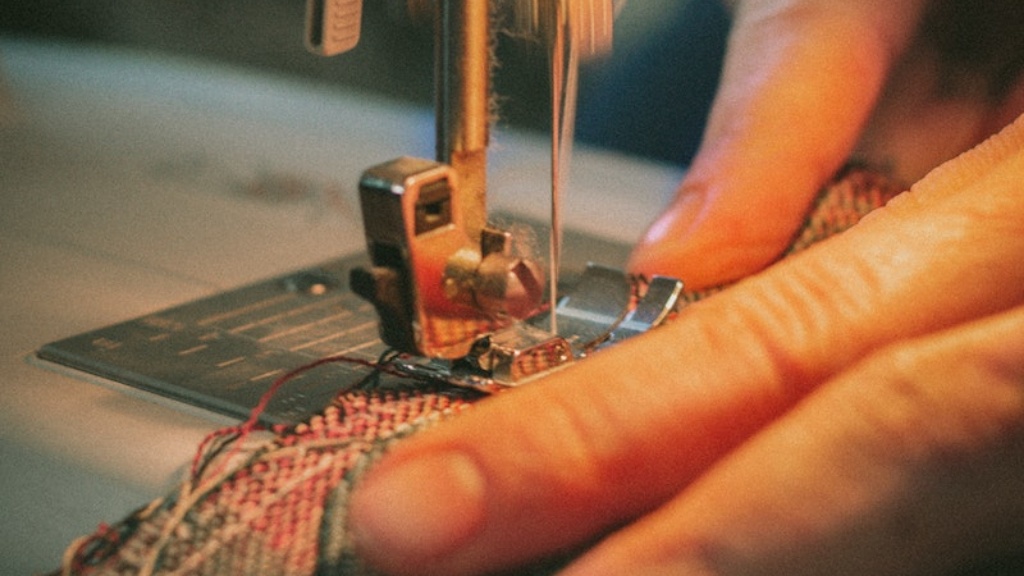

If you’re having trouble with your sewing machine needle hitting the fabric and making it difficult to sew, there are a few things you can do to lower the needle on your machine. First, consult your sewing machine’s manual to see if there are any adjustments you can make to the needle position. If not, you can try raising the presser foot lever to lower the needle. You may also need to raise the throat plate of your machine to give the needle more room to move. These are just a few solutions to try if you’re having trouble sewing with your machine.

To lower the needle on a sewing machine, first locate the needle screw. This is a small screw near the top of the needle shaft. Unscrew the needle screw until the needle lowers to the desired position.

Do you have to lower the needle on a sewing machine?

When you are starting a seam, it is important to lower the needle into the fabric about ½ inches from the beginning of the seam. This will make sure the fabric does not move when you start sewing. Pull the needle and bobbin threads toward the rear to avoid sewing over them.

A disengaged clutch, broken drive belt or internal drive gear failure can prevent the needle from moving. Engage the hand wheel clutch if you have it disengaged for bobbin winding. If the needle won’t move with the clutch engaged, unplug the sewing machine and check the drive belt.

Which part raises and lowers the needle on the sewing machine

The handwheel is an important part of the sewing machine, located on the left side. It is used to raise and lower the needle, and you’ll use it often!

To change the needle on most machines, there is a small wheel that you can hold onto. First, you will need to remove the old needle by unscrewing it from the machine. Next, you will need to insert the new needle into the machine, making sure that it is tight. Once the new needle is in place, you can screw the small wheel back on and begin sewing.

How do you adjust a needle position?

The needle position can be adjusted on a sewing machine by pressing the “+” or “-” keys on the stitch width. This will move the needle to the right or left.

The needle position option on your sewing machine is a great way to ensure that your stitches are sewn exactly where you want them. By using the guides on your presser foot, you can adjust the position of the sewing machine needle to sew your stitches in the precise location that you desire. This is a great feature to use when you are working on a delicate or precise sewing project.

Why won’t my needle go down on my singer?

If you are having trouble with your needle not picking up your bobbin thread, make sure that the bobbin-winding spindle is in the correct position. The spindle should be pushed back to the left for sewing. If it is not in the correct position, the needle will not go down and pick up your bobbin thread.

As you move the slider up to five, you’ll notice the picture changes and the dot is now in the middle of the top row.

How do you unlock the handwheel on a sewing machine

If the handwheel on your sewing machine does not turn or is tight, there are a few things you can try to do to fix the issue. First, try to turn the handwheel toward the back of the machine to see if that will free up the locked handwheel. If not, then check to make sure that the upper thread is not tangled up. If it is, then you will need to turn the machine off and unplug it before you can proceed. Once the machine is unplugged, you can then turn the handwheel toward you once again to see if it is locked. If it is not, then you should be able to proceed with using your machine.

The hand wheel on a sewing machine lets you control the needle manually, moving it up or down as needed. The backstitch lever is used to make the machine sew in reverse, which can be helpful when sewing a seam or hem. The thread spool pin holds the spool of thread for the top thread of the machine in place.

What raises and lowers the needle?

The flywheel (or hand wheel) on a sewing machine is used to lower and raise the needle. When you’re setting up a project to start sewing, you’ll lower the flywheel in order to lower the needle into the fabric.

There are three main parts to a sewing machine that you need to be familiar with in order to thread it correctly. These parts are the hand wheel, the bobbin, and the needle.

The hand wheel is the large wheel on the right side of the machine that you turn in order to sew. To thread the machine, you will need to first turn the hand wheel toward you until the needle is in the highest position.

The bobbin is the small, cylindrical piece of metal that holds the thread. To thread the bobbin, you will need to first insert the thread through the small guide (#8) and then wind it around the bobbin a few times. To do this, you will need to hold the end of the thread with your hand and rotate the bobbin toward you.

The needle is the thin, metal shaft that pierces the fabric and holds the thread. To thread the needle, you will need to first insert the thread through the eye of the needle (#9) and then pull it through until there is a small loop on the other side. You will then need to hold the thread with your hand and pass it through the loop in order to secure it.

How do you drop the needle

The needle drop is a technique used in hip hop deejaying. The DJ sets a record spinning, then drops the stylus on the turntable at the exact point where they want playback to begin without previously cuing up the record. This allows for very precise control over the start of the playback, and can be used to create interesting sound effects.

The presser foot lever is used to raise and lower the presser foot. To raise the presser foot, lift the lever. To lower the presser foot, lower the lever.

How do you lower the needle on a Brother sewing machine?

Turn your machine off unscrew this knob right here. Turn this screw towards you to loosen up the pressure and make sure that this O-ring is seated in this groove right here.

When the Straight or Triple Stretch Stitch is selected, the needle position can be changed from left to right by adjusting the stitch width dial. To set your needle in the right position, set your stitch width dial to 0. To set your needle in the left position, set your stitch width dial to 5. For the normal center position, set your stitch width dial to 2.5.

Warp Up

There is typically a knob or lever on the side of the sewing machine that is used to lower the needle.

With a few simple steps, you can lower the needle on your sewing machine. First, locate the handwheel and turn it clockwise until the needle is in the lowest position. Next, use the lever to lower the presser foot. Finally, lower the feed dogs by flipping the lever or knob. Now you’re ready to sew!