Singer sewing machines have been a popular and trusted choice for generations, but with age and use, these machines can start to show the tell-tale signs of wear and tear. Without proper cleaning, it is easy for the efficiency of a Singer sewing machine to be impacted, and neglected machines can even become unusable over time. While it can be a time consuming job, cleaning an old Singer sewing machine is essential in order to protect the valuable investment you made in your machine.

The first step in cleaning a Singer sewing machine is to clear away any lint or dust that may have accumulated. The best way to do this is to use an air compressor or a vacuum cleaner to suck out the debris. If using a vacuum cleaner, make sure the vacuum has a soft brush attachment, as anything too abrasive could cause damage to the inner components of the machine. Once this is done, you should also use a soft damp cloth to wipe away any stubborn particles that are difficult to remove with the vacuum.

The next step is to check for any visible signs of wear and tear. This includes looking for worn belts or parts that look cracked or bent. If any parts need to be replaced, it is important to have them done professionally as attempting to do so yourself can irreversibly damage the machine.

Once the surface has been checked it is essential to oil all moving parts with a specialist sewing machine oil. This should be done liberally but careful to not over-oil as excess oil can seep into some of the parts and could cause the machine to become clogged.

Finally, make sure to check the wiring inside the machine for any wear or tear. This is especially important for older Singer sewing machines, as the wiring system may be more vulnerable. If any malfunctions do occur, it is best to have the wiring inspected by a professional.

Lubrication

In order to keep your Singer sewing machine in good working order, regular lubrication is essential. The best type of lubrication for a Singer machine is a light or medium weight machine oil, which should be applied to any moving parts. It is important not to use motor oil or WD-40, as these products can over time, leave a sticky residue on the machine’s parts, which can cause further damage.

It is always a good idea to straighten the shuttle race of your machine, which is the round hole that the shuttle travels through when the machine is running. This can be done with a can of pressurized air, while making sure to keep the can at least six inches away from the machine.

You should also look out for gears and screws that could be coming loose and, as most Singer machines have exposed gears, it is easy to spot any worn parts that need additional lubrication. This is especially important for older machines, as the parts may have become loose and could be in need of tightening.

Cleaning stitches

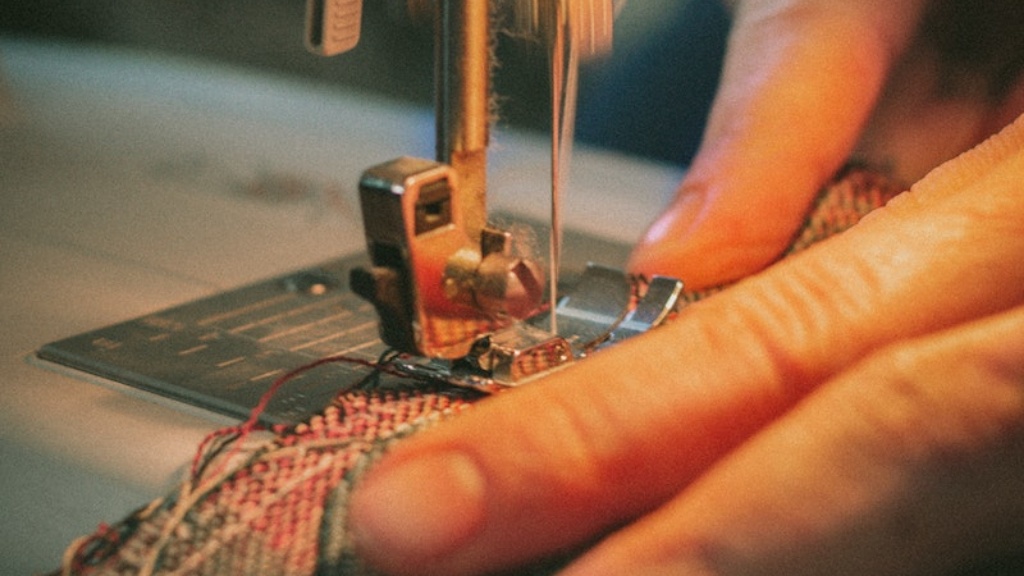

Once the maintenance of your machine is complete, the last step is to clean the stitches. Any residual lint or other deposits should be removed from the fabric being worked on, as this could cause the stitch system to become clogged or blocked. This can be done by using a lint brush or with a damp cloth and a small amount of mild detergent.

Once the lint has been removed, it is a good idea to give the fabric a steam cleaning to really get rid of any residual dirt. This can be done with a steamer, which can be found in any store that sells Singer sewing machines, or by simply running the fabric through a steam iron.

Finally, if you are having trouble getting the stitches to look just right and have been having difficulty with the tension, it is best to have the machine tension checked by a professional. This can be done at the same place where you bought the machine or at any speciality shop that deals with Singer machines.

Storing the machine

When it comes to storing a Singer sewing machine, the best place is inside a case with a handle and a latch. This will keep the machine safe from dust and dirt, as well as protecting the machine from bumps and scratches. Never stack heavy items on top of the machine, as this could cause permanent damage.

It is also essential to keep the machine away from direct heat, as this can cause warping or cracking of the plastic parts. Never store the machine near windows, as too much sunlight can cause the plastic parts to fade over time.

Using the machine

When it comes to actually using a Singer sewing machine, it is important to be gentle as the parts are highly sensitive. Do not force any of the parts as this could cause damage to the machine, and always use the foot pedal slowly and steadily.

It is also important not to work the machine for too long at a time, as the motor can overheat and become damaged. If you are working on a particularly large project, it is best to take regular breaks and to make sure that the machine is well ventilated.

Using the right needles

Additionally, only use machine needles designed for Singer machines, as other needles may not be compatible and can end up causing damage. The wrong type of needle may not be seated correctly, or may be too large and this could cause the needle eye to be blocked or jammed.

Before starting any major project, always test the machine on a piece of scrap fabric first. This will ensure that the machine is working correctly, and can also help to identify any problems that may arise later.

Check for dirt and dust

It is also important to regularly check for dirt and dust inside the machine, as this can cause the motor to overheat and become damaged. To do this, first unplug the machine and carefully remove the screws from the bottom of the machine. This will give you access to the internal components, which should be wiped down with a soft damp cloth.

Once this is done, make sure to check the belt and make sure it is still intact and in working order. If there are any signs of wear and tear, it is best to have it professionally replaced, as doing so yourself could irreversibly damage the machine.

Singer Sewing Machine Care Product

Finally, investing in a specialised Singer sewing machine care product can help to extend the life of your machine. There are plenty of products available on the market that are specifically designed for Singer machines, and these products can help keep the machine in good working order for years to come.

These products are typically marketed as being able to clean, lubricate, and protect the machine’s parts. They can help to protect the machine from dirt and other debris, as well as keeping it well lubricated and running smoothly.

It is also important to make sure that you are using the correct parts when repairing or replacing any components of your Singer sewing machine. Without the correct parts you risk damaging the machine beyond repair, and this could be extremely costly.