Hooking the Bobbin to the Machine

Learning how to change a bobbin on a Singer sewing machine is an important step to mastering the craft of sewing. Depending on the model you have, you may have to make a few minor adjustments here and there, but hooking a bobbin to the machine is a process that remains largely similar among machines. This article will provide a step-by-step guide on how to hook the bobbin to a Singer sewing machine.

First and foremost, remember to unplug your machine when replacing the bobbin. This eliminates the risk of getting electrocuted from the machine being on a live electrical circuit. Additionally, some machines require a screwdriver to open the bobbin compartment. If you’re working with one of these types of machines, make sure to have a screwdriver at your disposal.

Having done that, lift the darning plate where you’ll find the bobbin housing opening. John, a Singer sewing expert, claims that failure to lift the darning plate before attempting to replace the thread bobbin will prove to be challenging. “In most cases, you’ll find that the thread bobbin can be easily accessed if you just lift the darning plate off the throat plate of the machine.”

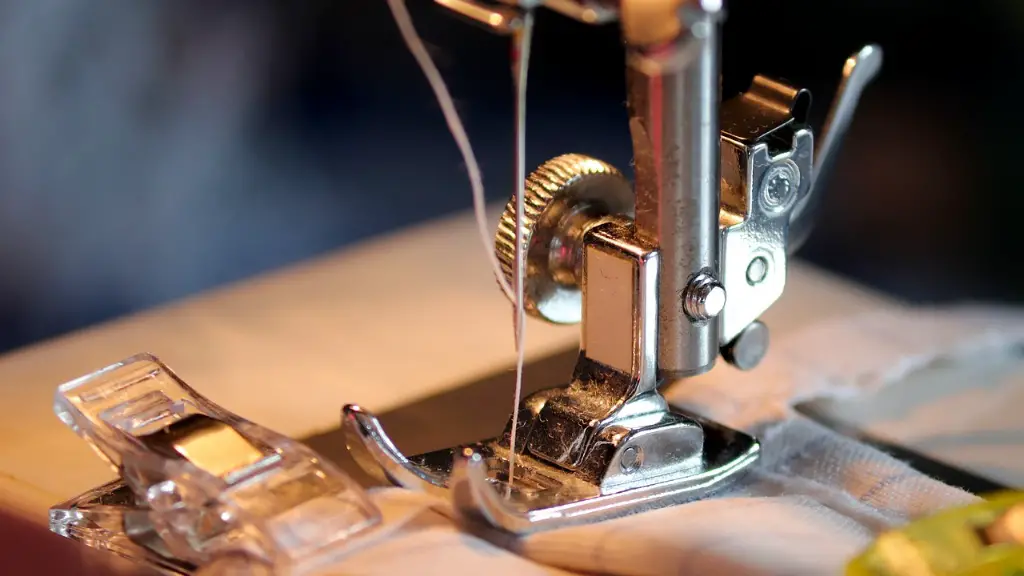

The throat plate is the part of the sewing machine on which the needle passes through to carry the thread up and down. Meanwhile, the bobbin housing typically has a slot where you can easily slide the bobbin into place.

Take the bobbin and wind the thread round it in a clockwise direction. See to it that the thread loops around the neck of the bobbin and not the side. Once you have wound the thread around the bobbin, insert it into the bobbin holder with the thread trailing behind it. Then, close the bobbin housing using your screwdriver if necessary and replace the darning plate.

Preparing the Threading Plate

The next step is to prepare the threading plate. Doing this will help to pass the thread around the bobbin holder before the bobbin takes on the shape of a loop. Start by putting the spool of thread in its designated place. For example, some machines have a clip at the top that helps to hold the spool in place.

Once the spool is secure, take the end of the thread and draw it back over the top and the front of the machine. Reach the needle and pull the thread under the thread guide located near the needle. To do this, you’ll need to drop the needle and guide the thread from the back of the machine to the front.

At the same time, gently tug the thread until it passes through the tension discs. Note that your sewing machine must be switched off at this point. “Don’t attempt to route the thread via the tension discs when it is on,” John Adds.

Finding the Take Up lever

Having done that, identify the take up lever on the machine. Pull it to the highest position once you’ve identified it. This will enable the thread to pass through the take up lever or thread guide slot. Thereafter, draw the thread down the lower thread guide above the bobbin holder.

From there, lead the thread up to the winding post. Then, route the thread over and around the winding post in a clockwise direction. Pull it towards the back of the machine and reach over the bobbin holder.

Once the thread is slightly taut, press the needle plate down with your finger to secure the bobbin holder in place. Thereafter, press the spool pin to allow the take up lever connects with the bobbin in the holder. This will cause the bobbin to spin in a counterclockwise direction.

Adjusting the Tension

Karen, another singer sewing expert, suggests that you need to adjust the tension once you’re done. “This is to ensure that the bobbin thread is not too loose or too tight. The goal is to ensure that the two stitching threads combine comfortably at the back of the needle plate.”

