Understanding a Kenmore 385 Sewing Machine

Kenmore 385 sewing machines are a popular choice among sewers of all levels. They are sturdy, versatile and have an intuitive design. Knowing how to oil your Kenmore 385 can help keep it in top condition and prevent unnecessary costs in replacement parts or repair.

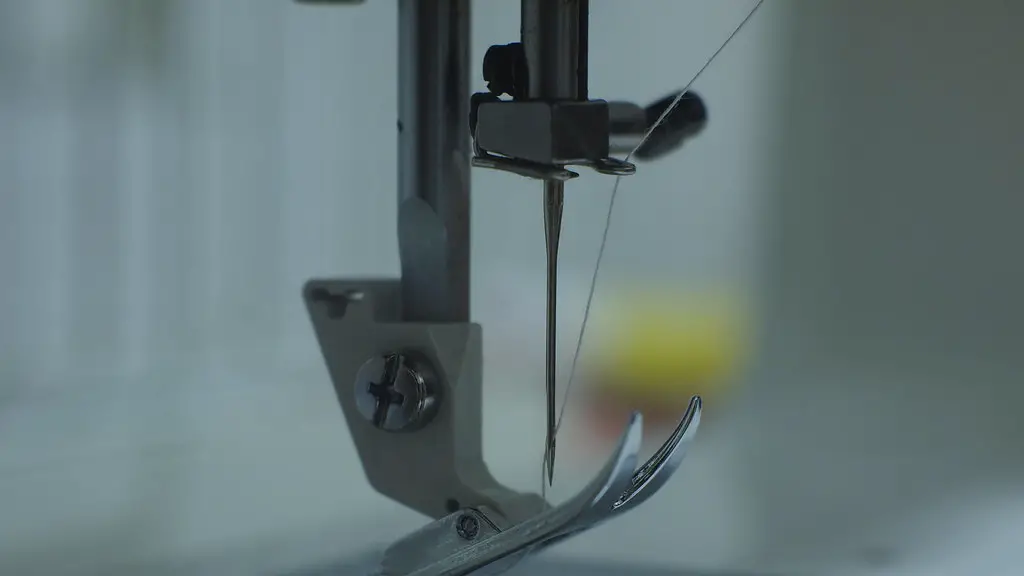

Start with a basic understanding of the machine’s parts. The

Kenmore 385 has a main body, which houses the motor and mechanical parts. The top of the machine is used for attaching fabrics and a belt hook secures the end of the belt that moves the needle into the fabric as it is sewn. On the left side is the bobbin case, where the spool of thread is moved through the machine and the bottom of the machine is used for oiling the moving parts.

Oil is a critical part of the routine maintenance for a Kenmore 385. It helps keep the parts lubricated and functioning. Without proper lubrication, the machine’s parts can grind, freeze and even warp, making it difficult to use the machine. To ensure the longevity of your Kenmore 385, you should oil it regularly.

What Oil Do I Use on a Kenmore 385?

It is important to use the right oil on your Kenmore 385. Sewing machine oil is specifically designed to keep the parts lubricated, prevent corrosion and reduce wear and tear. You can buy sewing machine oil at most sewing supply stores, or you can make your own at home.

To make a homemade sewing machine oil, mix three parts filtered sunflower oil, one part mineral oil and a few drops of lavender, peppermint or eucalyptus essential oil. This combination helps keep your machine lubricated and also reduces odor from the machine.

It’s also important to make sure that you use the correct amount of oil. Too little oil won’t keep the parts lubricated and too much oil can cause a build-up that could damage the machine. Generally, about a teaspoon of oil for every few stitches is the correct amount for properly oiling the machine.

How Do I Oil a Kenmore 385?

When oiling a Kenmore 385, you should start by taking off the belt that runs through the machine. This will give you easy access to the bobbin case and the feed dog. This is the part that moves the fabric through the machine. If the belt is too taut or loses flexibility, this could cause a stitch error.

