Troubleshooting the Basics

Mending clothes is one of the best ways to make the most of what you already have and save on buying new items. A sewing machine is a great tool to have at home if you want to fix up your clothes, or even make your own. However, if you’ve never used one before, you may find the process of winding threads onto a bobbin confusing – but with a few simple steps, you can easily master the art of threading a bobbin on a sewing machine.

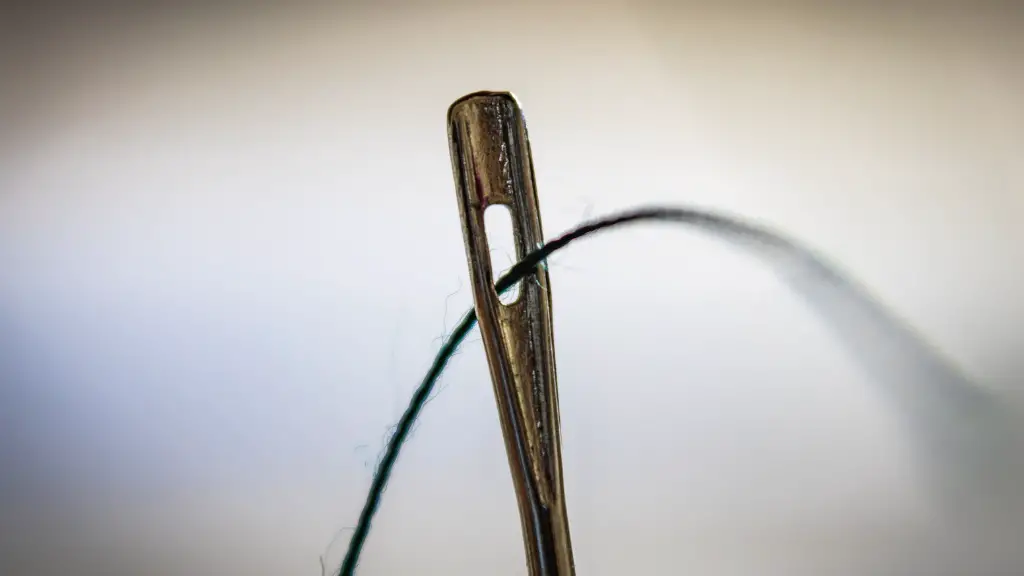

First, you need to determine the type of bobbin you are using, as some may require slightly different instructions. Typically, if you are using a standard metal bobbin, the process should be the same for most machines. Start by removing the bobbin case and stitching plate, then insert the bobbin into the bobbin case. Pull the thread through the case, keeping the spool on the machine. Feed the thread through the groove in the bobbin and pass it over the tension disc. Then, place the bobbin back into the case and onto the machine.

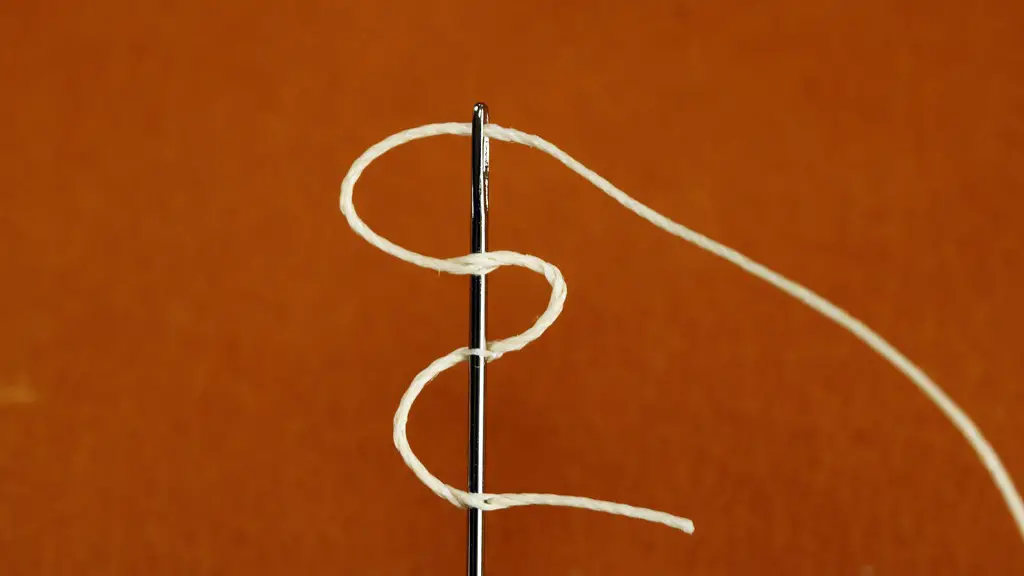

On some machines, you may need to use the bobbin winder to secure the thread on the bobbin. To do this, place the spool spindle into the corresponding shaft, fit the bobbin onto the bobbin spindle, and press the pedal until the bobbin is full. After it is full, hold onto the thread and switch the bobbin winder to the backlock function. While continuing to hold the thread, carefully remove the bobbin from the machine.