To do this, loosen the tension of the upper thread by turning the tension knob without reaching the tension discs. Turning the knob to the right should loosen the thread tension. Then, take a test stitch and assess the tightness of the lower thread.

You may have to adjust the tension a few times to get it right. To do this, turn the tension knob to the left to increase the tension. Remember to be gentle with the adjustments to avoid damaging the tension discs.

Raise the Take Up Lever

Once you have adjusted the thread tensions, raise the take up lever back to its highest point. This will allow you to follow the thread from the spool pin to the needle. Thereafter, lead the thread from the needle back down the thread guide and reel it off the bobbing. The goal is to create a loop of thread beneath the bobbin casing.

Then, draw the thread under the foot and to the back of the machine. Ensure that the thread is not twisted when making your way around the machine. From the backside, draw the thread around the small guide channel and towards the bottom of the stitch regulator.

Start Sewing

After that, draw the thread behind the guide of the bobbin. Then, lead the thread to the front of the machine, draw it behind the needle plate and around the thread guide. Once you’re done, pull the thread out at the front of the machine.

At this point, you can turn your machine on and start sewing. The goal is to ensure that you have your two stitching threads evenly wound around the bobbin holder’s guide. If everything goes as planned, you should be able to hold the thread from both the spool and the bobbin and pull them away from the needle in opposite directions.

Change Your Upper Thread

While you may have successfully replaced the bobbin, you should still be prepared to change the upper thread if it is running low. To do this, make sure that the darning plate is up and drop the needle as before. Taking hold of the end of the upper thread, move it behind the thread guide and pass it through the tension discs.

Once that’s done, wind the end of the thread around the spool pin and move the spool over to the holder using a slight shift in the spool holder mechanism. Lastly, draw the thread under the thread guide and from the bottom thread guide to the needle.

Check Your Bobbin Thread

Now it’s time to inspect the bobbin for excess thread. All you need to do is to turn the handwheel to ensure that the thread does not get twisted. After a few pulls from the handwheel, you should be able to spot the bobbin thread coming from the needle.

If there’s a lot of loose thread above the needle, take it out by cutting it away with scissors. This will prevent the thread from finding its way into the feed dogs or becoming twisted around the needle plate. Subsequently, you’ll have successfully replaced the bobbin on your Singer sewing machine.

Practice, Practice, Practice

For those who are just getting started with a Singer sewing machine, remember that it takes time to master the art of replacing a bobbin. Such processes require a bit of practice, so don’t be discouraged if your first few attempts fail. Keep trying and you’ll eventually get the hang of it.

In addition, don’t be afraid to take your machine to an expert for a tune-up or for further guidance. Most sewing experts are more than happy to assist novice sewers, as sewing is a craft that requires a lot of patience.

Shop for High-Quality Bobbins

If you want an uninterrupted sewing experience, consider investing in high-quality bobbins for your Singer sewing machine. After all, it’s only natural that replenishing one’s supply of bobbins occurs quite frequently.

Needless to say, the basics of what constitutes a good bobbin remains largely uniform. Such elements include resistance to wear and tear, a good finish, compatibility with the singer machine, and ease of tension adjustments. It is advisable to purchase the bobbins from verified sellers and also take time to inspect the bobbins before you purchase them.

Which Bobbins Fit Which Machines?

For those looking to purchase Singer bobbins, there’s one rule of thumb that you should always keep in mind: different Singer models use different bobbin sizes. It follows that Singer Touch & Sew models use 15-class bobbins while the Stylist Models use model 20 class bobbins. Similarly, Singer Quantum models use 20-class bobbins, and Heavy Duty models of Singer use 30-class bobbins.

In other words, ensure that you get the right bobbin for your sewing machine model. That way, your sewing experience will be smooth and uninterrupted.

Types of Bobbins

In addition to selecting the correct Singer bobbin for your machine model, there are several other types of bobbins that you should be aware of. Reeled bobbins are the most common for high-speed machines. They are typically round, cylindrical, or slightly conical and have a hole in the center.

Flangeless bobbins, on the other hand, are flatter than reeled bobbins, which makes them better-suited for machines that run at low speeds. Additionally, there are also hank-style bobbins which are commonly used on shuttle-hook machines. Such bobbin types typically have a flange and are made of wood or plastic.

Finally, side tension bobbins are a type of bobbin that provides more precision in terms of adjusting the thread tensions. Such bobbins are also more durable than other bobbin types and tend to last an extended period of time before needing a replacement.

Important Safety Tips

Before attempting to change a bobbin on a Singer sewing machine, it is essential to keep your finger from getting stuck in the machine. This is especially important when you’re resetting the bobbin, as the needle rotates at high speeds. As such, it is best to unplug the machine and turn it off before attempting to reset.

Another safety tip is to ensure that the machine is properly lubricated before use. Oil lubricants are typically used to ensure that parts of the machine don’t get scratched or worn down due to friction.

It is also important to make sure that you don’t force the bobbin when threading it. Such actions can lead to damaged parts and may even render the machine unusable. It is therefore important to take as much care as possible when resetting the bobbin.