Husqvarna Viking sewing machines are a popular choice for sewers of all levels. Oiling a Husqvarna Viking sewing machine is an essential part of routine maintenance, but it isn’t always easy to know where to start. Knowing how to oil your machine properly can ensure a longer lifespan for your machine, so it’s important to follow the instructions carefully and use the right kind of oil.

It is important to consult a professional to ensure the oiling process is carried out properly. Using the wrong type of oil or lacking proper knowledge of the oiling process can lead to extensive damage and potential hazard. Sewing machines must be free of dust and lint before they are oiled. Carefully lubricating the moving parts produces a quiet, smooth operation and avoids damage and wear.

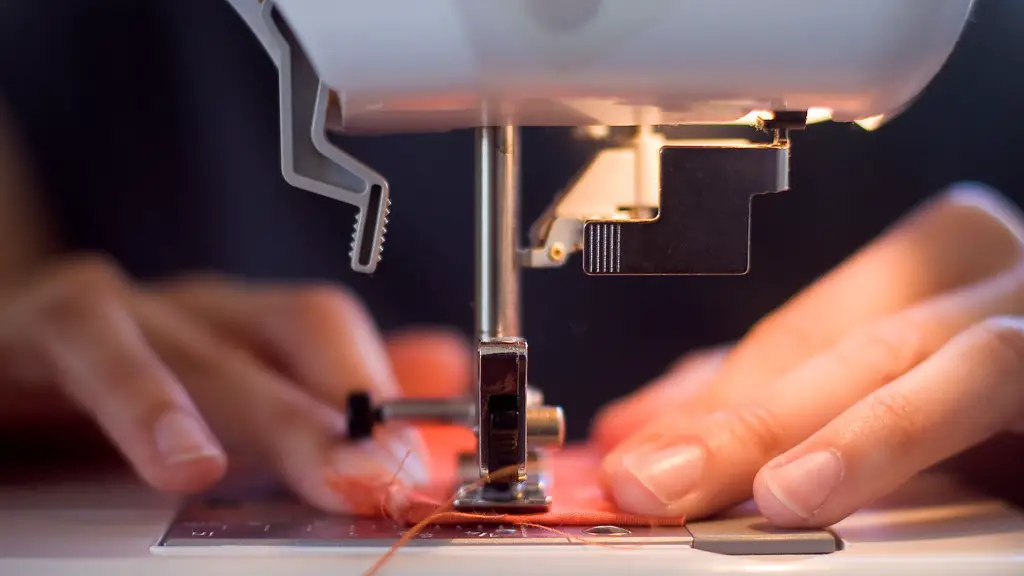

Before oiling a Husqvarna Viking sewing machine, unplug it as a safety measure and carefully remove the whirring and bobbin case. Lift up the needle plate and clean all lint, thread and dust away with a soft brush, such as a paintbrush. Using a lint free cloth, remove the remaining lint and dirt. Vacuuming the inside of the machine is one of the best methods to remove any stubborn, embedded lint.

Using the appropriate oil for your machine is essential. It is best to use a non-detergent sewing machine oil specifically designed for mechanical parts which will prevent clogging. Only a few drops are necessary for each lubrication point, and applying too much can cause clogging and accelerated wear.

Using a long, thin nozzle, place one or two drops of oil on the top, back and sides of the needle bar, under the needle barring lug and the bobbin shuttle, and on the wicking part at the front of the machine. Relying on the user manual can help to find the exact spot of each of these areas to ease the oiling process. Reciprocate the shuttle and slide the thread guide at least three times before continuing to oil the machine.

Gently lubricate the rotary hook of the machine. Add oil sparingly, but take extra care to lubricate the circumference where the bobbin case snaps in and out. Reassemble the machine components before lowering the bobbin case. Place a drop of oil on the very top and the needlebar. Place one drop in each of three spots on the shuttle ways.

