Even for experienced sewers, a bent or damaged needle on a sewing machine is a frustrating problem. It’s not necessarily a sign of a damaged sewing machine; often the needle can be fixed relatively quickly and easily. To save time and prevent damage, it’s sensible to take time to understand the cause of the problem and how to address it.

As a preliminary step, it’s essential to examine the needle to determine the cause of the problem. The needle could be damaged, or it could just be bent out of shape. Remember to check for splinters or any irregularities, as these are signs of a damaged needle.

A bent needle can often be fixed by simply gripping the needle firmly and using a mallet to lightly strike the flat side of the needle until it straightens out. For a broken needle, the only solution may be to purchase a new needle. If a replacement needle is required, select the size that is specified for the type of fabric and the type of thread used.

Regardless of the cause, it’s always recommended to gently clean the needle before using it. This can be done using a lint-free cloth using a tiny bit of oil for lubrication as needed. Be sure not to lubricate too much as this could cause the needle to become clogged, leading to further problems.

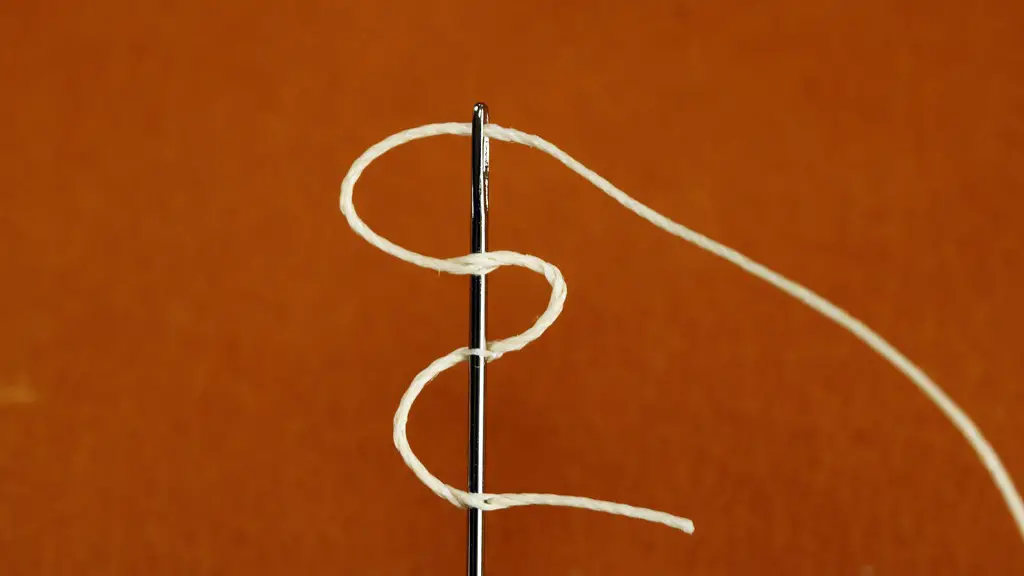

It’s also important to be conscious of the direction of thread tension. Always make sure that the needle is not under too much pressure, or else it could be forced out of shape. Additionally, the tension should be checked regularly, as this is an essential aspect of the sewing process. This can be done by gently tightening the tensioner with the fingers. If the needle and the thread form a nice loop when the tensioner is tightened, the tension is just right. If it makes a zig zag pattern, then it’s too tight and will cause a problem.

Additionally, it’s helpful to think carefully about the type of needle that is used. Needles vary in size, shape, and material, so it pays to invest in the right type for a particular job. For example, if the needle is meant to sew through thick fabric, then using a longer needle is the best option. On the other hand, if the fabric is thin and lightweight, a thinner and shorter needle will cause less damage.

Finally, the entire area should be checked for any potential problems. Look for nicks, dents, and rust on the needle or the needle plate. If there is any damage, it’s best to replace the entire needle plate or purchase a new sewing machine needle. Taking these considerations into account can help prevent future issues and help ensure that the needle won’t need to be adjusted or replaced anytime soon.

Useful Tips

Using the right type of needle is essential to ensure that the sewing machine operates efficiently. Needles are available in a range of sizes and materials, so take time to evaluate which option is best for a specific job. In general, longer and thicker needles are best for heavier fabrics, while thinner and shorter needles are best for lighter fabrics.

Additionally, always make sure that the thread tension is just right for the type of fabric and thread used. Too much tension can cause the needle to become bent, which can lead to further problems. Check the tension periodically and always make sure that the needle and thread form a nice loop when the tensioner is securely tightened.

Furthermore, it’s important to lubricate the needle regularly in order to maintain optimal performance. This can be done using a lint-free cloth and a small amount of oil. Make sure not to use too much oil, as over-lubrication can lead to clogging of the needle. Additionally, check the needle and the needle plate for any irregularities such as nicks, dents, and rust that could cause future issues.

Preventing Bent Needles

To prevent bent needles, it pays to invest in a good-quality sewing machine needle. Investing in the correct type for the job can reduce the risk of unexpected breakages and improvements in performance. It’s also important to be mindful of the tightness of the thread tension. Too much pressure on the needle can cause it to become bent or even broken. Check the tension regularly and make sure to adjust it when necessary.

Additionally, always take the time to properly clean and lubricate the needle and the needle plate to ensure efficient operation. Cleaning the components regularly can help detect irregularities or any damage before it becomes a problem. Additionally, it’s essential to replace any worn out needles or needle plates as soon as possible. Careful maintenance and prevention can help ensure that the needle won’t need to be adjusted or replaced anytime soon.

Troubleshooting Bent Needles

If a needle becomes bent, the only solution may be to replace the needle. It’s important to select the correct size for the type of fabric and thread used. Additionally, it’s recommended to grip the needle firmly and use a mallet to hit the flat side of the needle until it becomes straight.

Keep in mind that even if the needle is not broken, it no longer effectively serves its intended purpose. A bent needle can cause further problems, so it’s important to inspect it carefully before using it again. Make sure to check for any irregularities, splinters, and other damage that could indicate that the needle is broken and in need of replacement.

Conclusion

A bent or damaged needle on a sewing machine can be a frustrating problem, but it’s often possible to fix it relatively quickly and easily. Start by examining the needle to determine the cause of the problem and make sure to clean and lubricate it before using it. Additionally, select the correct size for the project and make sure not to overtighten the tensioner. Regular care and maintenance can help ensure that the needle won’t need to be adjusted or replaced anytime soon.