Introduction

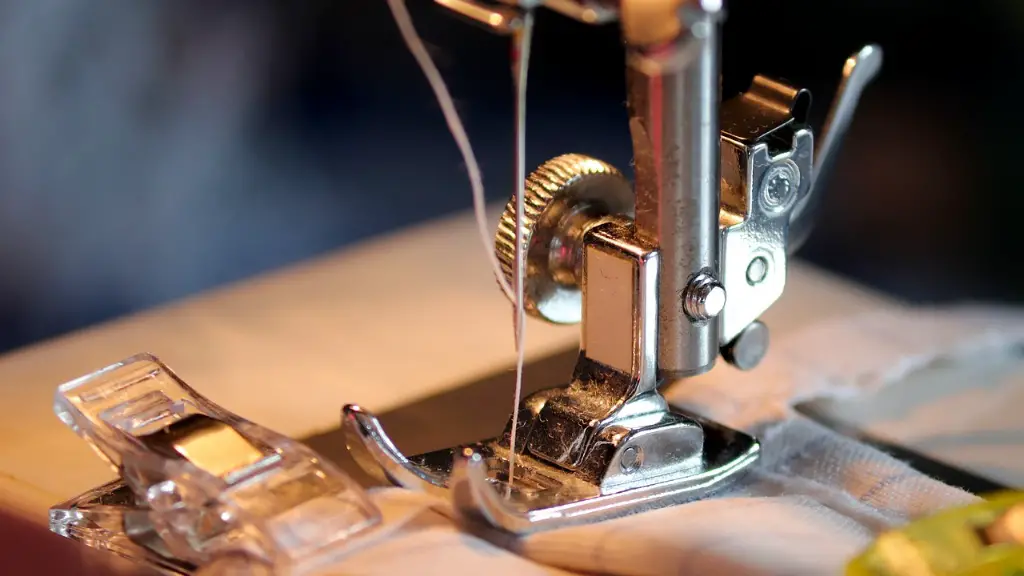

Threading a Brother sewing machine correctly is vital for creating professional-looking and long-lasting stitches. The tension of the upper thread should be properly adjusted, in order for the stitches to be straight and even. Without the correct tension, your thread may break while stitching and will cause wobbly lines. In this article, we’ll provide a step-by-step guide on how to lower thread a Brother sewing machine and provide tips on how to achieve the perfect tension.

Setting up the Threads

The first thing you’ll need to do is select the right thread. Choose a thread that has the best strength and strength-to-weight ratio for your project. Insert the thread spool into the thread spool holder and secure it by winding the upper thread onto the spool pin. Place the thread guide (usually labeled with a “U”) onto the upper thread spool, and slide the thread through the tension disc from the lower thread spool. If you’re using a Brother CS6000i model, you’ll need to slide the thread through the tension disc from the upper thread spool.

Thread Through the Guides

Make sure that the thread is firmly wound around the tension disc before slipping it through the two remaining guides. Pass the thread over the first guide, and under the second, then guide it up and over the hook that is holding the needle thread. On the Brother CS6000i sewing machine, the hook is located on a small disc (lever) below the needle thread hook.

Wrap the Thread Around the Needle

Pass the thread around the needle from back to front, and then place it into the hook that is located directly beneath the needle. On some Brother sewing machines, this hook will be labeled with a “O” or “C.”

Adjusting the Tension

The most important step in threading a Brother sewing machine is adjusting the tension. Adjusting the tension correctly will ensure that you achieve the desired results. The tension should always be lower than the fabric weight. To adjust the tension, use the tension dial, located on the right side of the machine close to the needle plate. Rotate the dial to a lower number to loosen the tension and rotate it to a higher number to increase the tension. Start with the tension at a lower level, and slowly increase it until you obtain the desired results.

Troubleshooting

If you find that the tension is too tight, then the upper thread will not pull the lower thread up. This can result in skipped stitches or a bunching of the fabric. If this is the case, decrease the tension dial to a lower number. If the tension is too loose, then the upper thread will not be securely held by the needle, resulting in uneven stitches and skipped stitches. If this is the case, then increase the tension dial to a higher number.

