Introduction

Sewing machines are one of the most popular tools for home crafts and DIY projects. However, like any machine, they can malfunction and cause frustration for the user if they don’t function properly. One of the most common issues is thread jamming, which can cause the sewing machine to stop working. Thread jamming is caused by either the wrong threading of the machine or the wrong type of thread being used. In this article, we’ll look at how to fix thread jam in sewing machines, and how to prevent it from happening in the future.

The Cause of Thread Jamming

Thread jamming can occur when the machine is threaded incorrectly, or when the wrong type of thread is used. Under normal circumstances, threads should slide through the machine with ease. But when the wrong type of thread is used, or when it is clogged with debris or tangled, it can cause the thread to become stuck. If the thread is not properly lubricated or if the tension is set too tight, this can also cause jamming.

Steps to Fix Thread Jamming

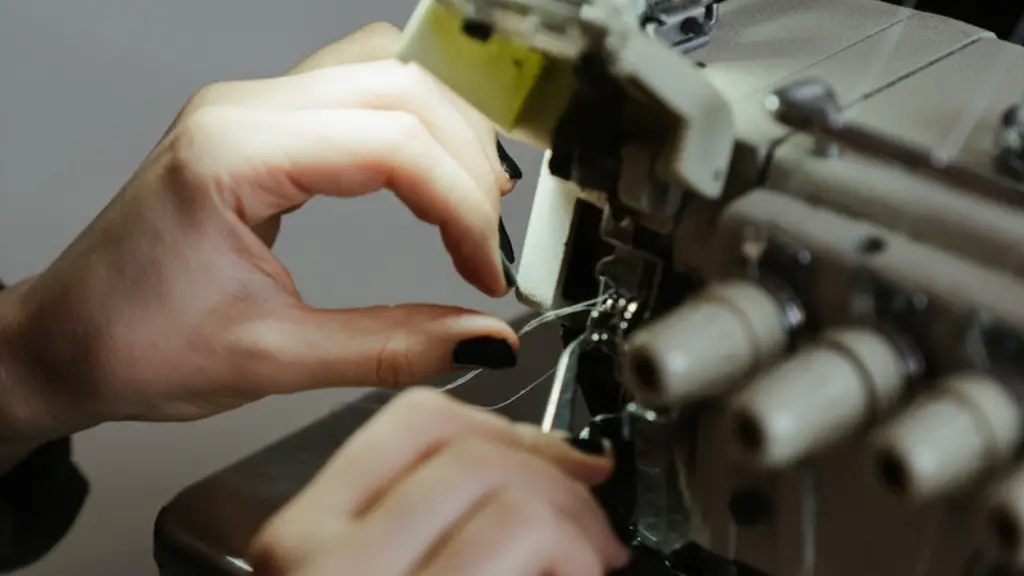

The first step to fixing thread jamming is to check that the thread is properly inserted into the machine and that the tension is set correctly. This can be done by turning the tension knob until the thread slides through the machine smoothly. If the thread is tangled or knotted, it should be cut and restarted.

The second step is to make sure the bobbin is threaded correctly. To do this, turn the machine off and unthread the bobbin. Then thread it again, taking care to ensure it is inserted the correct way. Once the bobbin is threaded correctly, turn the machine back on and ensure the thread is moving properly.

The Proper Use of Thread

In order to prevent thread jamming, the correct type of thread should always be used. High-quality, 100% cotton thread is recommended for most machines, as it provides the best performance and will last the longest. Polyester thread should be avoided, as it is more prone to jamming and can cause damage to the machine over time.

Additionally, it is important to keep the thread clean and lubricated, as this will reduce the risk of jamming. Thread lubricants can be purchased from most fabric stores, and they should be applied to the thread before inserting it into the machine. This will help reduce friction and make it less likely that the thread will become stuck.