Introducing oil below the bobbin case may decrease tension and cause major damage, which can be extensive and costly to repair. Applying one drop of oil to the bobbin race, centre of balance wheel and spindle is enough. After the oiling process is complete, power on the machine and do a few tests to ensure everything is functioning properly. Wipe off the excess oil from the outside of the machine, and post it back together.

Reduce Wear and Tear for Longer-Lasting Machines

A Husqvarna Viking sewing machine is a long-term investment that is important to protect. To maintain a Husqvarna Viking sewing machine in pristine condition, caring and proper use of the machine is essential. Mechanical parts need to be oiled on a regular basis to prevent wear and tear. It is recommendable to perform machine oiling weekly or monthly, depending on how often the machine is used.

Frequent machine oiling keeps moving parts in sync and operation smooth. Oiling the shuttle hook helps to reduce friction and provide clean operation, which is critical for optimal sewing performance. Making sure to use the right kind of machine oil and carefully follow the instructions helps to reduce damage that may result in an expensive visit to the repair shop.

Avoid Damage to Sewing Projects

To make sure lubricants are not transferred to sewing projects, it is essential to choose the right type of oil. Non-detergent, odorless, clear and ZGT-grade mineral oil are the safest types to use as they won’t damage fabric or leave residue. Using oils designed for sewing machine lubrication – such as 3-in-1 oil — is the best way to ensure the oil will not affect delicate fabrics. It is advisable to never use oil not specified for this purpose as it may be flammable or too viscous.

Using a screwdriver to oil the machine is not recommended. This can lead to excessive lubrication in areas not intended for oil, causing a sticky build up and further damage. If a screwdriver is used, the oil may not be distributed properly and the machine may be prone to seizing up, particularly when using tight-toleranced parts.

Troubleshooting After Oiling

After the oiling process is complete, the user should activate the machine to test it. If the machine runs too slowly or not at all, check the oiling process, because it may not have been done correctly. If the machine isn’t working properly after oiling, it is important not to force it. Call a technician who can troubleshoot the issue and correct any mistakes.

Sometimes after oiling, the machine is not running properly. This may be due to a vacuum issue. A machine that is not adequate on suction can cause the machine to run slowly and cause fabric to bunch. Another possible issue may be the belt or pulley. The belt should be lubricated with a belt lubrication spray, and the pulley should be wiped with a lint-free cloth. If the machine is still not running properly after these steps, then it may need to be serviced at a repair shop.

Tips for Effectively Oiling a Sewing Machine

One of the most important tips for oiling a Husqvarna Viking sewing machine is to ensure the machine is completely clean before beginning the oiling process. Remove all lint, dust, and dirt and use an appropriate oil specifically made for machines to avoid damage. A helpful tip is to use a few drops of paper towel to absorb oil if an excess is poured. After oiling, the user should always check the machine to make sure it runs smoothly and lose any remaining residue.

It is also important to recognize when extra oil needs to be added. Signs of needing more oil include thread breakage, needle breakage, skipped stitches, and loud pings. Oiling is an important process to maintain a Husqvarna Viking sewing machine and keep it functioning at the highest level. With this backdrop of information, the sewing enthusiast is adequately informed and ready to oil their own machine.