Testing the Tension

Once you have adjusted the tension, it is important to test it before you start sewing. Stitch a piece of scrap fabric and look at the results. Are the stitches even and straight? If not, readjust the tension dial until the stitch looks even and straight.

Cleaning and Maintenance

It is important to clean and maintain the stitching machine regularly to prevent the buildup of dust, lint, and thread debris. Clean the needle plate, bobbin case, and tension disc with a soft cloth dampened with rubbing alcohol. Use a soft-bristled brush to gently remove lint and threads, then use a lint roller to remove any dust or lint that may have collected on the machine.

Additional Tips

Finally, keep in mind that the tension of a Brother sewing machine is adjustable according to the thickness of the fabric and the type of stitch you are using. Experiment with the tension dial to see what works best for the fabric and type of stitch you are using. Once you have found the correct tension, make sure to use the same tension for similar fabrics and stitches each time.

Different Fabric Types

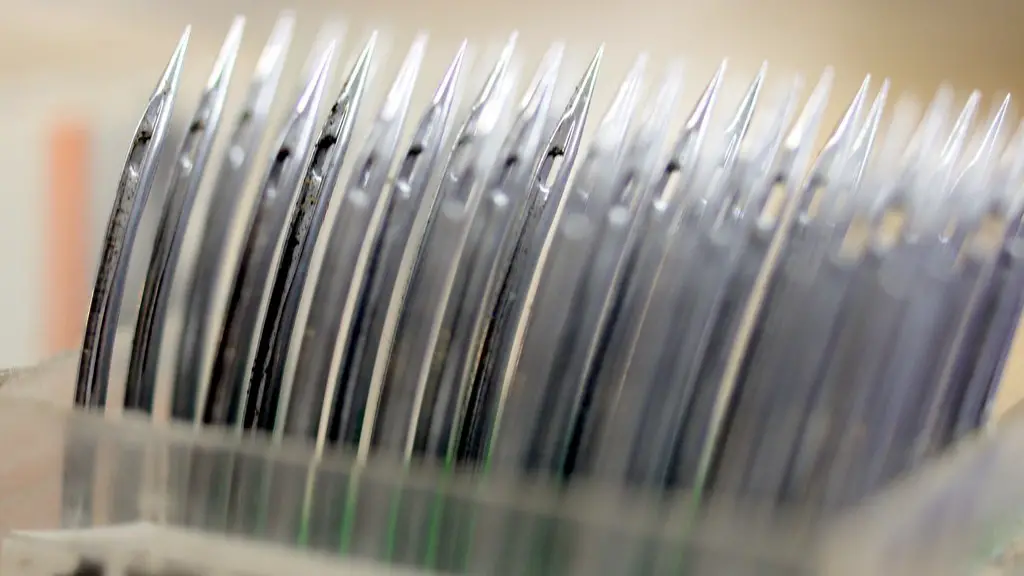

Different types of fabric require different threading techniques, so it is important to have a basic understanding of threading for different fabrics. The type of fabric that you’re using will determine the thread weight, needle size and type of thread that should be used. For example, heavyweight fabrics require heavier thread and a larger needle, while lightweight fabrics require lighter thread and a smaller needle.

Types of Threads

The most common types of threads used in Brother sewing machines are cotton, nylon, and polyester. Each type of thread has different characteristics. Cotton thread is strong and durable and is suitable for sewing most fabrics. Nylon thread is lightweight and has good abrasion resistance. Polyester thread is also lightweight and is ideal for stretch fabrics.

Threading a Serger Machine

Threading a serger machine is different from threading a regular sewing machine. A serger machine will have multiple threads to thread and a series of different thread guides to ensure that the threads are secured in place. To thread a serger machine, start by threading the upper looper first. Begin by threading that thread around the tension disc, and then thread it up through the thread guides and into the upper looper. Then thread the remaining threads (lower looper, top and bottom needles) following the same sequence.

Conclusion

To sum up, threading a Brother sewing machine is a relatively straightforward process, with a few minor steps required to achieve professional-looking results. Make sure to use the right thread, adjust the tension correctly, and clean and maintain the machine regularly. With a bit of practice, you’ll be able to thread your Brother sewing machine with ease.