Set Up

Loading a bobbin in a Janome sewing machine can seem like a daunting task to a beginner sewer, however it is a skill that is relatively easy to master. Before loading a bobbin, it is important to make sure the thread spool, bobbin and machine are properly set up. To do this, the user should remove the needle plate by loosening the thumb screw and set the thread tension to its highest setting. Unthread the needle, lift the needle bar and slide the shuttle cover off the hook. Detach the needle plate from the hook and place the bobbin in the bobbin case so that it turns counter-clockwise. Using the screwdriver that is provided, turn the tension regulator so it is at its highest setting and slip the bobbin case back on.

Thread the Shuttle

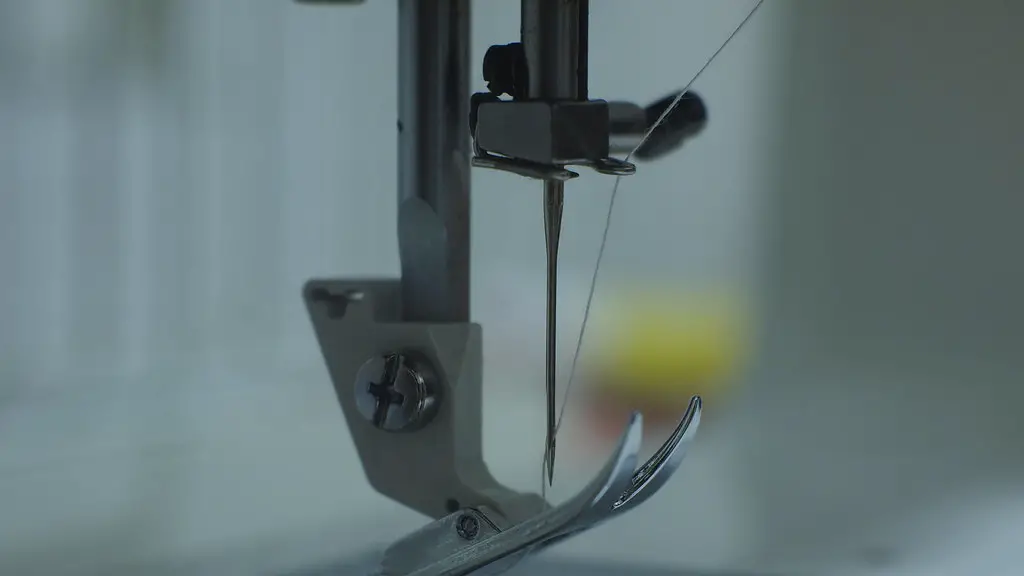

The next step in the process is to thread the shuttle. To do this, the bobbin thread should first be taken from the spool and then fed through the thread guide. This is a small metal guide which is found between the needle and shuttle hook. Pull the thread down and hook it under the latch located just above the hook, then place the shuttle cover back over the hook and loop the thread as shown in the manual.

Thread the Take-Up Lever

Threading the take-up lever is the last step before loading the bobbin. This is done by taking the thread up through the thread guide and then passing it through the lever. The lever can be found next to the thread guide; it is a metal arm that moves up and down as the thread is pulled and wound around the bobbin. Feeding the thread through the lever ensures it is in the correct position for loading the bobbin.

Load the Bobbin

Now that the shuttle, thread and take-up lever have all been threaded, the bobbin can finally be loaded. Before attempting to load the bobbin, loosen the tension regulator so it is no longer at its highest setting and remove the bobbin case by pushing the push lever and turning the case counter-clockwise. Once the case is removed, slide the bobbin onto the bobbin post, so it is facing upright. Make sure that the bobbin post is lined up with the guide marks on the bobbin case, as this will ensure the bobbin is in the correct position.

Start to Wind the Bobbin

To begin loading the bobbin, the user should hold onto the end of the thread and turn the handwheel towards them before pressing down on the start/stop button. This will begin to wind the bobbin and the thread should be kept taut as it is wound. Once the bobbin is loaded, the user should press the start/stop button again to stop winding. Increase the tension regulator just slightly and then slide the shuttle back onto the hook.

Test the Tension

Once the bobbin is loaded, it is important to test the tension before sewing. To do this, the user should thread the machine and disengage the needle plate from the hook. Pull the threads upwards to ensure that the bobbin and needle threads are both taut and even. If the tension is not even, the bobbin should be rewound until the tension is correct. Once the needle and bobbin threads have the same tension, the needle plate should be reattached to the hook.

