How to Deep Clean a Sewing Machine

For novice and experienced embroiderers, sewing machines can be like loyal companions – they make it infinitely easier to whip up projects quickly and beautifully. To ensure top performance, regular maintenance and deep cleanings are needed to keep your machine running smoothly and your projects looking great. Here we will provide step-by-step detailed instructions on how to deep clean a sewing machine, including tips from experts on cleaning, machine care, and troubleshooting.

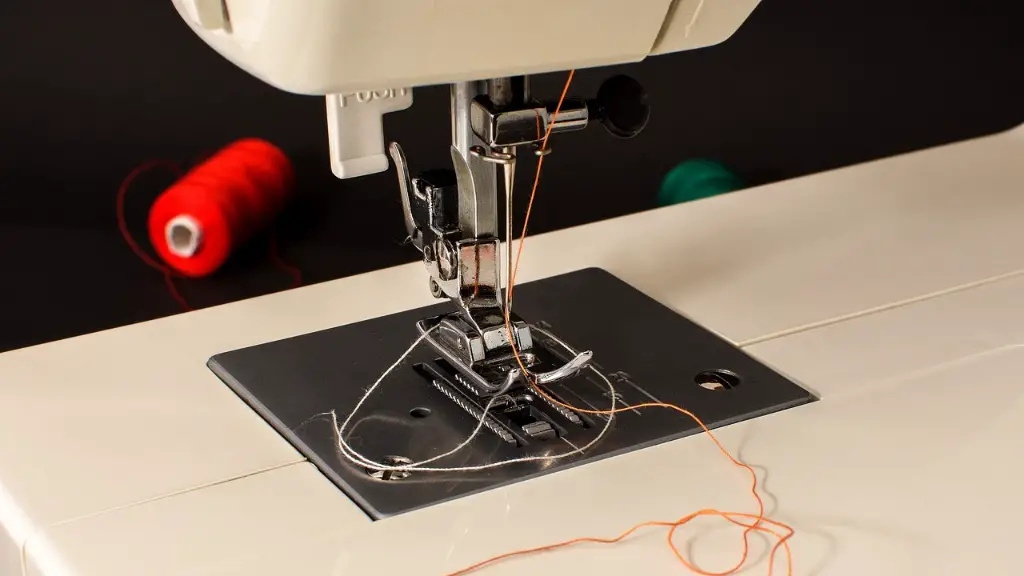

First things first, you must unplug the machine from power source before starting the deep cleaning process. Then, open up both the outside and inside of the machine by removing the side panels, screws, and covers. Vacuum the dust, dirt, and lint inside the machine for about 2-3 minutes to remove any visible dust, dirt, and lint. You should also clean any areas around the needles and threads.

The next step is to use cotton swabs and an adjustable brush to clean out any ridges and crevices inside the machine, as well as the tight spaces between the gears. Make sure to move the brush in a circular motion, and use a gentle disinfectant with alcohol or vinegar to remove any stubborn dirt and debris. Avoid using any harsh chemicals that could damage the wiring or internal mechanisms.

Finally, you will want to lubricate all parts of the machine – this is an important step in the maintenance of your machine. Always use the correct type of lubricant as advised by the manual and ensure that it is safely and evenly distributed. This is a job best left to a technician or expert who knows exactly where to apply it. Once you’ve lubricated the machine, wipe down any excess lubricant using a soft cloth and reassemble the machine.

Regular maintenance of your machine is essential for it to work properly and last a long time. Experts advise that you should clean and oil your machine after every other project, and more importantly, either deep clean or have a professional service technician do a deep cleaning at least twice a year. This will ensure that the machine can keep up with your projects and not create any frustrating problems.

If you are having trouble troubleshooting, there are many resources available that can offer helpful advice. Sewing forums and websites are a great place to discuss issues, ask specific questions, and troubleshoot common problems. This way, you can get immediate feedback from experienced sewers and technical professionals who can provide important tips and tricks for you to get your sewing machine in tip-top shape.

Identifying Problems in Sewing Machines

It is important to identify any possible problems that may arise with your machine, so that you can take the necessary steps to solve them. Common problems with sewing machines include thread tangling, needle sticking, skipping stitches, and fabric bunching. In the event that one of these problems occurs, it is important to first diagnose the issue and then take the appropriate action to fix it.

If the thread is tangling, it is likely due to the tension being set too high or the thread being pulled too tightly. To correct this issue, adjust the tension to the right setting, and follow the threading instructions in the manual carefully. If the needle is sticking, check to make sure that the thread is not too thick or too fine for the needle. If the stitches are skipping, check to make sure that the needle is properly threaded and the tension is set correctly. If the fabric is bunching, check to make sure that the presser foot is properly set.

If you are unable to diagnose the issue and fix it on your own, expert advice is always recommended. Find an experienced technician who can examine and diagnose the machine, as well as provide helpful tips to maintain and fix it. Professional technicians can also provide advice on the types of fabrics, needles, and threads that work best for your particular machine.

Additional Maintenance and Care tips

In order to maintain your sewing machine and ensure that it runs smoothly, expert advice is recommended. Regular maintenance checks should be done to ensure the best performance and longevity. Some of the things to check and maintain include the tension, needle, bobbin, and presser foot.

The tension should be set using the tension dial and then tested on a scrap piece of fabric. If the stitching pattern is forming uneven or tight lines, or the fabric looks wrinkled, the tension may need to be adjusted. The needle should always be replaced with one suitable for the fabric and thread being used.

The bobbin should be regularly cleaned and oiled and replaced frequently to avoid thread jams. The presser foot should also be regularly adjusted as needed. A few drops of oil should also be added to the needle housing and other parts of the sewing machine to keep them running smoothly.

When to Seek Professional Help

If you are unable to diagnose and fix the issue on your own, or if the issue needs more in-depth attention, professional help is always recommended. Experienced technicians and repair professionals can provide advice on the best ways to maintain and repair your sewing machine. Not only can they provide helpful tips and tricks on how to troubleshoot and fix the issue, but they also have access to specialized tools, replacement parts, and other necessary components to service your sewing machine.

Find a reputable sewing machine repair specialist or technician who can provide the necessary services to keep your machine running smoothly. Before making any repairs to the machine, it’s important to do research and read reviews to be sure that you are using a reliable service.

Accessories and Additional Support

Having the right accessories makes all the difference when it comes to sewing machine maintenance and repairs. Anticipate any possible issues by stocking up on thread, needles, bobbins, and other necessary accessories. Additionally, consider investing in an instructional manual and/or instructional DVD to have on hand for quick reference and troubleshooting.

If you require additional support, most sewing machine dealers and manufacturers offer customer service, technical support, and other resources to help troubleshoot issues and answer questions. Additionally, many of these dealers and manufacturers hold sewing classes, workshops and seminars for all skill levels so that you can become more informed and gain more knowledge about the proper maintenance and care of your machine.

Conclusion

Regular maintenance of your sewing machine is essential to keep it running efficiently and ensure that your projects look great. Here we have provided detailed steps on how to deep clean a sewing machine, as well as tips from experts on cleaning and machine care. Additionally, we have discussed identifying and solving machine problems, additional maintenance and care tips, and when to seek professional help. Finally, we have explored accessories, instructional materials, and other support options for an enjoyable sewing experience.