Basic Troubleshooting Tips

Most of the time, problems with the timing of a Janome sewing machine can be easily fixed without having to take it in to the repair shop. In order to fix the timing, it is important to have a thorough understanding of what the timing is, what it does and how to adjust it. It is also important to pay close attention to any cause that may have led to the problem in the first place.

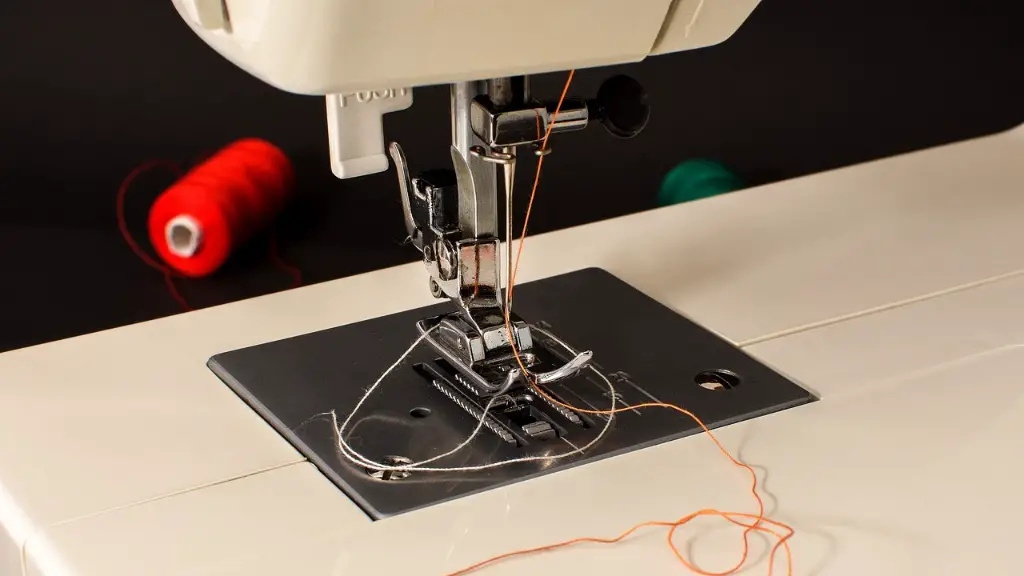

The timing of a machine governs how the upper and lower thread work with each other. When the timing of the machine is off, it can cause the tension to be uneven, resulting in a poor stitch. If the timing is too far off, the machine can jam or skip stitches. Additionally, if the timing of the machine is not caught and adjusted, there can be major damages caused to the machine.

To determine if the timing is off, the bobbin case should be removed from the machine and the flywheel should be checked for the correct positioning. The handwheel should be turned counterclockwise until the red arrow lines up to one of the numbers on the faceplate. Then the red arrow should be checked to ensure that it is pointing in the same direction as the handwheel. If the red arrow is not in the same direction as the handwheel, the timing may be off.

In order to fix the timing on the Janome sewing machine, the first step should be to adjust the flywheel. To adjust the flywheel, the thumbscrew should be loosened and the handwheel turned. The flywheel should be adjusted until the red arrow lines up with the number position marked on the faceplate. The flywheel should be tested to make sure it is not too tight or too loose.

After the flywheel has been adjusted, the needle should be checked for proper positioning. It is important to ensure that the needle is in the center of the bobbin case and not too far off to one side. If the needle is not properly positioned, it can cause the stitches to be uneven and cause problems with the machine. The needle should be checked regularly in order to ensure that it is in the proper position.

The next step to fix the timing on the machine is to adjust the tension. The tension should be checked by turning the handwheel of the machine and observing how the material slides under the stitching area. If the material slides too easily, the tension should be adjusted. This will help the machine to maintain the correct tension and will help with the overall stitch quality.

Finally, the machine should be tested for accuracy after the flywheel and tension have been adjusted. The machine should be test sewn on a scrap piece of fabric to make sure that the stitch quality is even and that the tension is correct. If the stitches are uneven or the tension is off, the machine should be checked and the adjustments made again.

