Introduction

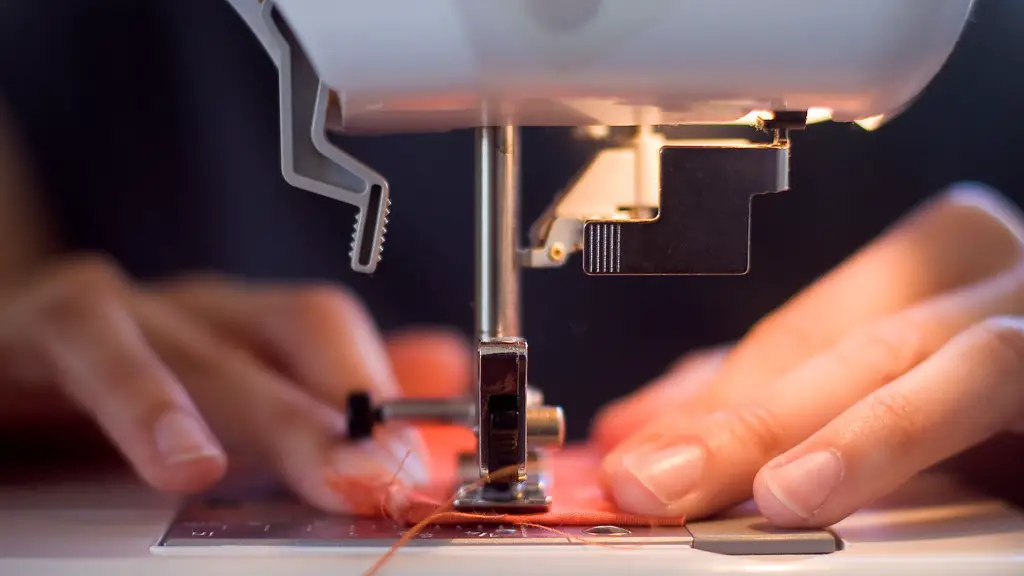

When sewers use a Singer sewing machine, they expect it to be easy to use and able to sew intricate patterns and stitches. Despite being a reliable piece of equipment, all Singer models require tuning once in a while. This is primarily due to the movable parts of the machine such as the needle and the stitching arm. In particular, the timing of the hook assembly is critical in order to ensure that the stitches are produced correctly and uniformly. A simple step-by-step guide to fixing the timing of the hook assembly on a Singer sewing machine will help sewers get back to creating beautiful garments and projects.

Problem Diagnosis

When the timing of the hook assembly of a Singer sewing machine is off, it often results in skipped stitches or a whipping effect on the fabric. To determine when the timing is off, it is important to first check the condition of the needle and thread. For example, if the thread is not properly threaded through, it will cause tension problems and result in broken stitches, regardless of the timing. If the needle is bent or corroded, the needle will not pass through the fabric easily and the patterning may appear uneven.

When these issues have been ruled out, the next step is to check that the bobbin and case are properly placed. The bobbin and case should be seated in the same level and will require retightening if it has moved out of place. To test the positioning of the bobbin, pull it up slightly to ensure that it is snug against the needle plate. If the bobbin does not rise when it is pulled, the tension is incorrect and the needle plate may need to be adjusted.

Adjusting the Needle Plate and the Bobbin Case

Once the needle and thread have been checked and the bobbin and case have been confirmed as correctly placed, the next step is to adjust the timing of the hook assembly. To do this, the needle plate and bobbin case need to be adjusted.

For the needle plate, it is best to start by loosening the needle plate screws on the back side of the bed of the machine. After these screws have been loosened, the needle plate can be adjusted with a small screwdriver. Make sure that the needle plate is positioned correctly and that the timing mark is visible. Once the needle plate has been adjusted, gently press it down until it clicks into place.

For the bobbin case, it should also be adjusted with a small screwdriver. Start by loosening the bobbin case screws on the back of the bed. Once these screws have been loosened, the bobbin case can be adjusted. Make sure that the bobbin case is positioned correctly and that the timing marks are visible. Once the bobbin case has been adjusted, gently press it down until it clicks into place.

Tightening the Needle Plate and Bobbin Case

After the needle plate and bobbin case have been adjusted, the next step is to tighten the screws of both parts. Start by tightening the needle plate screws, making sure not to overtighten them as this can cause the needle plate to become misaligned. Once the needle plate screws have been tightened, the bobbin case screws should also be tightened. Again, make sure not to overtighten the screws as this can cause the bobbin case to become misaligned.

Checking the Hook Timing

After the needle plate and bobbin case have been adjusted and tightened, the next step is to check the hook timing. To do this, it is best to start by putting a piece of scrap fabric under the needle and slowly moving the needle up and down. If the hook catches the thread on its way up, the timing is correct. If not, it may be necessary to repeat the above steps.

After the hook timing has been adjusted, it is important to test the machine on a few pieces of fabric. Doing this will ensure that hook timing is correct and that the machine is producing the correct patterning. It is always important to test the machine after making any adjustments, no matter how minor the adjustment may be.

Regular Maintenance

Regular maintenance is important in order to keep the hook timing of a Singer sewing machine accurate and reliable. This includes oiling the movable parts, using the correct-sized needle, changing the needle regularly and cleaning the machine regularly. All of these steps will help ensure that the hook timing remains accurate and the machine is working correctly.

Conclusion

Correct hook timing on a Singer sewing machine is critical to ensuring that the machine is producing stitches accurately and smoothly. This guide provides a step-by-step approach to adjusting the hook timing, which should ensure that the machine is working correctly and producing the desired patterning. It is important to remember to regularly maintain the machine to ensure that the hook timing remains accurate and the machine continues to produce beautiful stitches.