A Singer Heavy Duty Sewing Machine is the easiest way to get started sewing your own material. This robust machine is designed to last you many years and the right oiling can be the key to getting the best performance out of your machine for years to come.

To oil your Singer Heavy Duty Sewing Machine, you will need a few supplies. The first and most important is the lubricant. You can buy this from any sewing store or online. It is also important to have a small flat head screwdriver, some cloth for wiping away any excess oil, and a small oil can. Once you have all of these items, you are ready to begin.

The first step in oiling your Singer Heavy Duty Sewing Machine is to remove the covers from the underside of the machine. You should be able to unscrew the screws with the flathead screwdriver. Once the covers are off, you will be able to see all of the parts that need to be oiled.

You will then want to use the oil and the oil can to gently place some oil on the different parts of the machine. Be sure to use a light amount of pressure on the oil, as too much can clog up your machine. The oil should evenly coat all the parts, but make sure not to over oil any one part, as this could cause damage.

Finally, after the oil is applied, use the cloth to wipe off any excess oil. This will ensure that the oil is evenly distributed and will not cause damage. Once you have finished these steps, you can proceed to reattach the covers to the underside of the machine.

In addition to oiling your Singer Heavy Duty Sewing Machine, it is also important to keep it clean. Dust, dirt, lint, and other debris can quickly accumulate on the various parts of the machine and cause it to wear down and not work as well as it should. Cleaning the machine is important, but it should not be done with any abrasive materials. Use a soft cloth with some all-purpose cleaner and gently wipe the parts of the machine down.

The best way to maintain your Singer Heavy Duty Sewing Machine is to oil it on a regular basis. Depending on the amount of use, you may only need to oil your machine once a month. However, if you are using the machine multiple times a day, then it is recommended to oil it every week. Keeping the oil fresh and the machine clean will ensure that your Singer Heavy Duty Sewing Machine lasts for years to come.

Needle Maintenance

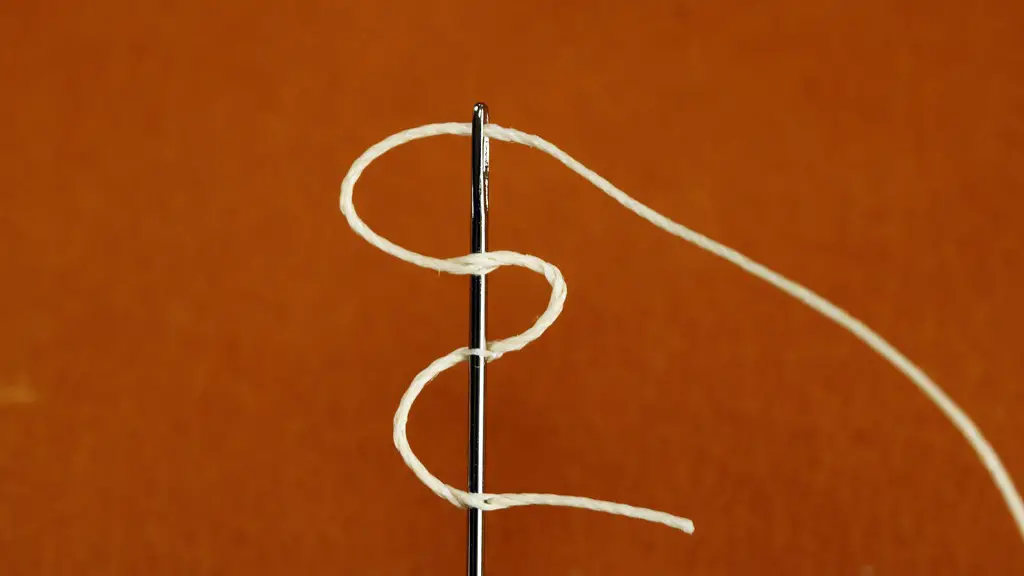

Maintaining the needle on your Singer Heavy Duty Sewing Machine is essential for good performance. The needle should be replaced every few months, depending on how often you use it. It is also important to regularly inspect and clean the needle to ensure that no threading or fibres have become stuck in the eye of the needle.

When changing your needle, make sure you choose one that is designed for the Singer Heavy Duty Sewing Machine. Different models of machines use different types of needles, so it is important to choose the right one for your model. It is also important to use the correct type of needle for the fabric type you are working on. Heavy fabrics require a stronger, heavier needle than lighter fabrics.

In order to ensure that your Singer Heavy Duty Sewing Machine needle lasts as long as possible, it is important to oil it regularly. Use a light oil, such as sewing machine oil that is available from most sewing supplies stores. Carefully place a few drops of oil in the needle and make sure that the oil seeps into all parts of the needle.

Finally, when using the machine, make sure to hold the material taut and not to push the material too hard. This will help to prevent any damage to the needle and fabric. In addition, make sure to unplug the machine before attempting any maintenance or cleaning work.

Motor Maintenance

The motor on your Singer Heavy Duty Sewing Machine is an essential component and should be cared for regularly in order to keep it in top condition. To start, it is important to keep the motor clean. This can be done by carefully wiping it down with a cloth and a light all-purpose cleaner. It is important to keep the motor free of dust and debris, as this can create wear and tear on the motor and reduce its life.

It is also important to oil the motor on a regular basis. You can use a light oil for this, such as sewing machine oil. Place a few drops of oil on the motor and make sure that you spread it around evenly. However, make sure not to use too much oil or you may damage the motor.

It is also important to inspect your motor regularly. This should be done every few months, or whenever you notice that the motor is not running as efficiently as it once did. Carefully inspect all parts of the motor, such as the belt and the motor shaft, for any signs of wear or damage. If you notice any issues, it is best to take the machine to a professional who can properly repair the motor.

Finally, it is important to make sure that the machine is unplugged before attempting any maintenance or repair work. Oiling or repairing a machine that is plugged in can create a dangerous situation and potentially damage the machine.

Troubleshooting

As with any machine, there may be times when your Singer Heavy Duty Sewing Machine does not run as smoothly as it should. Knowing some basic troubleshooting techniques can help you identify any potential problems and make sure that your machine is running efficiently.

One common issue is thread breakage. This can happen for several reasons, such as the tension being too high or the thread being too weak for the fabric. If you are experiencing thread breakage, first make sure that the thread is the correct type for the fabric that you are working on. Also make sure that the tension is set properly and that the thread is free of knots or tangles.

If the machine is making strange noises or is not running as smoothly as it should, the belt may need some adjustment. Make sure that the belt is properly tensioned and that it is free of wear and tear. If the belt is worn, it may need to be replaced.

Finally, if your machine is skipping stitches or having trouble with the tension, you may need to adjust the bobbin tension. This is a simple process that can be done with a small screwdriver. However, it is important to be careful when doing this, as too much tension can damage your machine.

Storage and Care

If you are not using your Singer Heavy Duty Sewing Machine, it is important to store it properly in order to keep it in good condition. Clean the machine thoroughly before storing it and make sure to wipe down the motor, needle and all other parts of the machine. Once the machine is clean, wrap it in a protective cloth and place it in a cool, dry environment.

It is also important to keep the machine dust-free. Investing in a dust cover is a great way to keep dust and debris from accumulating on the machine. This will help to keep your machine in top condition and ensure that it will last for many years to come.

Finally, in order to get the best performance from your Singer Heavy Duty Sewing Machine, it is important to keep it oiled and the motor and needle in good condition. Oiling the machine and inspecting the motor and needle regularly will help to ensure that your machine is running smoothly and efficiently.