When it comes to sewing, maintaining the right tension on your sewing machine is key. If the tension is too tight, the fabric can fray, while if it’s too loose, the stitches won’t hold. To get the tension just right, it’s important to understand what causes it to be unbalanced and how to fix it.

A common cause of tension issues is the type of fabric you’re working with. Fabrics can vary in thickness, from lightweight silks to heavyweight denim, and the tension needs to be adjusted accordingly. It’s also important to make sure the fabric is aligned correctly in the sewing machine or the tension could end up being off balance.

Thread can also impact the tension. Using a low-quality thread can result in skipped stitches and uneven tension. Using the wrong size thread can also be an issue, as can failing to properly thread the machine. When threading the machine, it’s important to take your time and make sure the thread is correctly in place.

At times, tension issues could indicate a bigger problem. It could be that the bobbin tension is too high or that the bobbin case is not properly in place. If you’re not sure how to fix these issues, it’s best to seek the help of a professional. They will be able to tell you if the problem is something that can be easily fixed or if there is a bigger underlying issue with the machine.

Finally, if the tension is still off even after adjusting the thread and changing the fabric, it could be time to check the tension disc on the machine. This is a small disc that regulates the tension of the thread. Over time, it can become worn out and needs to be replaced. If you’re not sure how to do this, it’s best to seek the help of a professional.

Check The Needles

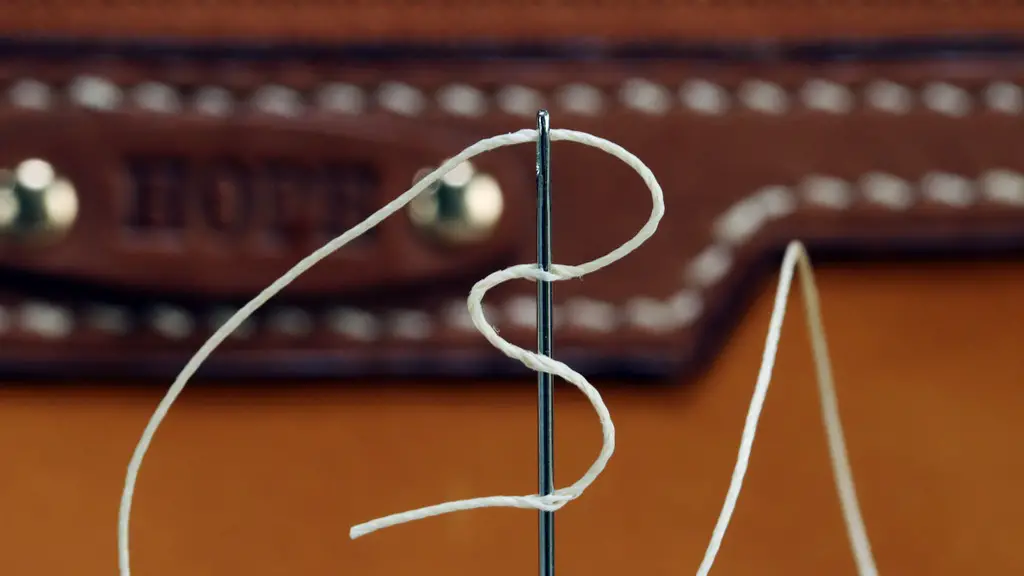

One overlooked factor when it comes to fixing tension issues is the needles you’re using. An old, dull needle can cause stitches to be uneven and tension to be off. So if you’ve been having trouble with tension, it’s a good idea to check the needles. Replace them if needed and make sure you’re using the correct size needle for the fabric you’re working with.

It’s also important to make sure that the needles are not bent or broken, as this can also cause tension issues. If you’re sewing with lightweight fabric, such as silk or chiffon, then you should use a sharp needle, as these fabrics can easily snag and break needles.

So if your sewing machine’s tension is off, the first thing to do is to check the needles. After that, make sure the fabric is properly aligned in the machine and that the thread is the right size and color. If these things don’t work, then you may need to examine the bobbin and the tension disc.

Practice Makes Perfect

When sewing, it’s important to keep practicing and adjusting the tension until you get it just right. It may seem like a daunting task at first, but it gets easier over time. As long as you pay attention to the fabric, thread, needles, and tension disc, you should be able to get the tension just right and enjoy stress-free sewing.

When adjusting the tension, it’s best to start with a low tension setting and gradually increase it until you get the desired tension. Don’t be afraid to experiment, as this is the best way to find the perfect tension setting for different fabrics. Once you’ve found the right tension setting, you can use it as a guide for other projects.

When striving for perfectly balanced tension on your sewing machine, patience and practice are key. It may take some time to work out the kinks and find the perfect tension, but the effort is worth it. When the tension is just right, you’ll be able to enjoy flawless, stress-free sewing.

Adjust Tension According To Fabric Type

The type of fabric you use also has a big effect on the tension of your sewing machine. For thin fabrics, such as silk, you need to have looser tension, while heavier, more dense fabrics like denim require a higher tension setting.

Increasing the tension gradually is the best way to ensure you don’t end up with too tight of a tension, which can cause fraying and damage the fabric. When adjusting the tension, it’s important to pay attention to the stitches and make sure they’re consistently even.

Take your time and adjust the tension according to fabric type. This will ensure that you get the best results possible and that the fabric isn’t damaged by too tight of a tension.

Check Bobbin Tension

The bobbin is an important component of a sewing machine and it also affects the tension. If the bobbin tension is off, the stitches on your project won’t lie flat, which can create uneven tension. So it’s important to make sure the bobbin tension is set correctly when fixing the tension on your machine.

Most sewing machines have an adjustable knob that allows you to easily adjust the bobbin tension. When trying to find the right tension setting, you should start with the lowest setting and gradually increase it until the stitches look even. Make sure to test your stitches on a scrap piece of fabric before working on your project to make sure you have the right tension.

Keeping an eye on your bobbin tension is also important when working on thicker fabrics, as these fabrics tend to be harder on the machine. If the tension is too loose, it can cause skipped stitches, so it’s best to adjust the bobbin frequently.

Inspect The Thread

The tension of your sewing machine can also be affected by the type of thread you’re using. High quality thread is essential for achieving even stitches and balanced tension. If the thread is poor quality, it won’t be as strong and there will be chances of skipped stitches.

Using the wrong size thread can also cause tension issues. The most common thread size is 50, but for some fabrics a finer thread might be needed. When selecting thread, make sure to read the label on the thread and select the right one for the fabric you’re using.

It’s also important to make sure the thread is threaded correctly into the machine. The thread should be pulled through the tension discs before being threaded into the needle. If the thread isn’t threaded correctly, it won’t move through the machine properly and the tension won’t be balanced.

So when tending to the tension on your machine, it’s important to keep in mind the type of fabric, needles, thread and bobbin you’re using. Take your time to make sure everything is balanced, and you’ll be able to enjoy the perfect tension that enables great results.