Once you have finished winding the thread onto the bobbin, you will need to make sure it is securely in place on the sewing machine. Place the bobbin, with the thread on top, into the bobbin case, and then put it back into the machine in the right direction. As a final step, gently pull the thread under the pressure foot and up through one of the holes of the upper thread guide. The bobbin should now be properly threaded and ready for use.

Adjusting the Tension for Quality Stitching

Now that you have successfully inserted the bobbin, you should be able to sew with ease. However, if you notice the stitching is loose or loopy, there may be an issue with the thread tension. To adjust the tension, start by lowering the pressure foot lever and loosening the upper thread with your hand. Check the tension discs and if necessary, adjust the screw on either side of the bobbin case. Hold the thread and turn the screw in small increments until the tension is right. Increase the thread tension by turning clockwise, and reduce it by turning counterclockwise.

When you adjust the tension discs, ensure they are the same tension on both sides. To do this, start in the middle to avoid over-tightening. If you over-tighten the discs, it will set off a chain reaction and affect the quality of the stitching. Once the tension is even and balanced, you should be able to sew with good quality stitching.

If the tension is still off, check to see if the bobbin case is correctly inserted. You can do this by taking out the bobbin case and confirming the tension discs are in the correct alignment. If so, reinsert the bobbin case to the machine and adjust the tension again.

If all else fails, check to see whether the bobbin is uneven – it should have a mandatory end. All the thread should remain secure on the bobbin without any loose ends.

Caring for Bobbins and Accessories

If you want to make sure everything is working well on your sewing machine, you should take a few steps to ensure it is properly maintained. Always store extra bobbins and accessories in a safe place to make sure they are in good shape. Additionally, make sure you clean the bobbin area of your machine regularly to keep lint, dust and thread from collecting.

If you find yourself using a lot of different thread types in a short period of time, you should be replacing the bobbin regularly for best results. Old bobbins can become worn or misaligned, so it’s always best to have a spare handy. The same goes for the needle – it is recommended to change the needle after 8-10 hours of sewing.

Avoid Common Issues with Bobbins

From threading problems to tension issues, there are many issues that can arise when it comes to sewing with bobbins. To avoid these frustrating problems, make sure you understand the basics of bobbin winding and tension. Additionally, always use the right type of thread for the project and make sure the needle is compatible with the thread.

When it comes to a bobbin machine, make sure to check the tension discs every time you put in a new bobbin. If you have to adjust the tension regularly, try to find out if the problem is caused by the bobbin or the machine itself. Also, make sure to replace the bobbin after every 8-10 hours of use.

Threading the Bobbin Correctly for Smooth Sewing

Threading a bobbin correctly can be a tricky process, but once you get the hang of it, it is quite simple. Start by determining the type of bobbin, then insert the bobbin into the bobbin case and place the case back into the machine. On some machines, you may need to use the bobbin winder to secure the thread. Finally, always make sure to adjust the tension when required and replace the bobbin after 8-10 hours of sew.

Troubleshooting Bobbin Issues

If you experience issues with the bobbin, try to establish the cause. If the bobbin is uneven or the tension is off, make sure to adjust it. Additionally, make sure to regularly clean the bobbin area of your machine to keep it from collecting dust and lint. If all else fails, replace the bobbin and be sure to check the needle before starting.

Using the Bobbin for Professional Results

If you are looking to get professional results with a sewing machine, mastering the art of threading a bobbin is essential. To get the best results, make sure you understand how bobbin winders, tension discs and bobbins work. Additionally, always use the right type of thread and ensure that the needle and bobbin are in the correct alignment. With all of the necessary knowledge in place, you are sure to achieve the desired results.

Determining the Best Bobbin for Your Project

Choosing the right bobbin for your project is essential for successful sewing. If you’re unsure about the type of bobbin you should use, consult the instruction manual for your sewing machine and determine the type, size and shape of the bobbin required. Also, be sure to check the compatibility ofthe thread, and avoid using too much thread. Finally, when you have finished threading your bobbin, take the time to adjust the tension correctly to ensure the perfect stitch.