Necessary Materials for Oiling a Sewing Machine

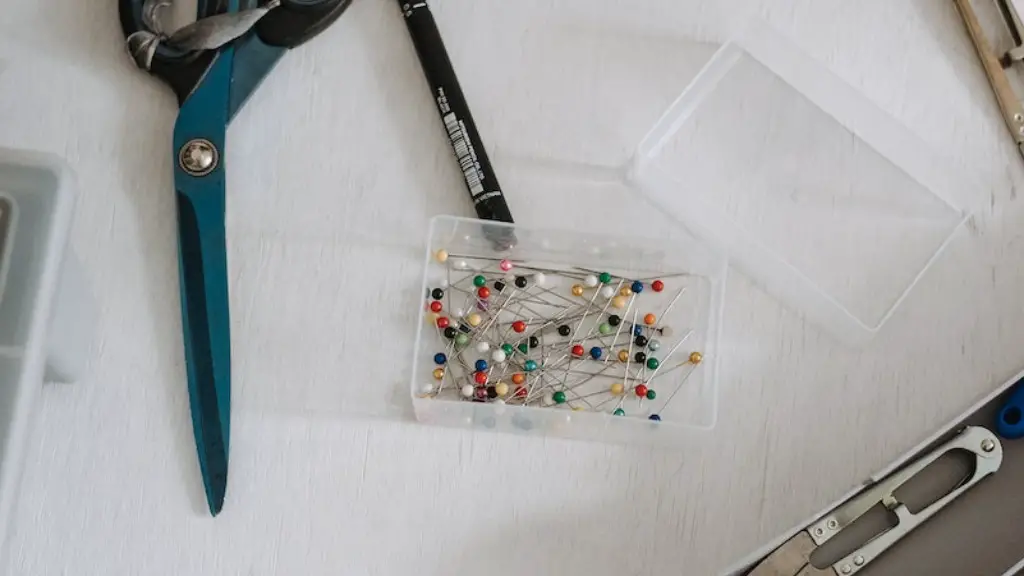

When oiling a Husqvarna Viking sewing machine, it is important to use specific materials for lubrication. An appropriate oil for machines and a lint-free cloth are necessary materials for the oiling process. A plastic bottle with an extended spout or a small syringe is an ideal tool for applying a few drops of oil at each area that requires lubrication. To remove lint, a soft brush and vacuum are essential.

It is also useful to have a complete manual of the machine on hand when oiling. The manual is helpful to find exact spots where oil is necessary and consult any relevant questions. If the machine is prone to dust and lint, it is advisable to keep screen covers in the same place. Lastly, it is necessary to have a technician on hand to troubleshoot any issue that may occur.

Routine Maintenance Regularly

Having a regular maintenance scheme is key to keep a Husqvarna Viking sewing machine running optimally. Professional servicing should be done at least once every two years, but it is advisable to perform routine maintenance more frequently. This includes routinely oiling each area for lubrication, cleaning the machine properly, avoiding wrong tension settings and replacing worn out parts.

Inspecting the machine after every 10 hours of use can help identify any wear and tear and to prevent them from spreading. Having the right materials and user manual on hand helps to make this process easier and more efficient. Taking good care of a Husqvarna Viking sewing machine is essential and requires a deep knowledge of the machine.

Choose Genuine Parts and Accessories

Using genuine parts and accessories for a Husqvarna Viking sewing machine is essential for its long term maintenance and performance. Non-OEM parts can be difficult to fit and may cause damage to the sewing machine. The cost of non-genuine parts may be tempting, but these parts may break prematurely and lead to increased repair and replacement cost.

It is also important not to mix parts from different machines, as the parts must fit correctly and be of the same wear and tear. Choose high-quality fabrics that are soft and lightweight and do not require extra efforts. For knee lifts, plates, presser feet, and other types of accessories it is best to choose genuine parts designed for Husqvarna Viking machines.

Try Before Buying

When purchasing a Husqvarna Viking sewing machine, it is important to test it before buying. Try different stitch types and testing the performance on different fabrics. It’s important to understand each machine’s capabilities to make sure the machine meets the user’s requirements. It’s best to buy a sewing machine from a trusted retailer for a prolonged experience.

Before buying a machine, consider features like portability, power, light control, and thread tensioning capabilities. It’s also important to consider the types of fabrics and threads that the machine can handle. Additionally, consider the size and weight of the machine, as this will affect portability, and whether or not the machine has easy-to- access controls.

Decide if there are any additional features, such as thread-catching, drop feed, and a needle-threading system. It is also essential to look for a basic machine that can use different presser feet and accessories. Finding the right Husqvarna Viking sewing machine with the right features and accessories can help develop a delightful sewing experience.