Hand stitches

Hand stitches are the traditional method of finishing a project when sewing. This method of closing a stitch is very reliable and commonly used in clothing and crafts. The method is especially useful when there is a delicate material or an intricate design that needs to be worked on. Hand stitching is often the favoured option when fabrics need more attention than sewing machines are designed to give.

Many people use a running stitch to create a neat finish. This involves using small backward and forward stitches to literally run along the length of the material. Hand stitching does not require a particular type of needle – a universal needle can be used for all fabrics, as long as the tension settings are adjusted. It also does not require as much material to use, making hand stitching a more cost-effective option. You will also find hand stitching to be easier to make precise and accurate, due to the less likelihood of slippage and misalignment when compared to a sewing machine.

Sewing machine stitches

Sewing machines are the primary choice for materials that need to be more durable, such as jeans and other garment materials. Machine stitches offer a stronger and more secure finish, with less chance of fraying and damage. Different sewing machines have different functions, such as zig zag stitches and topstitching, which add further options for creativity and design.

The best way to finish a stitch when using a machine is dependent on the size, type and weight of the fabric. Lighter weight materials should be finished with a backstitch, where the needle goes back over the stitch a few times for a secure finish. Heavier materials, such as denim, should be secured with a triple straight stitch to ensure a strong hold. The length of the stitch should always be checked to ensure the stitch is the correct size, as this can affect the overall strength.

Unlike hand sewing, sewing machines require the user to have the correct size and type of needle, as well as the correct type of thread and tension settings. When finishing a project with a machine, presser feet should be changed as needed and bobbin winder used when winding bobbins. It is also important to ensure the lever is raised after finishing to ensure the needle does not prick the fabric as it moves away.

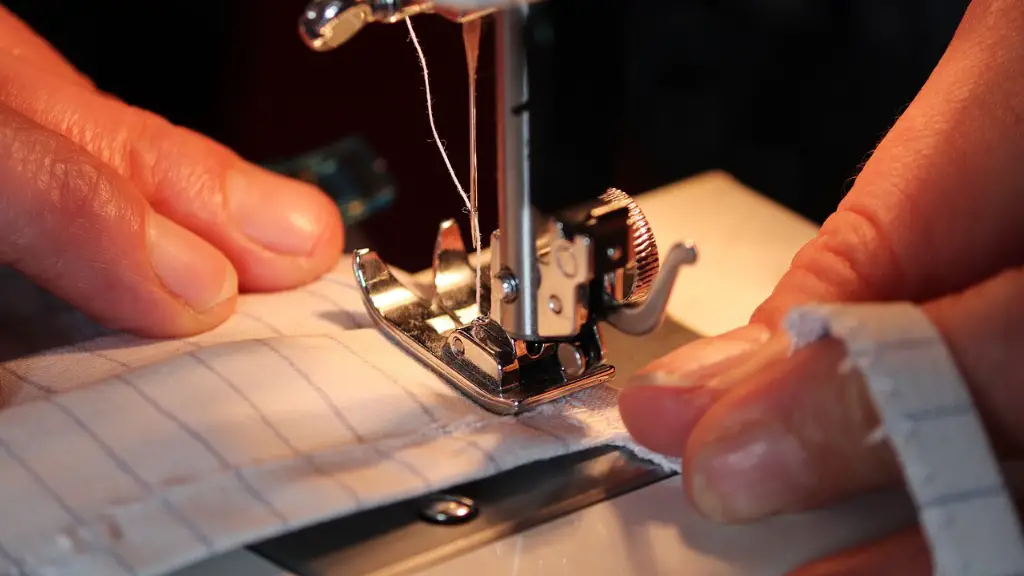

Finishing a stitch on a sewing machine

When finishing a stitch on a sewing machine, it is important to ensure the needle is in good condition and will not snag the fabric or cause any damage. Before beginning a project, it is advisable to check the tension and test the stitch on scrap fabric. If the tension requires further adjustment, this should be done before continuing.

For a neater finish, begin by stitching in reverse for a few stitches before tying off the thread. This will stop the end from being visible from the other side. Once this has been done, the machine should be set back to the forward switch. The next task is to place the fabric back under the presser foot, so that the hook of the needle is aligned with the end of the stitch. The lever should be raised to ensure the needle does not prick the fabric when it moves away.