Common Problems & Solutions

One of the most common problems with Janome sewing machines is the timing being off and the upper and lower threads not working properly together. Fortunately, this problem can be easily fixed. Check the needle positioning and the tension as these could be the cause of the problem. If the needle is not in the middle of the bobbin case or the tension is off, the machine will have difficulty producing even stitches. Make sure to adjust the tension and the needle to the correct position before attempting to adjust the timing.

Another common problem is not making sure the flywheel is properly adjusted. The flywheel must be in the correct position for the machine to produce even and consistent stitches. To adjust the flywheel, loosen the thumbscrew and turn the handwheel until the red arrow lines up with the number position marked on the faceplate. Make sure to check the flywheel periodically to ensure it is in the correct position.

Finally, Janome sewing machines can be sensitive to buildup. If the bobbin area of the machine has accumulated dust, lint or any other debris, it can affect the tension and the overall performance of the machine. It is important to make sure that the bobbin area is cleaned periodically to ensure the best performance. Make sure to use an approved cleaner and to follow the instructions provided.

Prevention Techniques

In order to prevent problems with the timing of a Janome sewing machine, it is important to use high quality spools and bobbins. Low quality spools and bobbins can lead to a buildup of lint or dust in the bobbin area which can interfere with the machine’s performance. Additionally, it is important to make sure the needle is in the correct position and the tension is adjusted properly.

In addition to using good quality supplies, it is important to make sure the machine is oiled properly. Many Janome models come with an oiling kit that can be used to extend the life of the machine. Additionally, it is important to make sure to use the proper needle size for the type of fabric being sewn. If the needle is too thick for the fabric, it can cause the machine to bind up and cause problems with the timing.

Finally, it is important to make sure to clean the machine periodically. Over time, dust, lint and other debris can accumulate in the bobbin area and affect the performance of the machine. Make sure to use an approved cleaner and to follow the instructions provided.

Replacement Parts & Techniques

If the timing of the Janome sewing machine cannot be fixed with the methods outlined above, it is time to consider looking into replacement parts. Replacement parts can be acquired through the manufacturer or from an authorized repair shop. Replacing certain parts such as the flywheel or the tensioner can help to get the machine back up and running and give it a longer lifespan.

When it comes to replacing parts, it is important to make sure to use genuine Janome parts. While third-party spare parts may be less expensive, they can be of a lesser quality and can affect the performance of the machine. Additionally, using genuine parts ensures that the machine is covered by warranty, should any other problems arise.

It is also important to make sure that the machine is properly calibrated after any parts have been replaced. This involves setting the tension, adjusting the flywheel and ensuring that the needle is in the correct position. These steps are essential for ensuring that the machine is producing even stitches and for maintaining the longevity of the machine.

Tools & Accessories

In addition to replacement parts and techniques, there are a few tools and accessories that can help to make the job of maintaining a Janome sewing machine easier. A good quality thread stand and bobbin winder are essential for ensuring that the thread stays in place and for winding bobbins quickly and easily. Additionally, a good-quality lint remover is essential for cleaning the bobbin area and keeping the machine running smoothly.

It is also important to make sure to have the right needle for the job. If the needle is too thick, it can cause the machine to bind up and have difficulty producing even stitches. Make sure to use the proper needle size and change it regularly to ensure the best performance.

Finally, a good-quality service manual is essential for troubleshooting and repair work on the Janome sewing machine. A service manual will provide detailed instructions on how to adjust the timing and other essential functions. Additionally, a service manual will provide helpful troubleshooting tips and tricks for maintaining the machine.

Maintenance Tips

Regular maintenance is essential for keeping a Janome sewing machine running smoothly and for extending its lifespan. Make sure to check the timing periodically to make sure that it is in the correct position and to adjust it if necessary. Additionally, make sure to clean the bobbin area regularly and to make sure the needle is in the correct position.

It is also important to keep an eye on the tension. If the tension is too tight or too loose, make sure to adjust it accordingly. If the tension is not adjusted properly, it can lead to problems with the timing of the machine. Additionally, make sure to use high quality spools and bobbins as these can affect the overall performance of the machine.

Finally, it is important to make sure to oil the machine regularly. Make sure to use an approved oiling kit and to follow the instructions provided in order to extend the life of the machine. Additionally, make sure to inspect the machine periodically for any signs of wear or damage that may affect the overall performance of the machine.