needle clamp screw to secure the needle in place.

There is no one-size-fits-all answer to this question, as the best way to change a needle on an industrial sewing machine may vary depending on the machine’s make and model. However, there are some general tips that can help make the process go more smoothly. First, be sure to consult your machine’s manual to find out what type and size of needle is recommended. Once you have the correct needle, insert it into the machine’s needle bar, making sure that the flat side of the needle is facing the right direction. Finally, use the machine’s handwheel to lower the needle into the fabric, being careful not to force it.