Once you have access to the bobbin case, you can use a cotton swab or an oil can with a long spout to apply the oil to the bobbin case and the feed dog. Take care not to over-oil, as this could create build-up on the parts and can actually hinder the performance of the machine. Make sure to oil all the parts that move, including the shafts, pulleys and cogs. Once you are finished, you can replace the belt and test the machine.

Additional Tips for Oiling a Kenmore 385

It is also important to note that some parts of the sewing machine should not be oiled. This includes the needle and fabric guides, as too much oil could cause the markings on these parts to fade.

It’s also important to regularly inspect your machine for any signs of wear and tear. If you notice any worn or broken parts, it is best to contact a professional to repair or replace them as soon as possible.

Finally, you should make sure to clean your Kenmore 385 regularly. This will help keep the machine running smoothly and can help prevent any oil build-up.

Frequently Asked Questions About Oiling a Kenmore 385 Sewing Machine

Q: How often should I oil my Kenmore 385?

A: It is recommended to oil your Kenmore 385 about once a month to keep the parts lubricated and functioning properly.

Q: Can I use any kind of oil on my Kenmore 385?

A: It is important to use the correct oil on your Kenmore 385. Sewing machine oil is specifically designed to keep the parts lubricated and reduce wear and tear.

Q: What parts should I oil on my Kenmore 385?

A: You should oil the main body, the belt hook, the bobbin case and the feed dog. Make sure to apply the correct amount of oil, as too much can cause an oil build-up.

How to Keep Your Kenmore 385 Sewing Machine in Peak Performance

To keep your Kenmore 385 in peak performance, it is important to use the correct oil and in the correct quantity. Make sure to regularly inspect your machine for any signs of wear and tear and clean it regularly to prevent any oil build-up. Following these tips can help ensure that your machine stays in top condition for years to come.

Specialized Oils To Use On Kenmore 385 Sewing Machines

When oiling your Kenmore 385, it is important to use the right oil. Sewing machine oil is especially formulated to keep the moving parts lubricated and reduce wear and tear. It is also helpful to add a few drops of essential oils, such as lavender, peppermint or eucalyptus, to help reduce odors from the machine.

You can also purchase specialized oil for Kenmore 385 machines. These oils are specifically formulated to help keep the parts of the machine lubricated and reduce wear and tear. These oils can be more expensive than regular sewing machine oil, but their specialized properties could be worth the investment for keeping your Kenmore 385 in peak condition.

Tools Needed for Oiling a Kenmore 385 Sewing Machine

When oiling a Kenmore 385, there are a few tools that can help make the process easier. For example, an oil can with a long spout can be used to easily apply oil to the moving parts without over-oiling. You may also find it helpful to use cotton swabs to get into tight areas and help keep the oil spread evenly.

In addition, a few other tools may be helpful to have on hand. These include a small brush, needle nose pliers and a screwdriver. Having these tools can help make the oiling process easier and ensure that you are getting the correct amount of oil on the parts.

Maintaining and Upgrading Your Kenmore 385 Sewing Machine

In addition to oiling your Kenmore 385, it is important to regularly maintain and upgrade the sewing machine. Regular maintenance and simple upgrades can help improve the machine’s performance and help keep it running smoothly. Some upgrades, such as changing the needle or replacing worn parts, can be done easily at home.

It is also important to make sure that there are no loose connections or frayed wires in the machine. These issues can easily be overlooked, but they can prevent the machine from running correctly. If there are any loose connections or frayed wires, it is best to contact a professional to repair or replace them.

Lastly, it can be helpful to upgrade the sewing machine’s accessories with higher quality parts. Changing out the needles for high-quality needles can help improve the machine’s performance and keep the stitches uniform.

Conclusion

Oiling a Kenmore 385 is an important part of routine maintenance for the sewing machine. It is crucial to use the correct oil and the correct amount for optimal performance. It is also important to regularly maintain and upgrade the machine to keep it in peak condition and running smoothly. With proper care and maintenance, a Kenmore 385 can last for years to come.