1. Overview of Sewing Machine Installation

Installing a sewing machine in a table is no simple task. It requires a certain level of skill, knowledge and preparation to ensure the job is done right. The average sewing enthusiast may need assistance to properly install a sewing machine in a table, as there are certain steps which must be followed in order for the installation to be successful. This article will provide an overview of the process for installing a sewing machine in a table.

2. Preparation

Preparing for the installation process is very important. It is important to ensure the spot where the machine will be placed is perfectly flat. If not, the machine may not be stable enough and may result in it damaging the table. Additionally, the right tools need to be gathered before starting the process. Make sure the drill, screws, and any other tools are ready to use before beginning the installation.

3. Layout

Layout is an important part of the installation process. Knowing where to place the sewing machine in relation to the free arm and any other elements of the table is essential in how the machine functions. This includes making sure the dimensions fit the table, as well as any other safety considerations essential for the machine’s use. By ensuring the layout is accurate, a sewing enthusiast can avoid any potential issues or hazards.

4. Drilling and Securing

The next stage of the process is drilling. This involves drilling holes in the correct locations on the table, after which bolts and screws will be used to secure the sewing machine in place. It is important to ensure that the holes are drilled in the right spot before securing the machine as this will prevent the machine from being tilted or placed at an awkward angle, which can cause damage to the machine and the table.

5. Electrical Connections

Once the sewing machine has been installed, it must then be connected to an electrical outlet. This requires making sure that the power cords are properly connected to the machine and the outlet. It is important to ensure that all connections are properly insulated as this will help to reduce the risk of electrical shock or other damage.

6.Testing and Troubleshooting

Once everything is connected, it is then time to test the machine. Make sure it runs smoothly and there is no issue with the connection to the outlet. If there are any issues, such as the machine not turning on, then it is important to troubleshoot them before using the machine. This involves checking all of the connections as well as any other potential sources of the problem.

7. Cleaning and Maintenance

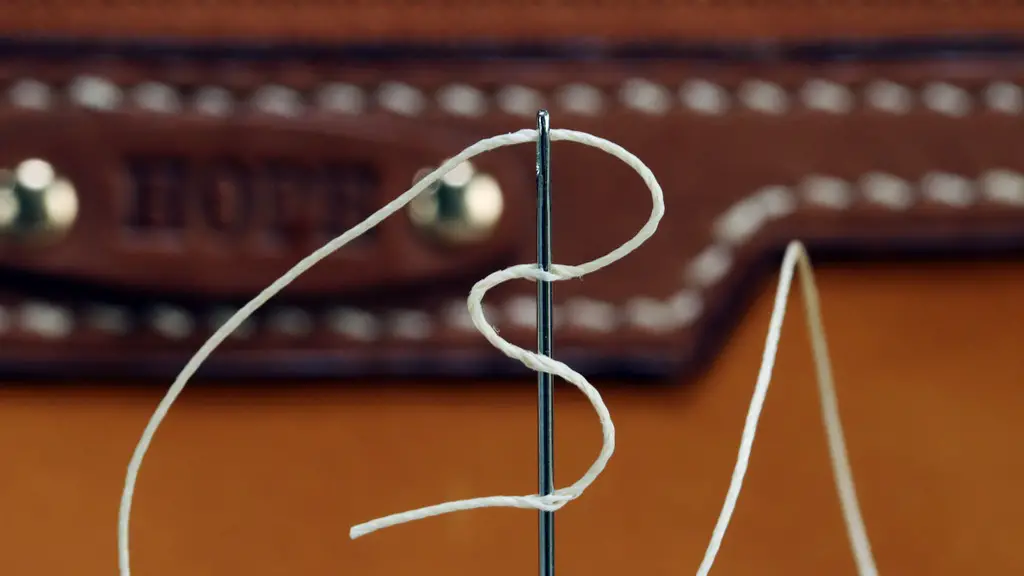

Finally, once the sewing machine is installed, it is important to ensure that it is regularly cleaned and maintained. This will help to keep the machine in proper working order and ensure that it performs at its best. This may involve regularly wiping down the machine, as well as lubricating any moving parts and changing out the needles. It is also important to ensure that the power cords are checked on a regular basis to ensure they are in good condition.

8. Benefits of Installing Sewing Machine In Table

Installing a sewing machine in a table offers many benefits. Firstly, it allows for greater stability and ergonomics for the sewing enthusiast, as the machine will be secured in place and the user can maintain a comfortable posture. Secondly, most tables are equipped with a free arm which allows for easier handling of the fabric when sewing. Finally, having a sewing machine in a table makes transporting the machine much easier, and can make the job of sewing much more enjoyable.

9. Safety and Precautions

As with any electrical equipment, safety must be taken into account when installing a sewing machine in a table. It is important to ensure that all power cords and outlets are properly secured to reduce the risk of electric shock. Additionally, it is important to elevate the machine off the table so that it is not in contact with any sharp edges. This will help to prevent the machine from being scratched or damaged.

10. Sewing Machine Installation Services

Finally, if any sewing enthusiast is apprehensive about installing a sewing machine in a table, or does not feel confident that they can do the job correctly, there are services available that can provide assistance. Many of these services provide professional-grade installation as well as technical support and advice. This is a great solution for those who are in need of assistance in installing their sewing machine in a table.

11. Different Sewing Machines in The Market

The market for sewing machines is vast, and there are myriad models and brands to choose from. Each model of sewing machine has its own unique capabilities, and the selection of a suitable sewing machine should take into consideration the type of project the user will be undertaking. Some machines are designed specifically for embroidery or quilting, while others are built with more basic features and geared towards casual sewing enthusiasts. For an optimal experience, it is important to carefully research each model before making a purchase.

12. Best Practices for Installation and Maintenance

When installing and maintaining a sewing machine, there are certain best practices to follow. These include ensuring the power cords are in proper working order, avoiding exposing the machine to liquids or extreme temperatures, and regularly wiping down and lubricating the parts. It is also important to ensure that the machine is properly secured into the table, as any movement may damage the table or the machine itself. Additionally, it is important to read the users manual and follow any safety instructions before using the machine.

13. Home Based Sewing Business Tips

The advantages of starting a home-based sewing business are that it is relatively low risk, has low overhead costs, and can be a great way to generate extra income. To get started, it is important to carefully plan out your business model, create a budget and build up a portfolio of projects to showcase your skills. Additionally, it is important to take the time to learn about the various tools and materials available so that you can offer the best services to your clients. Hopefully, this article has provided some insight into the process of setting up sewing machines in a table.

14. Professional Sewing Industry Advice

The professionals in the sewing industry have years of experience and knowledge when it comes to setting up and using sewing machines. This includes tips and advice on how to best install a sewing machine in a table. Professionals are also knowledgeable in the types of materials, tools and parts which can be used and how to best maintain and troubleshoot a sewing machine. Additionally, if any modifications or repairs need to be done, a professional service provider can provide the necessary services.

15. Final Words

Installing a sewing machine in a table can be a complex process, and it is important to ensure that the correct steps are taken so that the job is done properly. For those seeking assistance, there are services available which have the knowledge and skill to install a sewing machine in a table. Additionally, professionals in the industry can provide valuable advice and tips on the best practices for installation and maintenance. By researching and understanding the process of installing a sewing machine in a table, one can avoid any potential issues and ensure that the machine functions properly.