The last step is to backstitch over the end of the stitch multiple times, depending on the weight and size of the fabric. This adds extra strength and also ensures that the ends of the threads are tucked away and will not unravel. When complete, the thread should be cut and the fabric can be removed from the machine.

Other tips

When finishing a stitch, it is important to check the tension settings throughout the process. It is also important to use the correct presser foot for the type of stitch being used. If a particular stitch requires an invisible seam, an invisible zipper foot or a zig zag presser foot can be used to create a cleaner look.

Always use the correct thread for the fabric being used. Polyester threads are more lightweight and tend to be favoured for lightweight materials such as chiffon, while cotton threads are more suitable for heavier materials, such as twill or denim. For fabrics that are easily damaged, it is best to use a size 14 needle for a finer finish.

When storing fabrics, use beeswax or a silica gel packet to protect it from mildew, climate and heat damage. A good quality tape measure will also be beneficial when measuring out material before beginning.

Tools and accessories

The most important tool when working with a sewing machine is the needle. It is crucial to choose the correct size of needle for the fabric being used. As well as different needles for different fabrics, there are also different types of needles for different techniques. Embroidery needles have large eyes and are designed for stitching with heavier threads, while small-eye sharp needles are suitable for delicate fabrics. For automatic sewing, such as a zig zag stitch, a twin needle should be used.

To ensure the machine runs smooth, the right oil should be used to lubricate the parts. Also, the right type and amount of thread should be used. Thread that is too thick and heavy can cause the machine to struggle and may even break. It is especially important to monitor the bobbin tension, as this directly influences the quality of the stitch.

Maintenance and care

Like most tools, a sewing machine requires regular maintenance and care in order to work correctly. After each use it is important to unplug the machine and remove the bobbin and thread to avoid the machine jamming and clogging up.

It is recommended that the machine be deep cleaned every three months to remove any dirt and debris. If oil is needed, only use sewing machine oil as this will not cause blockages and slippage. Once every year, or after heavy usage, the machine should be taken apart and cleaned and the belt should be checked.

The needle, presser foot and other metal parts will require extra care to ensure they remain corrosion-free, so a metal conditioning spray should be used to clean them. The needles should also be replaced regularly, as they can become blunted and unsuitable. The bobbin should also be checked for smooth operation.

Tips for beginners

Starting to sew can be a daunting prospect, so here are some useful tips for beginners. To begin with, practice the basic stitches on scrap fabric or old clothes. This will help to get a feel of how the machine works and also prepare you for working on bigger, more complicated projects.

Start with some larger, easier projects such as pillowcases and simple clothes and bags to build up confidence and knowledge. Throughout the process, keep notes on any mistakes or issues that occur, so that they can be avoided in the future.

A good way to progress is to follow a tutorial or a pattern. While this can be tricky, it will help develop a plan of attack and an understanding of the step-by-step process. Craft stores, online platforms and books can be helpful in finding patterns and advice.

Taking care of your machine

It is essential to take proper care of your machine to keep it running smoothly. Machines should be kept away from dust, moisture and high temperatures as these can damage the internal components. The inside of the machine should also be vacuumed or wiped out regularly to stop dirt from building up.

Additional accessories such as feet or needles should be properly stored away from the machine and away from direct sunlight. Improper storage can cause parts to corrode or warp, making them ineffective for guiding the fabric.

When transporting the machine, ensure it is turned off and ensure the cords are untangled and unplugged. Avoid carrying the machine by the handles or lifting by the cord – instead, place it in a suitcase or carry bag to minimize the risk of damage.

Safety precautions

Safety should always be the priority when using a sewing machine. To begin with, familiarize yourself with all of the parts of the machine. This will help to quickly identify and deal with any issues that may arise.

When using a machine, always make sure the device is unplugged and the lever is raised before placing or removing fabric. If necessary, use tools such as tweezers or chopsticks to guide the fabric under the needle. Never leave the machine unattended, as this increases the risk of an accident or injury occurring.

Always use the necessary safety precautions when working with a sewing machine. Wear goggles and gloves to protect against needle pokes. If the machine hums when turning it on, but does not move, disconnect it from the power source immediately and get a professional to check it over.