Introduction

When sewing, it is important to have the right size needle for the job. Choosing the right size needle will make the job easier, result in fewer stitches, reduce wear and tear on the fabric, and allow the stitches to sit snugly within the material. This article will explain the different attributes of sewing needles, their importance, and the methods which can be used to determine the size of the needle most suitable for the job.

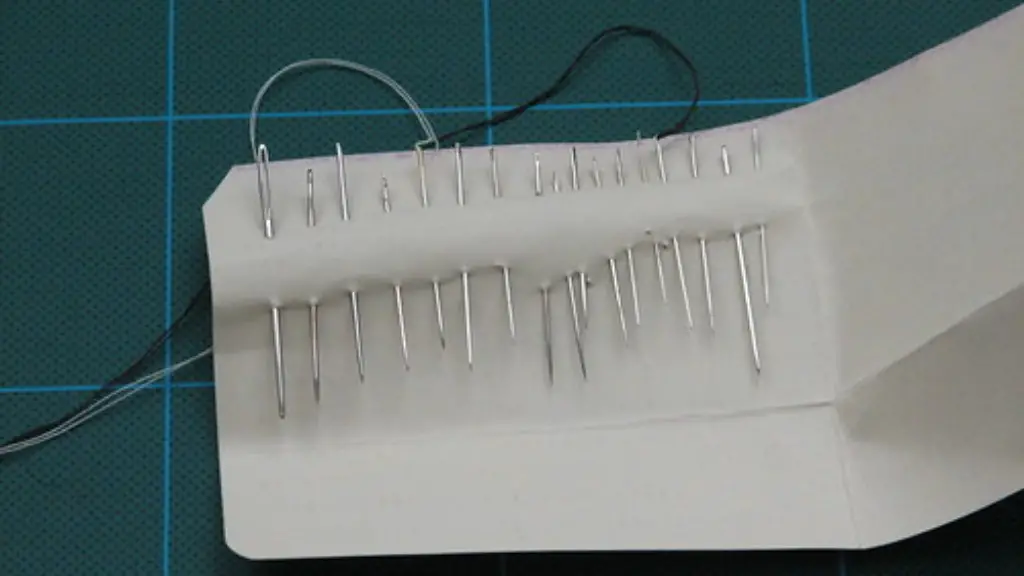

Attributes of the Needle

The size of the needle is measured by its gauge. The needle’s needle gauges can range from 6/0 to 18 and each gauge has a specific size and purpose. The thinner the gauge, the smaller the size and the lighter the material used for the project. It is also important to note that the sizes are inversely proportionate to the numbers; a 6/0 is the thinnest needle and an 18 is the thickest. In terms of types of needles, there are universal needles, ballpoint needles, quilting needles, leather needles, topstitch needles and microtex needles.

Material Determining Needle Size

The material used for the job is one of the main determining factors when selecting the right needle. A light weight material such as muslin will require a thinner, sharper needle such as a 6/0 or 8/0. Medium weight fabrics such as cotton will require a 9/90 needle. Thicker material such as denim or leather needs a thicker needle such as a 14/90 or 16/100.

The Role of Needles

Needles play an important role in the process of sewing. The right needle will allow the stitches to sit flush with the material, ensuring the stitches don’t make holes in the fabric. It will also make the process of sewing easier and reduce wear and tear on the fabric. The needle can also affect the way the thread is correctly distributed, providing a smooth finish.

How To Determine Needle Size

The best way to determine the size of the needle is by referring to the fabric manufacturer’s instructions, which will usually detail the correct needle size for the fabric. If this isn’t available, a good rule to use is the heavier the material, the bigger the needle size.

Testing The Needle

One useful way to determine the size of the needle is to test it on the fabric, although this should be done with caution. Start by sewing a few stitches with the needle and then run the needle through the fabric and pull the thread to see if it slips easily. If the needle slips, this means it is too large and needs to be changed. If the stitches are too loose, the needle may be too small, and needs to be replaced.

Conclusion

In conclusion, choosing the right size needle is vitally important when it comes to sewing. The size of the needle will vary depending on the type and weight of the material being used, so it is essential that the correct size needle is chosen. It is also important to test the needle on the fabric before beginning the project, as this may save time and avoid costly mistakes.

The Role of Threads in Sewing

Threads are an essential part of the sewing process and an important factor to consider when selecting the appropriate needle. Threads come in a variety of sizes and types and can be made from either cotton, polyester or nylon. Each type of thread has its own unique characteristics, such as strength and elasticity, which will affect the overall appearance of the project.

The thread size is usually determined by the weight of the fabric. Lighter fabrics will require a lighter thread, such as 40/2, 50/3, 60/4 or 80/4. Heavier fabrics will require larger threads such as 40/3, 50/4, 60/6 or 80/6. It is important to note that the left side number represents the ply or thickness of the thread, while the right side number represents the number of individual threads twisted together.

The tension of the thread also needs to be taken into consideration. This is determined by the type of thread, the type of fabric and the stitching technique used. For example, a tightly tensioned thread may be suitable for a worktop fabric which requires strong stitching, while a looser tension may be better suited for applique or other styles of decorative stitching.

Needle Tips

When selecting a needle, it is important to choose a needle that is both suitable for the fabric and comfortable to work with. Needles are available in both metallic and non-metallic varieties, and the choice of material should be based on the type of fabric being used. It is also important to note that if the needle is too small for the fabric, it may break or snap easily.

When using the needle, it is best to keep the needle threaded to reduce the risk of breakage and ensure the stitches are uniform and straight. Thread type and composition is also a factor to consider when using the needle, as nylon and polyester threads are more prone to fraying and breakage. It is also worth noting that the thread should be changed every so often to avoid wear and tear on the fabric.

Needle Sharpening

Over time, needles may become dull and no longer suitable for the job. Needles can be sharpened to restore their cutting edge; this is done by running a bead of oil along the length of the needle and then honing or polishing it against a stone. This should be done cautiously, as sharpening a needle too aggressively may destroy its temper and render it useless.

It is important to note that needle sharpening should only be done as a last resort when a needle is no longer suitable for the job. It is also recommended that the same needle be used to avoid any mishaps on the fabric.

Storage and Care

Needles need to be stored and cared for properly in order to ensure they remain in tip top condition. After use, needles should be thoroughly cleaned and dried before being stored in a suitable box. This will help prevent rust, corrosion and breakage. It is also important to note that all needles should be inspected before each use, as a bent needle may cause uneven stitches.

When travelling, it is essential to carry the needles in a suitable container; this helps to keep them safe, prevent accidental needle pricks, and reduce the risk of breakage. It is also important to note that when travelling, the needles should be stored separately from the fabric in order to avoid the risk of snagging or damaging the material.

Needle Safety

Finally, it is important to note that needles should be handled with great care. This includes avoiding contact with the eye area or any other sensitive areas. It is also important to make sure that the needle is free from any debris, as this can result in serious injury. Lastly, it is important to always use a sharp needle as this will reduce the risk of breakage, resulting in a more successful project.