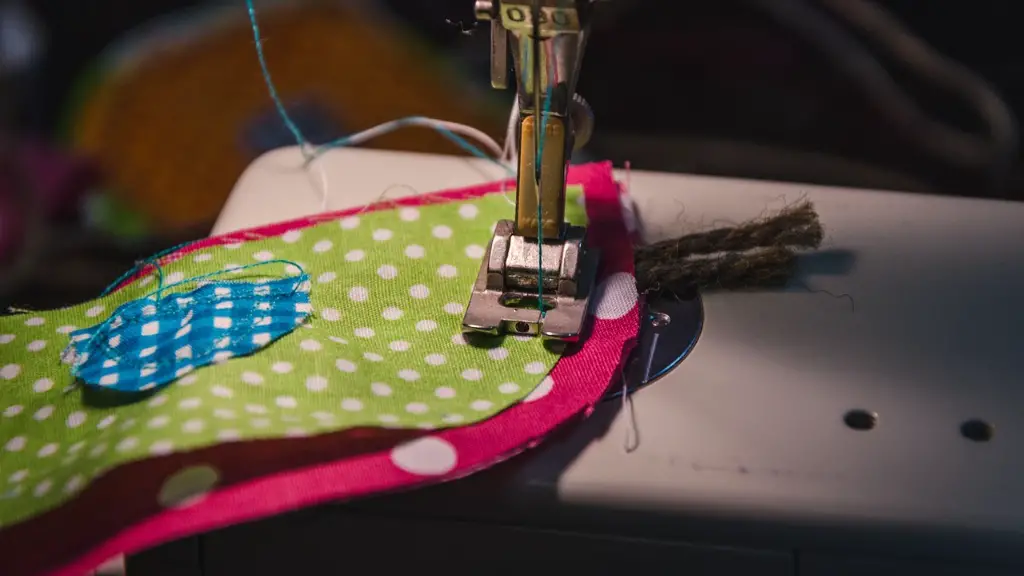

A sewing machine is a machine used to assemble fabric and other materials with thread. It is an incredibly useful tool, especially for those who are very involved with sewing, but the process of attaching thread to the sewing machine can be slightly intimidating for the beginner. Thankfully, it’s not as difficult as it may seem, and you can have your thread attached and ready to go in a matter of minutes. Here’s a step-by-step guide to properly placing thread in your sewing machine.

Step One: Gather the Necessary Materials

To thread a sewing machine, you will need a spool of thread, a pair of scissors, and the thread guide, which is usually found on the body of the sewing machine. You will also need the thread’s spool pin, which is the metal or plastic object that the spool of thread sits upon.

Step Two: Examining the Thread Guide

Take your time to examine the thread guide. Most sewing machines use the same type of thread guide, but some may vary slightly. Start by noticing the thread guide itself, which is usually four circles. The two top circles should look like two eyes that you’re threading into, and the two bottom circles act as a clamp for the thread.

Step Three: Threading the Upper Part of the Thread Guide

Take your spool of thread and place its spool pin into the slots of the thread guide. After that, take the thread and pull it through the top two circles until it looks like a figure eight. Once you have created this figure eight, loop the thread around the left-hand side of the upper part of the thread guide, ensuring that it is sitting near the top two circles. Now, you should be able to pull the thread through the top two circles until it is secure.

Step Four: Threading the Lower Part of the Thread Guide

Take the end of the thread and loop it through the bottom two circles of the thread guide. After that, pull the thread through the bottom circles until it is secured. Take the thread and wrap it around the left-hand side of the lower part of the thread guide. Make sure that the thread is looped around the left-hand side so that it is near the bottom circles of the thread guide.

Step Five: Check the Tension

Once you have secured the thread in the thread guide, it is essential to check the tension. To do this, simply pull the thread taut between the top and bottom circles of the thread guide. You will then be able to see if the thread is tight enough or too tight, and adjust it accordingly. Once you are content with the tension, you can tie a knot at the end of the thread to keep it in place.

Step Six: Insert Thread Into Needle

To insert the thread into the needle, you will first need to take the end of the thread and loop it through the slot in the needle. Make sure that you do not force the thread, as this could damage your needle. Once the thread is securely in the needle, you can then begin to sew.

Step Seven: Secure the Thread to the Needle

To secure the thread to the needle, it is best to tie a knot at the end of the thread. This will ensure that the thread stays in the needle, and that your stitches do not come undone. Take the thread and tie a simple overhand knot at the end, making sure that it is tight enough that it will not come undone while you are sewing.

Troubleshooting Tip

If you find that the thread is difficult to thread through the needle, it may be because the needle is damaged. If this is the case, it is best to replace the needle as soon as possible, as a damaged needle can cause a range of issues with the quality of the stitches.

Step Eight: Start Sewing

Once you have completed all of the steps above, you can now start sewing. It is important to test the tension of the thread both before and after every stitch. This will ensure that the thread is correctly tensioned and that your stitches are looking as they should. Sewing can be a very enjoyable and rewarding experience, so it is important to make sure that you get the basics right.

Using A Bobbin

If you are using a sewing machine with a bobbin, you will need to thread the bobbin as well. Start by unwinding the spool of thread and threading it through the bobbin’s thread guide. Once the thread has been inserted into the thread guide, place the bobbin in the bobbin case and pull the thread so that it is securely in place.

Additional Threading Tips

Threading your machine correctly and properly will ensure that you get the best possible results from your sewing project. Here are a few additional tips to keep in mind:

- Make sure that the thread is wound loosely around the spool as tight threads can cause knotting and tangling.

- Always use high-quality thread. Low-quality thread may be cheaper, but it will not produce the same results.

- Keep the thread and spool stored away from direct sunlight or sources of heat.

- Check the tension of the thread after every stitch to ensure that it is correct.

Preparing the Thread on the Sewing Machine

Once you have gathered all of the necessary supplies, you can begin to thread the sewing machine. Start by affixing the spool to the spool pin, and then threading the top part of the thread guide. Make sure that you wrap the thread tightly around the thread guide, as this will help to prevent knotting and tangling. After that, you can thread the thread through the needle. Take care to make sure that the thread is not too loose or too tight, as this will affect the quality of the stitches.

Tension Adjustment on the Sewing Machine

Threading the sewing machine correctly is essential, but the tension of the thread is just as important. To make sure that the tension is correct, it is best to adjust it before each stitch. Most sewing machines have a tension knob located either on the side or the front, and this knob can be used to adjust the tension. Make sure to test the tension after each adjustment to make sure it will produce the desired outcome.

Correct Thread Storage and Handling

When it comes to thread, it is essential to make sure that it is stored and handled correctly. This includes ensuring that it is kept away from direct sunlight and sources of heat, as too much warmth can cause the thread to become brittle and unravel. Additionally, it is important to ensure that the thread is wound loosely around the spool, as tight winding can cause the thread to tangle and knot.