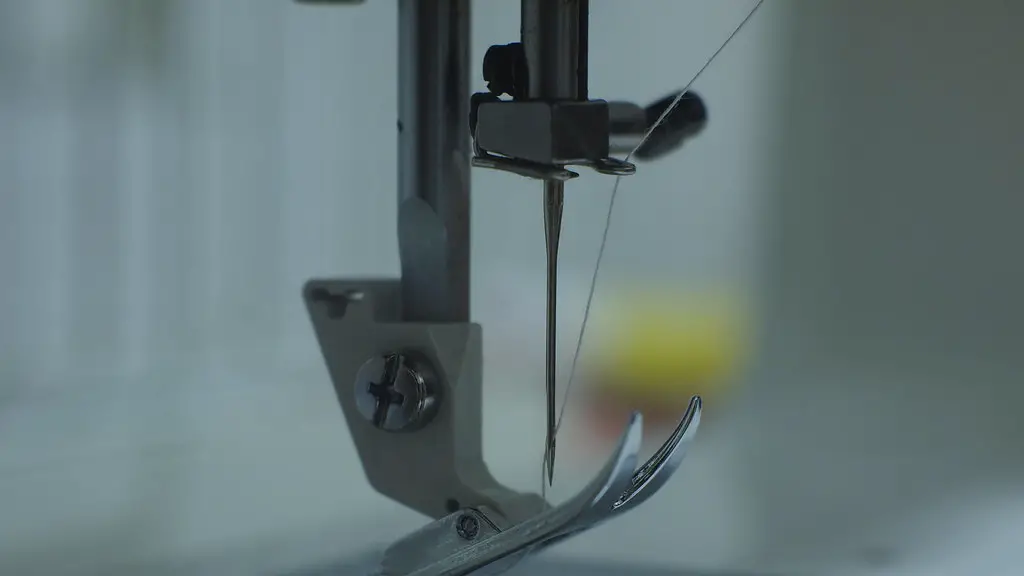

Sewing machines are a wonderful invention that make sewing projects much easier and faster. However, one of the most important parts of a sewing machine is the needle. In order to ensure that your sewing machine is functioning properly, it is important to know how to insert the needle correctly.

To insert a sewing machine needle, first find the needle clamp screw and loosen it. Then, insert the needle so that the flat side is facing the back and the round side is facing up. Next, tighten the needle clamp screw until the needle is secure. Finally, raise the needle to its highest position by turning the handwheel.

Which way does the flat of a needle go in a sewing machine?

A sewing machine needle may look simple, but it actually has several different parts. The shank is the part that seats into your sewing machine; the flat side usually goes towards the back, and the rounded side towards the front. The eye is the hole through which the thread passes; it’s typically located near the tip of the needle. The point is the sharpened end of the needle that pierces the fabric; there are several different types of points available, depending on the type of fabric you’ll be sewing. The groove is a channel that runs along the length of the needle, just below the eye; it helps guide the thread into the eye. Finally, the scarf is a small indentation near the base of the needle that helps prevent the thread from slipping off.

The flat side of the needle should be facing toward the back of the machine. Make sure it is all the way up in the needle clamp, then tighten the needle clamp screw securely.

How do you install a needle

If you’re looking to change your sewing machine needle, follow these steps:

1. Loosen the needle set screw

2. Pull the needle downwards and out of the needle bar

3. Insert a new needle

4. If using an industrial sewing machine, turn the needle so the scarf is on the same side as the hook assembly on the machine

5. Tighten the needle set screw

There’s a screw up here on the top that needs to be turned to the left in order to loosen the clamp that’s holding the needle in place. Once that’s done, you can pull the needle out and replace it with a new one. Make sure to tighten the clamp again before you start sewing.

Is the needle bevel up or down?

There is some debate about the best way to insert an intravenous catheter in children. Some say that it is better to insert the catheter with the bevel facing up, while others say that inserting the catheter with the bevel facing down may be a better option, especially for small or dehydrated children. There is no definitive answer, so it is important to discuss the best option with your child’s healthcare provider before proceeding.

When giving a shot, it is important to place the syringe at a 90-degree angle to the shot site. The needle should be inserted quickly and all the way into the skin.

Do all sewing machine needles have a flat side?

The shank is the part of the needle that is inserted into the machine. The needle shank must be the right shape for your machine. Needles for home sewing machines often have a shank with one flat side and one rounded side for proper positioning. Commercial or industrial needles can have grooved, threaded or round shanks.

Take a new needle with the flat side to the back and insert it in the needle clamp. Once it’s up as high as it will go, twist the needle clamp to the left to secure the needle.

Does the bottom thread go through the needle

The spool thread comes from the top of the machine and goes through the upper thread guide. The bobbin thread is under the needle and goes through the bobbin thread guide. This ensures that the needle is always threaded with the correct thread.

This is how youthread a needle. Hold the thread between your thumb and index fingers and pinch down on the thread between your fingers until you can barely see the tip of the thread between your nails. With your other hand holding the needle, bring the thread and needle eye together.

How do you attach a needle to a thread?

Cut a piece of thread as long as your arm. Then hold the thread close to the end. You do not want to cut the thread too close to the end or it will be difficult to thread the needle. Next, find the end of the thread and thread the needle.

While holding the needle with your left hand, tighten the needle clamp screw by twisting it away from you. Be sure not to over-tighten the screw, as this may damage the needle.

Why wont my needle go back in my sewing machine

If the needle on your sewing machine won’t move when the clutch is engaged, unplug the machine and check the drive belt. Replace the drive belt if it’s broken. If the drive belt is okay, an internal drive gear failure is likely preventing the needle from moving.

If you want to achieve professional results, it is important to change your needle regularly. This may seem like a waste of time and resources, but it is worth it in the end. Waiting for your needle to break or blunt too severely can actually make the process more complicated and less effective.

What holds the needle in place of a sewing machine?

The needle clamp is a very important part of the sewing machine, as it holds the needle in place. Without it, the needle would simply fall out of the machine, making it impossible to sew.

If you are injecting yourself with a needle, it is important to insert the needle into your vein at a 15 to 35 degree angle, with the needle bevel (opening) facing up, and always in the direction of the heart. The more perpendicular the needle is to the injection site, the greater chance you have of sticking the needle through the vein instead of into it.

Conclusion

1. Start by threading the machine with the correct size and type of thread for your project.

2. Raise the needle to its highest position by turning the handwheel toward you.

3. Choose the correct needle for your machine and project.

4. Insert the needle into the needle clamp, making sure that the flat side of the needle is facing to the back.

5. Tighten the needle clamp by turning the screw toward you.

6. Lower the presser foot.

7. Draw up the bobbin thread by turning the handwheel toward you or by pressing the needle down button.

8. Continue sewing!

Once you have chosen the needle you would like to use, inserting it into the sewing machine is a relatively straightforward process. Begin by holding the needle so that the flat side is facing to the back. There is a small screw that you will need to loosen in order to release the needle clamp. Insert the needle into the needle clamp so that the flat side is still facing to the back and retighten the screw. That’s it! You are now ready to start sewing.