Step By Step Guide

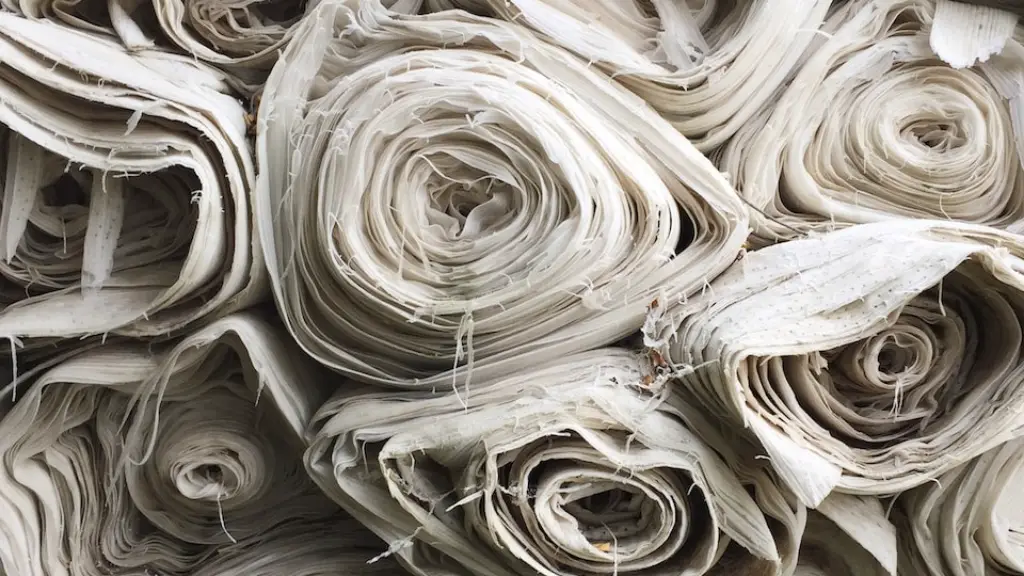

Sewing machines come in all shapes and sizes and each one uses bobbin for threading and winding. While there are different styles of bobbins and bobbin cases, the technique for filling the bobbin is generally the same. Here is a step by step guide to filling a sewing machine bobbin.

1. To begin, choose an open-top bobbin that is compatible with your machine. It is essential to use the correct size and type of bobbin as using an incompatible one may break the machine or cause other issues. If in doubt, consult your sewing machine’s manual.

2. Determine the type of thread you need for your project. The most common kinds used today are made of nylon, cotton, or polyester. It is important to select the thread that gives the proper tension and is compatible with the fabric you are sewing.

3. Measure the thread at the point where it is ready to be loaded onto the bobbin. This is the point where the thread will attach to the spool or cone. You may want to measure 8-10″ for best results.

4. Hold the spool above the bobbin, with the thread spindle closest to the bobbin. This will help ensure secure and even threading.

5. Place the thread on the thread spindle and guide it toward the bobbin. Keep the thread in one hand while threading to maintain tension and ensure the thread wound onto the bobbin is even.

6. For some machines, it’s necessary to hold a finger on the bobbin to ensure it rotates. This will help the thread attach to the bobbin in a secure fashion. For other sewing machines, the bobbin will spin automatically when threading.

7. Continue guiding the thread around the bobbin until it’s full. Generally, when the bobbin is full, the thread will bunch up and become slightly larger. When this happens, all you need to do is remove the bobbin from the thread spindle and the thread will retract.

8. Once the bobbin is full, cut the thread and place it in the bobbin case. If the bobbin case is not full, you may need to add a weight to keep the tension even while sewing.

Securing The Bobbin

Once the bobbin is full and inserted into the bobbin case, it is important to secure the bobbin properly to prevent tangles and other issues. Some machines use a bobbin cover insulator, while others use a latch or a clamp. With a bobbin cover insulator, make sure the bobbin is in place, then snap the cover shut to secure it.

If your machine uses a latch or clamp, fit the bobbin inside and then press firmly to secure it in place. Another option is a plastic clip, which simply clicks onto the bobbin.

Advanced Techniques

For experienced sewists, certain techniques may be employed for a smoother, more efficient bobbin winding process. Some experienced sewists may choose to use an electric bobbin winder to wind the bobbin faster and more efficiently. You may also find an automatic intermediate winding mechanism on some machines, which will wind the bobbin twice as fast as a manual bobbin winder.

Another technique is to use a thicker thread, such as a quilting or heavy-weight thread, to ensure a more secure and even winding. This allows more thread to be wound onto the bobbin, eliminating any gaps and ensuring a more uniform tension.

Additional Considerations

It is important to remember that improper bobbin winding can damage the sewing machine, cause tensioning and threading problems, and hinder the performance of the machine. If you are having any issues with the winding of the bobbin, examine the thread and bobbin case. Make sure the bobbin is inserted correctly into the case and that the thread is properly attached.

If the bobbin case is too tight, it may cause the thread to twist and tangle or impede the machine’s operation. It is important to consult the user manual for specific bobbin winding instructions for your make and model of sewing machine. Sewists with any questions or concerns should contact their sewing machine manufacturer for technical support.

Frequently Asked Questions

Q: How do I know if my bobbin is full?

A: Generally, when the bobbin is full, the thread will bunch up and become slightly larger. When this happens, all you need to do is remove the bobbin from the thread spindle and the thread will retract.

Q: What type of thread should I use?

A: The most common kinds used today are made of nylon, cotton, or polyester. It is important to select the thread that gives the proper tension and is compatible with the fabric you are sewing.

Q: Can I use an electric bobbin winder to fill the bobbin faster?

A: Yes, for experienced sewists, certain techniques may be employed for a smoother, more efficient bobbin winding process. An electric bobbin winder may be employed to wind the bobbin faster and more efficiently.

Conclusion

In conclusion, bobbin winding is an essential step in creating a successful sewing project. It is important to ensure the bobbin is compatible with your machine and filled with the correct type of thread. Understanding how to properly attach the thread to the bobbin, which technique is best for winding, and how to secure the bobbin are all essential for successful sewing. For more information or additional assistance, it is best to consult the user manual or contact the manufacturer for technical support.