When a sewing machine is used for a long period of time, the stitching can loosen up, making it very difficult to get the sew job done correctly. When this happens, it can be a very frustrating experience and you may feel like it is impossible to fix the problem. This article is here to help guide you through how to fix loose bottom stitch on a sewing machine so that you can get back to making something special.

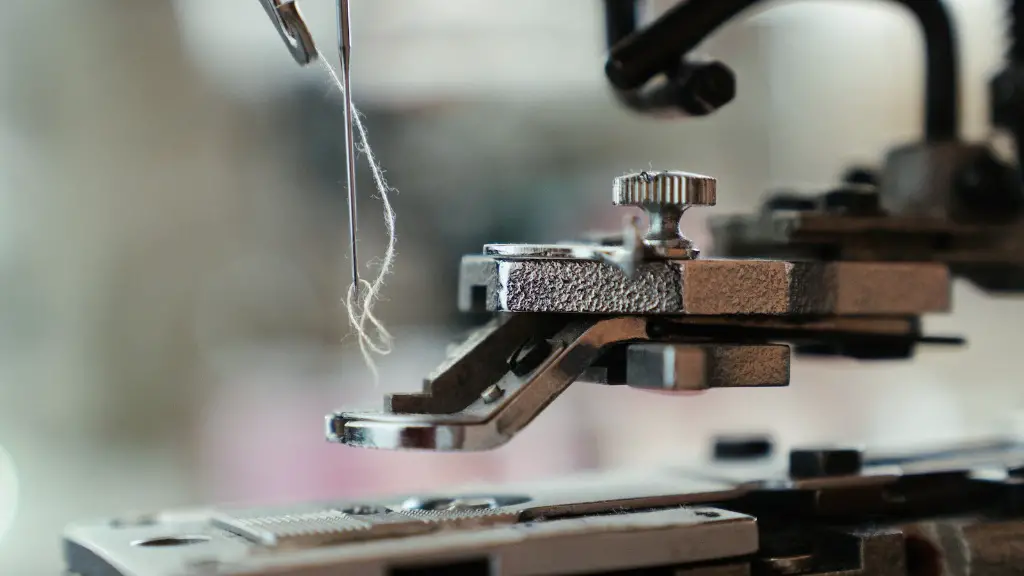

The first step in fixing a loose bottom stitch on a sewing machine is straightening the needle. If the needle is not straight, it can cause the stitching to be loose. To straighten the needle, first, turn the machine off and remove the needle. Then, take a flat surface and press the needle down on the table. If it’s still not straight, use pliers to press each end of the needle at the same time, until the needle is straight.

The second step is checking the needle position. Make sure the needle is in the correct position, slightly to the left of the presser foot, when it is positioned for sewing. If the needle is not in the correct position, the stitching will not be tight and can be loose at the bottom.

Next, check the tension of the needle. You can do this by testing the tension on a scrap piece of fabric. If the tension is too tight or too loose, it can cause the sewing machine to stitch loosely. To adjust the tension, find the tension dial on the machine and adjust the settings until the tension is correct.

You should also double check that the right needle and thread are being used. For example, if you’re using a lightweight fabric, you need to use a light weight needle and thread. If you are using a heavyweight fabric, you need to use a heavyweight needle and thread. If you don’t, the stitches could become loose.

Finally, check the bobbin case to make sure it is seated properly. To do this, simply remove the bobbin case from the machine and make sure that it is properly seated. If it is not seated properly, it can cause the stitching to be loose. If it is not seated properly, you may need to adjust the bobbin case or replace it altogether.

Follow Machinery Manufacture Instructions

In order to ensure that you are following the correct instructions, it is important to follow the manufacturer’s instructions that came with the machine. This will ensure that you have all the correct information and that no steps are being missed when trying to fix the problem. Additionally, be sure to clean the machine regularly since dirt and dust can affect the stitching. If a step-by-step instruction manual is not available, search for it on the internet.

