Sewing is a skill that is not just for experienced seamstresses and tailors, but for everyday hobbyists and fashion enthusiasts alike. Though it can be intimidating to get started, the process of changing a Brother sewing machine needle position is simple when broken down into a few basic steps. To accurately and safely complete this task, make sure to gather necessary tools and familiarize yourself with the machine beforehand.

The tools needed to successfully change the needle position are usually included with the machine when you purchase it. Generally, these tools include a screwdriver, oil, a brush and a needle clamp. If any of these items are missing or worn out, you should purchase a new set to avoid any potential sewing machine damage. Once you’ve successfully gathered all the necessary materials, it’s time to begin the process of changing the needle!

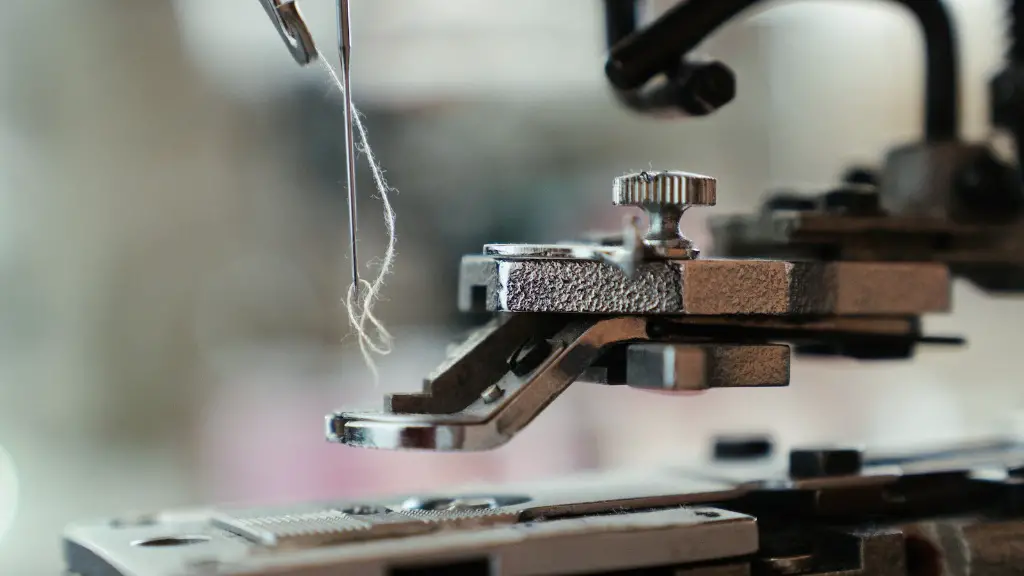

The first step is to turn the power off. Safety should always be prioritized when working with sewing machines, and Brothers in particular. Turning the power off will prevent any safety risks. Removing the needle is the next step. To do this, gently loosen the screw with the screwdriver until it comes undone. Make sure to keep the screw in a safe place and make sure not to touch the metal parts of the sewing machine.

Threading the new needle is the next step in the process. With the new needle securely in hand, slide it into the needle clamp until it is firmly fastened. Be sure that the needle is pointing up and that the flat side is facing the rear of the sewing machine. Check the needle size with the user’s manual to ensure the needle is the correct size for your Brother sewing machine.

Next, raise the needle arm to its highest position and make sure the retainer lever is in the correct stance. Double check that the needle is properly in line with the stitching lines before lowering the needle bar. And lastly, tighten the screw on the needle’s tip with a screwdriver to complete the process.

Advice from Experienced Sewers

When it comes to sewing machine needles, experienced machinists often suggest using quality, brand-name needles and to always check the needle size and needle position to ensure the best results. Additionally, if it is ever hard for the screwdriver to turn or the screw to loosen, put a drop of oil onto the threads to loosen it. Make sure to keep the machine and machine tools clean, as broken needles or lotions can cause unexpected issues.

Practicing Before Using

Prior to changing the needle on a Brother sewing machine, experts often advise doing a few practice runs to get comfortable with the process. Place several pieces of scrap fabric beneath the machine and feed the fabric through using the correct needle size. This way, you can build up confidence and become familiar with the machine’s operations at a slow, comfortable pace. Afterward, you’ll be ready to successfully change the needle without any problems.

Maintenance Tips and Tricks

Maintaining a Brother sewing machine is important. Checking the needle and thread mechanism should be done every time you use the machine, as well as before and after each project. Additionally, move the needle up and down to observe if the machine is functioning properly, and if it’s not, oil it and check the needle size. Also, make sure to unplug the machine when it’s not in use to practice safe sewing tactics, and refer to the instruction manual for trouble-shooting and periodic maintenance.

Things to Keep in Mind

Changing the needle position on a Brother sewing machine can take some getting used to, as every machine is different. However, with a few tips and tricks, you can learn how to do it safely and efficiently. Don’t rush into a project and make sure all necessary tools are in hand: a screwdriver, oil, a brush and a needle clamp for starters. Additionally, do a few practice runs before you actually use the machine, and don’t forget to unplug the machine when it’s not in use. If all else fails, consult the user manual.

Tips for Different Situations

Depending on your level of experience and the specific machine you’re using, the process of changing the needle position on a Brother sewing machine can vary. For more experienced sewers, the steps are often shorter, as they can usually change a needle without needing to refer to the user manual. On the other hand, newer users may need to take the process more slowly and reference the instruction manual.

Spare Parts Availability

The majority of spare parts and accessories used in Brother sewing machines, such as needles and thread, can easily be found in fabric stores or online. Having an adequate supply of needles available when changing the needle on a Brother sewing machine helps ensure that you won’t run into any issues when you need to change it again. Buying spare parts and tools from trusted retailers also ensures that you’ll have quality products that will last throughout all projects.

Preventative Care

It’s important to practice preventative care for Brother sewing machines, including paying attention to common issues, such as tension and stitch length. Investing in a quality machine oil will help keep the sewing machine in good condition and prolong its life. Regularly checking the needle, thread mechanism and needle size is also key to keeping it functioning properly for longer. Additionally, always have spare parts and accessories on hand, as well as a user’s manual in case you encounter any unexpected issues.

Conclusion

Changing the needle position on a Brothers sewing machine is a fast and easy process that usually takes only a few simple steps. However, it’s important to understand the basics, prepare beforehand, and practice preventative care when working with a Brother sewing machine. With the right knowledge and supplies, changing the needle position will be a breeze!