Clean the Machine

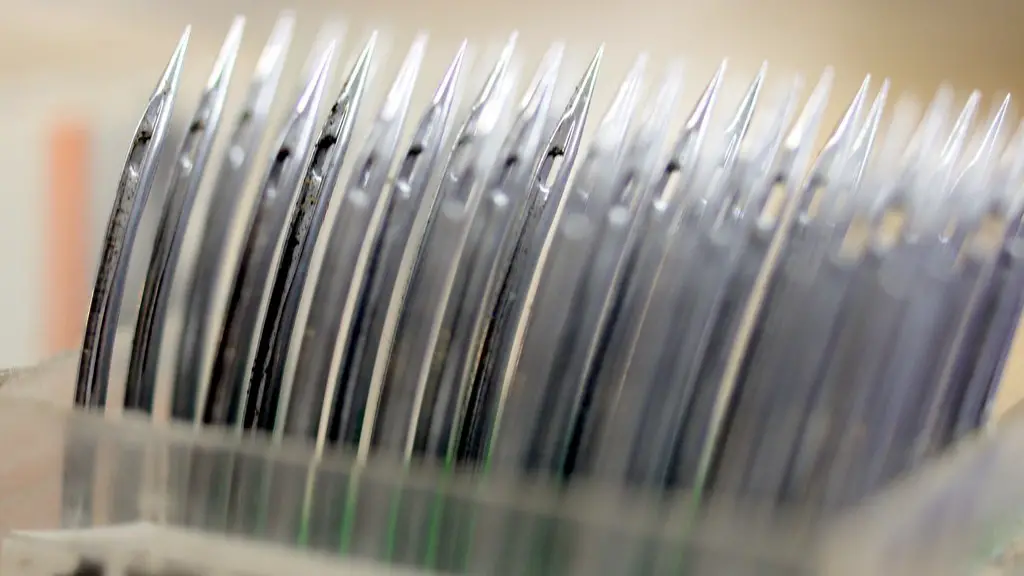

Over time, dust and debris can build up in the machine’s bobbin case and other areas. This can cause the thread to become clogged, leading to jamming. To prevent this from happening, the machine should be cleaned regularly. This can be done with a brush and a damp cloth. Additionally, the needles should be kept clean and free of oil and grease, as this can also cause issues with the thread.

Regular Maintenance

Just as with any machine, regular maintenance is key to ensuring the sewing machine functions properly and lasts as long as possible. This includes regularly checking the tension, ensuring the bobbin is correctly threaded, and making sure the needles are in good condition. Additionally, the machine should be oiled regularly to keep all the parts running smoothly.

Check the Manual

If all else fails, it is best to check the owner’s manual for instructions on how to troubleshoot the issue. Most machines come with detailed instructions on how to diagnose and repair common problems. Following these instructions can help ensure that the machine is functioning properly and that thread jamming is avoided.

Alternative Threading Methods

For more advanced users, there are alternative methods of threading the machine that can help reduce the risk of jamming. These include the “vertical thread approach”, which involves threading the machine from the top instead of from the bottom. This can help reduce the likelihood of the thread becoming stuck or tangled. Additionally, using a weight or a spool holder on the top thread can help maintain the tension and reduce the risk of jamming.

Using the Correct Needles

The type of needles used in sewing machines can also have an effect on the performance of the machine. Different fabrics require different types of needles, and it is important to use the correct type of needle for the fabric being sewn. Needles with a larger eye can also help reduce friction and the risk of jamming.

Correct Sewing Speed and Angles

Another key factor in avoiding thread jamming is ensuring that the machine is set to the proper speed and angles. If the machine is set too fast, it can lead to the thread becoming tangled or stuck. Additionally, the machine should be set at the correct angle to ensure the thread is properly tensioned and can move through the machine without issue.

Testing the Thread Tension

Finally, it is important to regularly test the thread tension to ensure that it is set correctly. This can be done by running a piece of cloth through the machine, and then checking the backside of the cloth to make sure the stitches are even and consistent. If the stitches appear to be uneven, it may be necessary to adjust the thread tension.

Keeping these tips in mind can help reduce the risk of thread jamming in sewing machines, and make the sewing process smoother and more enjoyable. Regularly checking and lubricating the threads, and using the correct needles and speed settings, can help ensure that the machine works properly and that the thread moves smoothly through the machine.