The Necessary Items Needed

Before learning how to put a foot on the sewing machine, it is important to understand the items that are required. This includes the foot, screwdriver, and needles. The foot is usually packaged in a plastic holder with a screwdriver and is used for attaching the fabric to the needle. The screwdriver is used for tightening the foot on the sewing machine. Additionally, needles are essential for stitching the fabric. If the needle’s size is incorrect for the fabric, the stitch will not be even and uniform.

Threads

Threading the sewing machine is the second step in the process. The threads must be fed through the eye of the needle and the tension of the thread should remain consistent. To ensure a proper result, the thread should be compatible with the needle. It is important to note that the thread’s color should match the color of the fabric for a better result.

Positioning the Sewing Machine

The next step in putting the foot on the sewing machine is positioning the machine. Positioning the machine is essential as it helps ensure that the stitches will be even and uniform. The sewing machine should be placed at a comfortable height and the fabric must be positioned so that it does not move when the foot is in use. In addition, the fabric should be placed flat on the machine’s surface for the best result.

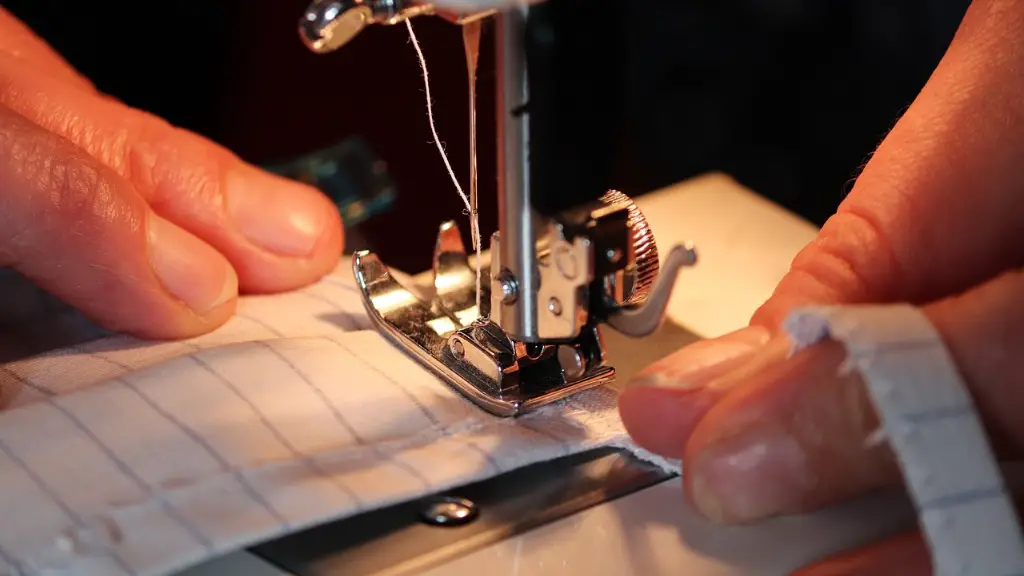

Attaching the Foot

To attach the foot on the sewing machine, the user should first insert the small screwdriver into the hole near the hub of the foot. Then, the user should apply slight pressure to the small screwdriver at the same time turning the hub of the foot. This will lock the foot onto the stitching machine. Once the foot is attached, the user should take note of the specific type of foot being used as different feet are used for different tasks.

Testing Out the Foot

Once the foot is attached, it is important to test the foot prior to beginning work. To do so, the user should stitch a few lines on a scrap piece of fabric. If the stitches are straight and even, then the foot is attached properly. However, if the stitches are not even, the needle may need to be adjusted to a different size or the thread tension needs to be adjusted.

Adjusting the Needle

If the stitches are not even, then the needle may need to be adjusted. To adjust the needle, the user should first locate the screw on the side of the needle. Then, the user should turn the screw counterclockwise until the needle is at the desired height. Additionally, the user should check to see if the needle is not bent or chipped as this can affect the stitching process.

Adjusting the Thread Tension

If the stitches are still not even, then the thread tension needs to be adjusted. To adjust the thread tension, the user should locate the tension knob on the side of the machine. Then, they should turn the knob counterclockwise until the desired amount of tension is reached. It is important to note that the tension should be even to ensure proper stitching and it is better to have less tension rather than more tension.

Changing the Needle

When it is time to change the needle, the user should turn the hand wheel away from the needle to loosen it. Then, the user should unscrew the needle by turning it counterclockwise. Once the needle is unscrewed, the user should insert a new needle of the desired size, making sure to tighten it clockwise. Finally, the user should turn the hand wheel back towards the needle and ensure that the needle is secure.

Cleaning the Sewing Machine

After the foot is attached and the needle and thread tension are adjusted, it is important to clean the sewing machine. Cleaning the sewing machine is important as it prevents dirt, dust, and debris from getting into the machine and affecting its performance. A soft cloth should be used to wipe down the machine, paying close attention to the area around the needle, foot, and thread guides.

Protecting the Machine

The final step in the process is protecting the machine. This can be done by covering the machine when it is not in use. The cover should be of a quality material to ensure that the machine is well protected. Additionally, the machine should be placed away from sources of moisture and sunlight in order to ensure its longevity.

Preventing Thread Knottings

Thread knottings can occur when the thread is tangled or if there is not enough tension. To prevent thread knottings, the user should ensure that the thread is well fed onto the spool and pass through the thread guides. Additionally, the user should make sure that the thread is not too tight or too loose as this can cause thread knottings.

Ensuring Straight Stitches

To ensure that the stitches are straight, the user should make sure that the needle is in the correct position and the thread tension is correct. Additionally, the user should ensure that the fabric is flat on the sewing machine’s surface as this can affect the stitch. If the fabric is not flat, then the stitches may not be even.

Learning The Commercial Sewing Machine Settings

For commercial sewers, it is important to learn the different sewing machine settings as each machine has different settings. It is important to take note of the settings, such as the stitch length, needle position, and foot presser. Additionally, the user should consult the instruction manual to learn how to properly adjust the settings.

Troubleshooting the Machine

When the sewing machine is not working properly or is not producing the desired results, it is important to troubleshoot the machine. To do so, the user should first locate the source of the problem. This can involve examining the joints, the needle, and the thread. Additionally, it is important to consult the instruction manual in order to find possible solutions.

Using The Foot Control Pedal

When using the foot control pedal, it is important to ensure that the user’s foot is positioned properly. The foot should not be too close to the wheel as this can cause the foot pedal to jam. Additionally, the user should always be aware of the needle when pressing the foot pedal as the needle could become injured.

Learning Specialized Sewing Techniques

Depending on the type of project, the user may need to learn specialized sewing techniques. For example, learning to sew a zipper or a buttonhole can be a challenging task. To do so, the user should consult a book, watch videos, and taking classes to further progress in their skills. Additionally, the user should always practice and perfect the technique with scrap pieces of fabric.

Maintaining the Machine

In order to ensure the longevity of the sewing machine, it is important to maintain the machine regularly. This involves oiling and cleaning the machine on a regular basis. Additionally, the user should inspect the machine periodically for worn or broken parts. If any issues are found, then the user should consult the manufacturer or a professional to get the machine fixed.