Troubleshooting Sewing Machine Tension Problems

Most sewing problems, like puckering and uneven stitches, are usually tension-related, and can be easily fixed by adjusting the tension of the sewing machine’s upper thread. In order to adjust the tension, it’s important to first identify the issue and to become familiar with the sewing machine’s controls and functions. All sewing machines come with a manual that will list the directions for adjusting the tension.

Identifying Tension Problems

Before adjusting the tension, inspect the fabric for misplaced or malfunctioning machine parts, or for improper threading. The upper thread should be placed near the spool pin, the lower thread should stay through the take-up lever, and both lines of thread should be connected to the needle properly. If everything appears to be normal, take a look at the upper and lower stitches. Uneven stitches or too-tight stitching indicate an increased tension on the upper thread. Whereas too-loose stitches or skipped stitches suggest a low tension on the upper thread.

When inspecting the machine’s thread tension, it’s also essential to consider the fabric type. Lightweight fabrics like voile and organza require higher tensions whereas heavier fabric types like denim and upholstery require lower tension. The thread type used also plays a role in tension. Thread flexibility and size affect the tension required for special projects like embroidery or quilting.

Adjusting Thread Tension

Once the thread tension issue is identified, consult the sewing machine manual and follow the instructions for adjusting the thread tension. The two most common methods for adjusting are either via the tension control dial, switch or screw, or by manually decreasing tension. To manually adjust, users can gently pull the upper thread and upper tension disks until the thread pieces appear balanced on either side of the machine.

For first-time sewers and those inexperienced in adjusting the thread tension, it’s recommended to begin with just a small turn of the tension dial and then test a few stitches on scraps of fabric. Adjusting the tension incrementally and testing frequently will help deliver the desired stitch quality. After each trial-and-error session, remember to record the tension settings with a pencil on a piece of masking tape affixed to the machine.

Machine Lubrication and Repair

If tension problems still exist, it’s time to lubricate the machine and check for any loose pieces. Consult the sewing machine manual and locate the correct lubricants; some machines require specialized lubricants. Before lubricating the machine, turn it off and disconnect it from any power source. Apply the lubricant in small amounts on specific machine locations. Make sure to read the directions carefully and never lubricate the motor.

Sometimes tension problems are caused by underlying machine damage or a malfunctioning part. If you consistently experience tension issues or if the machine does not work after adjusting the tension, the best course of action is to take the machine to a certified sewing machine technician.

Using the Right Presser Foot

The presser foot exerts constant pressure on the material that’s fed into the machine. All machines come with different presser feet; the right foot should be chosen depending on the fabric type and project requirements. As an example, straight stitches usually require a special presser foot whereas zigzag stitches require another. It’s important to consult the manual for instructions on how to replace the presser foot. Incorrect presser foot selection could lead to tension issues.

Setting Appropriate Stitch Length

The recommended stitch length for standard straight stitching is on average 2.5 to 3.5mm. When tackling more intricate tasks like basting or embroidery the stitch length should be decreased. Sewers should be mindful of all the instructions and recommendation that come with their sewing machine.

Finding the right tension requires practice and patience. Before each sewing project, inspect the machine’s parts, use the right presser foot, check the stitch length and test the sewing machine with a few trial stitches on a scrap piece of fabric. Finding the ideal tension takes time and experience, and it’s essential to understand that the setting requirement change from fabric to fabric. With the right techniques and attention, sewers can easily fix most of the tension-related problems.

Stitch Types and Patterns

Sewing machines come with different stitch styles that offer an array of creativity and functionality. Zigzag stitches, for example, are used to finish raw edges, and thus require a much lower tension than a straight stitch that often involves negotiating curved corners or tight corners. Always refer to your sewing machine manual for specific instructions on how to set the tension for different stitch types or patterns. Also, practice on scrap fabric can help determine the right tension and desired quality.

Thread Weight and Types

Selecting the right type of thread is essential. Generally, light-weight threads, like those used on lightweight fabrics, require more tension than heavier-weight threads. It’s also important to make sure the thread is compatible with the fabric. For example, poly-cotton threads work best with lightweight fabrics whereas heavier fabrics such as denim require stronger threads like cotton.

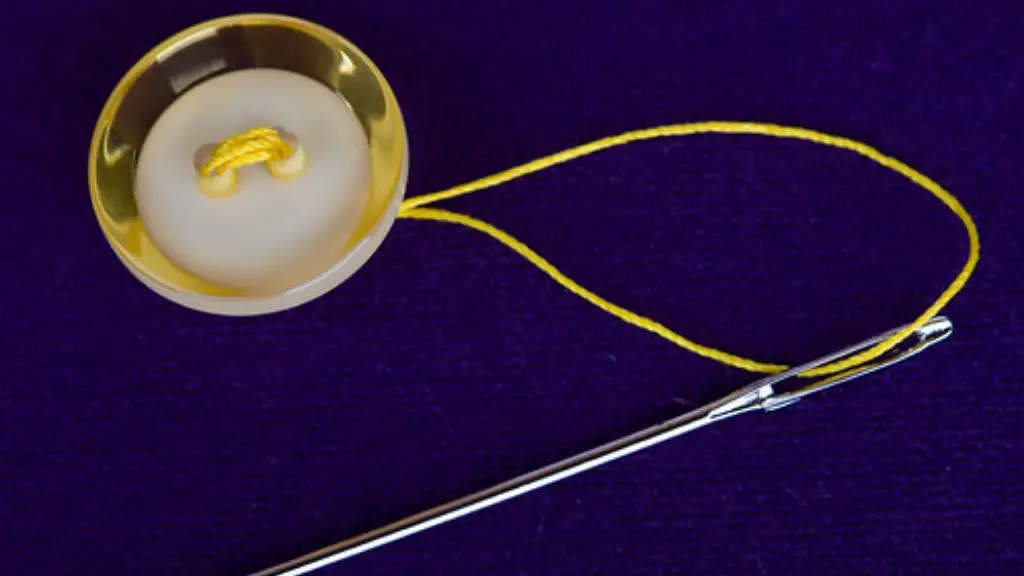

Bobbins and Needles

Incorrect bobbin winding may cause tension issues. Ensure that the bobbin is wound correctly and that only the thread made specifically for the sewing machine is used. Likewise, make sure to use the right size needle for the fabric and thread type. Using the wrong sized needle could create skips and tension issues.

Tension Testing on Test Pieces

The tension settings may vary from project-to-project, and hence testing the tension is essential. Before starting any sewing project, practice with scrap fabric and fine-tune the tension accordingly. Take note of the settings to ensure reproducibility and accuracy in future projects.