Preparing your Elna Sewing Machine for Oiling

Elna sewing machines are precision instruments, so it is important to properly oil them in order to keep them running smoothly and effectively. Oiling can extend the life of your sewing machine and minimize wear and tear on internal parts. With the right supplies and proper technique, the process of oiling your Elna sewing machine is relatively straightforward.

Start by gathering the supplies you need. First and foremost, you will need oil specifically designed for sewing machines. Regular motor oil should never be used since it can damage the machine and interfere with functionality. You will also need a clean cloth, scissors, tweezers, and toothpicks.

Clearing away old Lint and Thread Particles

Take the machine apart by unscrewing the bobbin cover, then separate the bottom and top feed dogs to reveal the interior of the machine. Using the tweezers, begin plucking any gathered lint or thread particles from the machine. Also remove any stray thread from the feed dogs at this time.

Clean the machine with a cloth dampened with a tiny amount of water. Never use solvents or any other cleaning solutions as this can damage the fabric or make the plastic housing crack. Once the machine is clean, dry it with a clean cloth.

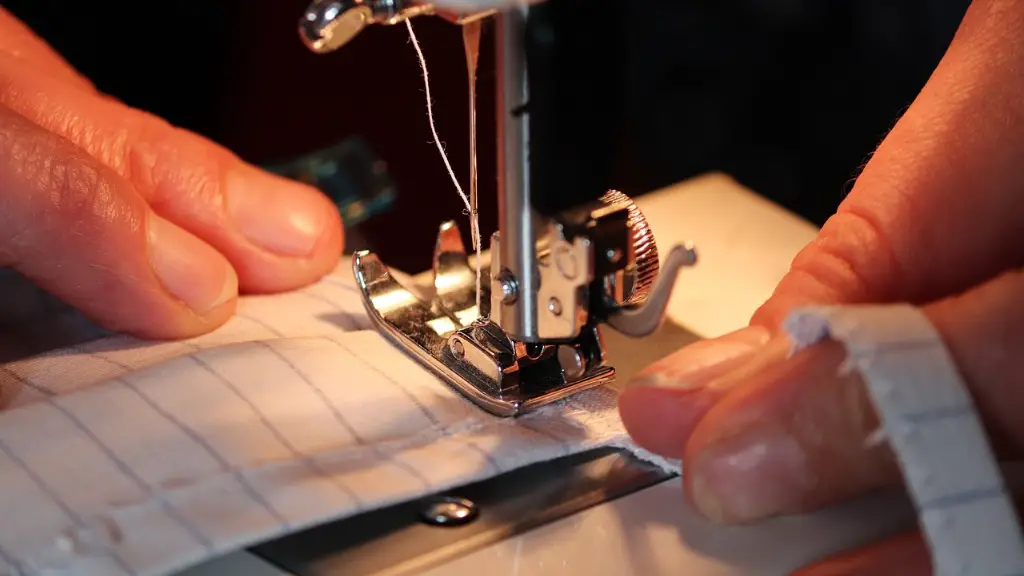

Application of Oiling

To ensure proper application of oil, this should only ever be done when the machine is completely cool. Insert a few drops of oil at the tip of a toothpick into the points indicated by Elna, located in the lower section of the bobbin. As the toothpick moves through the machine, spread the oil with it, taking great care to avoid the fabric. While lubricating, tilt the machine around a little to allow the oil to spread better.

Exit holes are located on the rear of the machine where the oil accumulates. These should also be oiled. Once the inside parts have been lubricated this way, use a cotton swab moistened with a couple drops of oil to lubricate the hooks collecting excess oils as you go. Apply a drop or two of oil in each of the five places listed in the instruction manual. Allow the oil to sit for up to 10 minutes before you go on to the next step of reassembly.

Reassemble the Machine

Once the oil is fully spread within the machine, you can start to put it back together. Begin reassembly with the feed dogs by clipping them in place. Once the lower feed is put back in its place, you can put the needle plate in its slot. Close the bobbin cover and tighten the screws. You also have to rethread the entire machine. If a clean cloth was used to wipe out the machine and remove dust, these steps should be fast and easy.

Check for Proper Fitting and Operation

Once everything is put back in place, attach a new piece of fabric to the machine and test it out. Start with a simple straight stitch to verify that the machine runs smoothly. If it jams frequently, then you may have reassembled the machine improperly. If the machine is operating as it should, then congratulations! Your Elna sewing machine is now properly oiled and ready to go.

Cleaning and Storing the Sewing Machine

After you have oiled and tested your Elna sewing machine, you will want to keep it clean and stored properly in between uses. Be sure to keep the machine clean and free of lint and any other debris. Take care to protect it from moisture when stored, and refer to the Elna manual for any special instructions.

You can also consider purchasing special cleaners and lubricants to give your machine a more thorough cleaning, as well as storage cases specifically designed for sewing machines. Most Elna dealers can point you in the direction of products specifically designed for your machine.

Oiling Frequency for Elna Sewing Machines

It is widely recommended that you oil your Elna sewing machine every six months or so, and after any large sewing projects. Doing so will ensure that your machine stays in good working condition over the long haul— protecting your investment and keeping your projects running smoothly.

Oil Alternative for Elna Sewing Machines

Though traditional oil is the preferred and recommended method for lubricating sewing machines, there are alternatives available. Always use silicone oil and avoid synthetic or petroleum oils as they may leave residue or interfere with fabric. Silicone oil is available in aerosol spray canisters and is simple to apply directly to the machine, making it an ideal alternative to canned oil.

The Benefits of Oiling an Elna Sewing Machine

Oiling your Elna sewing machine is a straightforward process that can bring a number of substantial benefits. Oiling your machine regularly will help decrease the chances of jams and friction, increasing the sewing speed, as well as extending the life of the machine. Proper oiling can also reduce noise, vibration and the amount of heat generated by the machine when in use. So make sure to oil your Elna sewing machine regularly for maximum performance and longevity.

Precautions for Oiling an Elna Sewing Machine

When oiling your Elna sewing machine, be sure to take all necessary precautions to ensure the best results. Always use a clean cloth when cleaning your machine, and use oil specifically designed for sewing machines so that it does not cause any damage. Be sure to read the Elna manual before oiling to know exactly where and how much oil to use, so that your machine remains well-oiled and in top condition.