Preparing To Fix The Bobbin

Learning how to fix the bobbin on a sewing machine is an essential skill for anyone interested in sewing. Not only is this a useful skill for everyday maintenance, but it can also be beneficial to develop an understanding of how the machine works and how different components interact with each other. Before learning how to fix the bobbin, it is important to understand its function and the elements required for successful operation.

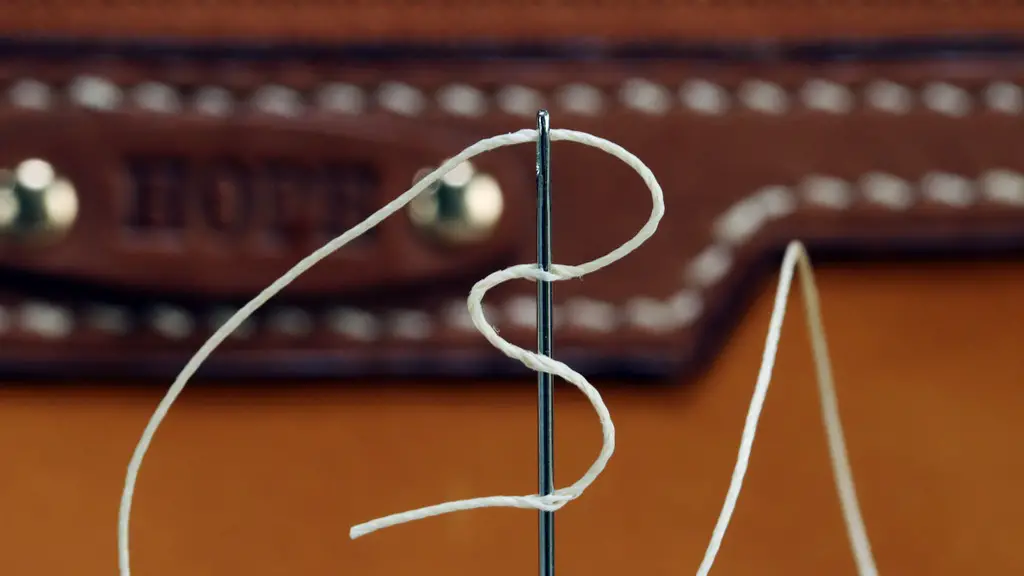

A bobbin is used in sewing machines to feed thread for top stitching. It is used together with the yarn spindle to shuttle the thread through the eye of the needle. Typically, it is a plastic or metal cylinder or spool that has one end with a small hole that is used to insert a piece of thread. The other end is used to attach the bobbin securely in the sewing machine. When it is inserted into the machine, the bobbin’s drive gear is responsible for the rotation of the bobbin when the machine is in motion.

To ensure that a bobbin functions correctly, it is important to check various elements including the tension of the thread, the alignment of the drive gear, and the distance of the bobbin from the needle. If any of these elements are incorrect, it can cause the machine to malfunction, leading to skipped stitches or bobbin problems.

Once these elements have been checked, the next step is to determine how to fix the bobbin. According to experts, this can be done in a few simple steps. First, it is important to check for any loose or exposed wiring. This can be identified by removing the bobbin from the machine and looking for signs of damage. If the wire is not in place, it should be re-attached, ensuring that the connection is secure.

Once the wiring has been checked, it is time to examine the bobbin itself. Inspect the bobbin to check that it is properly wound and that the thread is properly tensioned, making sure that the thread is evenly distributed around the bobbin. If any of these elements are not correct, it may be necessary to re-wind or adjust the tension.

Once the bobbin has been inspected and the thread is properly tensioned, it is then necessary to properly insert the bobbin into the machine. To do this, make sure that the bobbin is correctly aligned with the drive gear, ensuring that it is in the correct direction and that the drive gear is correctly engaged. This will ensure that the bobbin will rotate correctly and that the thread will be fed through properly.

Changing The Bobbin

If the bobbin is in a poor condition or needs to be replaced, it is important to know how to correctly change the bobbin. First, the old bobbin needs to be removed from the machine. To do this, locate the bobbin case and open it carefully. Next, look for the tension spring and remove it from the bobbin case, and then carefully remove the bobbin from the machine.

