Have you ever been mid-sewing only to have your thread start bunching up and won’t bow? This can be an incredibly frustrating experience. It seems like something so simple has now become so complicated. If you’re trying to do a simple patch up job or even a whole project, this interruption in the process can be a nuisance. Don’t worry though, your thread doesn’t have to remain bunched up as you can easily fix that issue. Here’s a simple guide on how to fix bunching thread on sewing machine.

Check the Spool Alignment

The first of the many potential causes to examine when attempting to fix bunching thread on sewing machine is the spool alignment. If your threads are bunched up and won’t bow, it could be that your spool is not aligned with your needle correctly. Before you start sewing, check the alignment of your needle and spool and adjust them to be in line with one another. To do this, use a measuring device like a ruler or tape measure. Make sure the alignment is not too tight or too loose. Also check that the needle is not bent or damaged from previous use. If the needle needs to be replaced, take out the old one and carefully insert the new one so it aligns with the spool.

Replace the Thread

Occasionally, replacing the thread can also fix bunching thread on sewing machine. It’s likely that the old thread is tangled or knotted. Check the thread for knots, snags, or loops which can cause the thread to bunch up and get stuck. If there are any knots or snags, replace the thread and start sewing again. When removing the old thread, use a thread clipper or a sharp pair of scissors to get an even cut and avoid further damages.

Clean the Tension Discs

An obvious potential cause of bunching thread is the tension discs which can be filled with lint and debris over time. This can make the needle threader difficult to use, creating knots and bunching as it passes through the discs. To clean out the tension discs, use a toothbrush and a cotton swab. Gently press the cotton swab or toothbrush between the discs, move it in a circular motion to remove the lint, then dry it off with an old cloth. After you do this, test it out a few times by running the needle threader through the discs. They should slide through easily and without difficulty.

Check the Stitch Length

Another possible cause of bunching thread is the stitch length. If the stitch length is set too high, the thread can become caught up in the fabric as it moves. To fix this issue, lower the stitch length on your machine to 3 or 4 mm. You should also clean the needle plate and the feed dog to make sure the fabric moves freely through the machine. This will help the thread move smoothly. Additionally, the type of fabric you’re working on could be a factor in the bunching. Make sure you’re using the right type of thread for what you’re working on. Some fabrics need specific thread, like waxed or water-resistant thread, to avoid bunching.

Replace the Bobbin

The final potential cause to consider when attempting to fix bunching thread on sewing machine is the bobbin. If the bobbin is damaged or worn out, it can snag the thread and not be able to pull it through the fabric. Try replacing the bobbin to see if it solves the issue. When replacing it, take out the old one and insert the new one carefully. Make sure to follow the correct winding directions for your machine as this is important for the bobbin to work correctly in the machine.

Troubleshooting

If after all this, your sewing machine is still having trouble, the best thing to do is to consult the user manual and use the troubleshooting guide in the back. This should help you identify the problem more quickly. Additionally, you can take the machine to a specialist who can help you diagnose and fix the issue.

Advanced Troubleshooting

If you are having more complicated or persistent issue with bunching thread, a professional may be the best approach. Take some pictures of the area of the machine in which your issue is occurring and send them over to a professional sewing machine repair technician. Describe the issue in detail and they should be able to give you advice and a solution on what to do. Make sure to inquire with the technician if they have a repair fee before they start looking into repairing the machine.

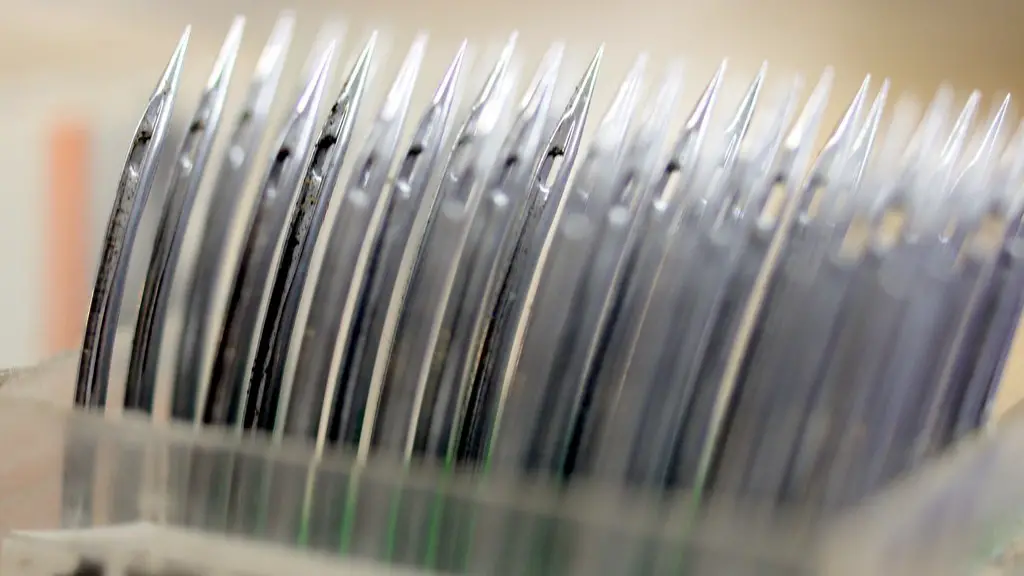

Substitute the Needle

Sometimes switching out the needle can fix bunching thread on sewing machine. Over time, needles can become blunt and this can cause the thread to catch on the needle and create knots. To solve this, replace the needle with a new one that is the right size and type of needle for the project. Make sure to use the right size screwdriver to switch out the needle and insert the new one. Your machine should come with a needle size guide which you can use to choose the correct size needle for the project.

Check the Thread Tension

Lastly, the thread tension may need to be adjusted on your machine. Usually the top thread tension should be a little looser than the bottom thread tension. This is so the two threads can “lock” together. If the tension is too high or too low, the top and bottom threads won’t lock together and this may cause bunching. To check the tension, take off the face plate and carefully adjust the tension dial. Increase the tension if the stitch is too loose, or decrease the tension if the stitch is too tight.

Check the Needle Plate

The needle plate is a small metal plate that is found underneath the face plate. This part slides back and forth to evenly feed the fabric while you’re sewing. It is important to check this plate to make sure there are no burrs, nicks, or scratches on the plate. These imperfections can catch the thread and cause it to bunch up.

Examine the Bobbin Case

Another area to examine when trying to fix bunching thread on sewing machine is the bobbin case. The bobbin case holds the bobbin in place and it should be clean from dirt, lint, and other debris. If the case is dirty, it can make the bobbin slip around, creating uneven tension and resulting in bunching or thread nesting. To clean it, use cotton swabs or a brush to gently brush away any dirt or lint.

Use a Magnet

Sometimes thread can get caught on the underside of the machine and you need to use a magnet to locate it. Place a magnet on the outside of the machine and move it around until you find the thread. Pull the thread through the machine with the magnet, then check the tension and needle plate again to make sure the tension is even and there are no imperfections in the plate.