Check Bobbin Thread is Still Secure

Before beginning to sew, the user should ensure that the bobbin thread is still securely in position. To do this, they should first remove the needle plate from the hook and press down on the reverse button to check if the bobbin is turning. If the bobbin is turning, the user should then press down on the start/stop button to stop the motion and check that the bobbin thread is still in the take-up lever. If the thread has come loose, the user should rethread the take-up lever and then reattach the needle plate to the hook.

Reinsert the Needle Plate

The last step before sewing is to reinsert the needle plate to the machine. This should be done by loosening the thumb screw slightly and then inserting the needle plate back into the hook. The user should then press down on the start/stop button to ensure the bobbin is turning before tightening the thumb screw and beginning to sew.

Preventing Thread Bird’s Nests

One problem that is encountered when loading a bobbin is thread bird’s nests. These occur when the tension regulator is not correctly set and the needle thread pulls the bobbin thread from the shuttle. To prevent this from happening, the user should always ensure the tension regulator is set to the highest setting before loading a bobbin, as this will ensure that the thread is wound securely around the bobbin.

Trim Threads

Before sewing, the user should also trim away any thread tails from the bobbin. This is done to ensure that the thread is not pulled up through the fabric when the user begins to sew, as this could cause unwanted puckering and thread nests. The user should take extra care to trim away any loose threads, as this will help to prevent any problems when sewing.

Troubleshooting Problems

If the tension regulator is set incorrectly or the bobbin is not inserted correctly, it can cause a variety of problems when sewing; such as uneven stitches, thread bird’s nests or skipped stitches. A user can troubleshoot these problems by adjusting the tension regulator, rewinding the bobbin or rethreading the machine. If the problem persists, the user should contact the manufacturer for assistance or further advice.

Develop Good Habits

In order to prevent problems when sewing, it is important for a user to develop good habits when loading a bobbin. This includes observing the manual’s instructions, ensuring the needle plate is properly installed, making sure the tension regulator is set correctly and regularly checking that the machine is threaded correctly. After becoming familiar with the process, regular maintenance will become easier and the user will be able to sew without any problems.

Clean the Bobbin Case

While it is not necessary to clean the bobbin case every time a user changes the bobbin, it should be done regularly. This can be done using a soft brush or cotton swab dipped in rubbing alcohol. This will help to remove any lint or dirt that is present, as both of these can cause problems when sewing. Once the case is clean, the user should then rub a few drops of machine oil onto the shuttle, needle bar, and feed dogs to help keep their sewing machine running smoothly.

Work with the Manual

Each model of Janome sewing machine will have its own instructions on how to load a bobbin. It is important that the user familiarizes themselves with the manual, as this will provide them with detailed instructions on how best to load a bobbin for their specific machine. If the user is having any difficulties, they should refer to the manual or contact the manufacturer for assistance.

Selection of the Right Bobbin

The type of bobbin that is needed will depend on the model of Janome sewing machine. Different models require different sized bobbins, so the user should always check the manual to ensure they are selecting the right bobbin for their machine. For example, some machines may require a class 15J type, while others might require a class 66 bobbin. Different types of bobbins will also require different thread tensions, so it is important to adjust the tension regulator accordingly.

Advice From Sewing Experts

Experienced sewers often advise beginners to practice loading a bobbin several times before attempting any sewing. This is because it is important to become familiar with the process and to be able to quickly and accurately load a bobbin. Also, many experienced sewers recommend that people invest in an automatic bobbin winder, as this can speed up the bobbin loading process and reduce the chances of loading the bobbin incorrectly.

Frequently Asked Questions

Q: How often should I change my bobbin?

A: This will depend on the type of project that you are sewing, however it is generally recommended that you change your bobbin every 5-10 hours of sewing. This will help to prevent the bobbin from becoming loose or tangled, as well as reducing the chances of the needle thread being pulled up by the bobbin thread.

Q: How do I know if my thread tension is correct?

A: This can be tested by pulling the threads up from the needle plate, which should reveal any discrepancies in tension. If the bobbin and needle threads are not taut, the tension regulator should be adjusted until they are both taut and even.

Q: What causes skipped stitches?

A: Skipped stitches are usually caused by an incorrect bobbin thread tension, thread bird’s nests or incorrect needle settings. To fix this problem, the user should check the tension regulator, rethread the machine and adjust the needle settings before sewing.