If a sewing machine is used for a long time and is not properly maintained, it can develop loose stitch at the bottom. Following these steps is a great way to fix loose bottom stitch on a sewing machine and get back to the details. After the process of fixing the problem is complete, start the machine again and make sure the sewing is even and secure.

Common Mechanical Problems

In addition to loose bottom stitching, many sewing machines also experience common mechanical problems that can affect the quality of stitching. This includes broken needles, broken bobbins, worn out belts, and jamming of the machine. These issues can be caused by a variety of factors, such as incorrect threading, excessive fabric weight, or wrong needle and thread size.

When it comes to broken needles, the most common cause is using the wrong needle size. A sewing machine needle must be the same size as the thread being used. If the thread is too thick, the needle can break after several uses. To avoid this problem, make sure to thread the machine correctly and use the correct needle size.

Broken bobbins can be caused by the needle not being in the correct position when sewing, and this can cause the bobbin thread to become tangled. To prevent this from occurring, make sure that the needle is set correctly and check it often. Additionally, a worn out belt can cause the stitching to become loose after a long period of use. If the belt is cracked or broken, it should be replaced immediately.

Finally, some machines may jam up after using them for a while. To prevent this, it’s important to clean and lubricate moving parts of the machine periodically. This will prevent the machine from accumulating too much dust and debris, which could cause it to jam up.

Purchasing a New Sewing Machine

In some cases, the best solution to the problem of loose bottom stitch may be to purchase a new sewing machine. There are many different sewing machines on the market today, ranging from basic machines that only do a handful of stitches, to high end machines that are capable of completing complex sewing projects.

When selecting a new machine, it is important to consider the types of projects you want to do with it. If you are planning to do a lot of quilting, for example, you may want a machine that has multiple stitch settings and a quilting feature. Additionally, consider the portability of the machine, as well as ease of use and cleaning.

In addition, pay attention to the type of motors used in machines. Generally speaking, machines with a direct drive motor are more reliable and require less maintenance. Machines that have belt drives and pulleys can be more prone to maintenance and repair.

Finally, be sure to research the company that manufactures the sewing machines. Make sure that the company has a good reputation for quality and customer service. Doing a bit of research beforehand can save a lot of frustration and money in the long run.

Maintenance Tips for a Sewing Machine

In order to keep a sewing machine in good working order and prolong its lifespan, it is important to take care of it. It is important to clean the machine after each use and make sure all parts are operating properly. Inspect the machine regularly and make sure that needle plates, bobbin cases, and other parts are not cracked or broken.

It is also important to regularly oil the machine’s parts and replace the needle when it becomes dull. Additionally, remember to maintain the machine’s timing and tension appropriately. Properly tensioned machines produce precise and even stitching which can prevent loose bottom stitching.

While many sewing machine problems can be fixed with the steps listed above, it is also a good idea to take the machine to a professional for a checkup once a year or whenever there are serious issues. Professionals have the expertise to identify any potential issues and can offer advice on how to keep the machine running smoothly.

Troubleshooting Tips

Sometimes, the cause of a loose bottom stitch may not be so obvious. If the above steps don’t fix the problem, there may be an underlying issue that needs to be addressed. If a sewing machine is new or recently serviced, the problem may be due to incorrect settings. Be sure to consult the manual to make sure all settings are correct.

If the problem persists, it may be a good idea to have the machine checked by a professional. Not only can they help identify the problem, but they can also make sure the machine is in proper working order and that all potential underlying problems are addressed.

Preventative Maintenance

A good way to prevent the occurrence of loose bottom stitch is to practice preventative maintenance. Regular maintenance can help make sure that the machine is in top condition and can extend its lifespan. This will also ensure that the machine runs smoothly and offers consistent results.

Make sure to clean the machine after each use and replace the needle when it becomes dull. Additionally, examine the bobbin case and needle plate to make sure they are not cracked or damaged. Finally, lubricate the machine’s moving parts regularly to keep it running smoothly.

When it comes to fixing loose bottom stitch, it is important to remember that it can be a complex problem with multiple causes. With the right attention to detail and proper maintenance, however, it is possible to get the sewing machine back to proper working order and make sure the problem does not occur again.