The next step is to insert the new bobbin into the machine. First, make sure that the bobbin is properly wound with the appropriate tension. Once this is done, insert the new bobbin into the tension spring, making sure that the thread is aligned with the drive gear, and then secure it into place. It is also important to check that the drive gear is properly engaged and that the bobbin is securely attached.

Once the new bobbin has been inserted, it is then time to re-thread the machine. To do this, it is necessary to make sure that the top thread is in the right place in the spool, and that the thread is threaded through the take-up lever. Then, take the end of the thread and insert it through the bobbin winding dial, making sure that it is snugly fitted. Finally, connect the top thread to the bobbin thread, making sure that the thread is tensioned correctly.

Troubleshooting Common Problems

When working with a sewing machine, it is not uncommon to encounter some problems. One of the most common problems is when the bobbin fails to rotate correctly or is not feeding the thread in the correct manner. If this is the case, the cause of the problem can usually be identified by checking the bobbin and ensuring that the drive gear is correctly engaged, and that the bobbin is correctly tensioned.

Another common problem is when the thread does not appear to be feeding correctly. In this case, it is important to ensure that the thread is correctly tensioned and that the spool is correctly aligned. If the problem persists, it may be necessary to replace the bobbin or adjust the tension of the thread.

It is also possible that the bobbin may not be correctly secured in the machine, which can cause the machine to malfunction. To avoid this problem, it is important to make sure that the bobbin is correctly fitted in the machine, and that the drive gear is correctly aligned. Additionally, it may be necessary to adjust the tension of the thread in order to ensure that the bobbin is correctly secured.

Ensuring Proper Care and Maintenance

Ensuring proper care and maintenance of a sewing machine is essential in order to ensure its optimal functioning. With regular maintenance, it is possible to prevent the occurrence of problems, such as bobbin malfunctions. To ensure proper care, it is important to check for any signs of wear and tear, and to replace any damaged or worn components as necessary. Additionally, it is important to regularly clean the machine and ensure that the bobbin and spool are correctly wound and tensioned.

It is also important to ensure that the machine is properly lubricated. Most sewing machines come with their own lubricant, and it is important to use this lubricant in order to keep the machine’s moving parts properly lubricated. Additionally, it is important to keep the machine’s interior and exterior clean and free of dust and dirt in order to ensure that the machine is functioning as it should.

Finally, it is important to be aware of any changes in the machine’s performance or functioning. If the machine starts to malfunction or seems to be operating slower than usual, it is a sign that there may be an issue that needs to be addressed. In such cases, it is important to seek the help of a professional for further inspection and repair.

Checklist for Proper Operation

When it comes to keeping any machine running properly, it is important to establish a regular maintenance routine. A checklist can be a useful tool to ensure that all elements are correctly checked and adjusted as necessary. For sewing machines, the following checklist is usually recommended in order to ensure proper operation:

- Check that the bobbin is correctly tensioned and wound

- Ensure that the drive gear is correctly engaged and aligned

- Check the wiring for any signs of damage or loose connections

- Replace any damaged or worn components as necessary

- Clean the machine regularly and ensure that the interior and exterior are free from dust and dirt

- Lubricate the machine regularly according to the manufacturer’s instructions

- Check for any changes in the machine’s performance or functioning

Following this checklist regularly can help to ensure that a sewing machine is kept in proper working order, and reduce the risk of malfunctions such as bobbin issues.

Seeking Professional Assistance

When it comes to learning how to fix the bobbin on a sewing machine, it is important to remember that some skills may require the assistance of an experienced technician. While it is possible to learn basic maintenance skills, it is best to seek the help of a professional if the issue is complex or beyond the scope of someone’s abilities.

Additionally, in some cases, a professional may be able to diagnose and repair any issues that are not found during regular maintenance. They can also provide advice and recommendations on the best products and techniques for maintaining the machine.

It is also important to remember that regular maintenance and care can help to extend the life of a sewing machine. By taking the time to ensure that all elements are in proper working order, and seeking professional assistance when necessary, it is possible to keep a sewing machine in good condition for longer.