Most people nowadays have access to modern day sewing machines that are relatively easy to maintain and operate. It is no wonder why those who love to sew have begun to take up this fun hobby. Although there are many aspects to learn, the most important part is knowing how to put a needle in a sewing machine – an essential part of the process that ensures that the machine runs smoothly and your projects can be completed with ease.

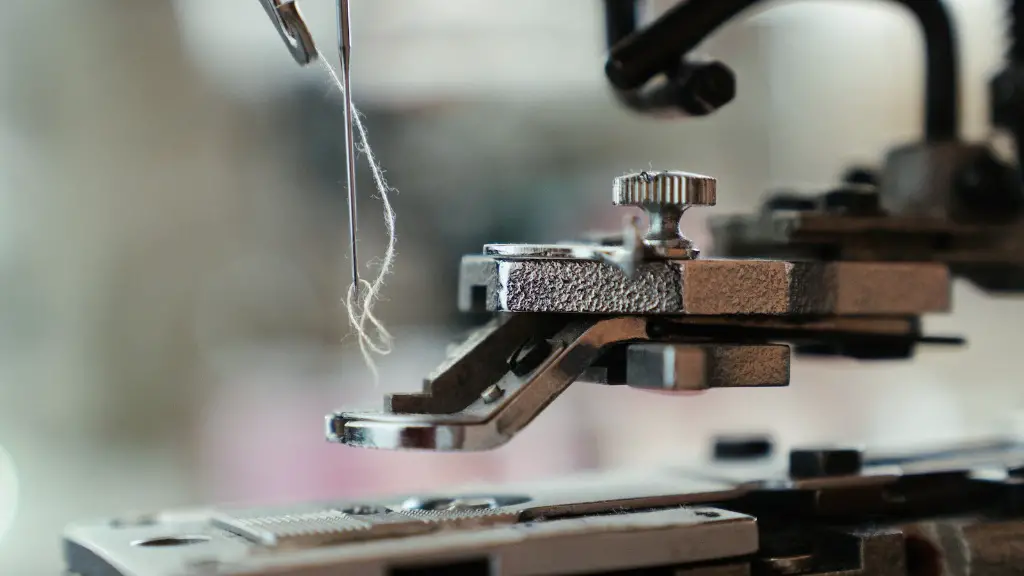

In order to ensure that the needle is inserted correctly in the sewing machine, one should first familiarize themselves with the parts of the machine and the needle itself. The needle has a flat side and a rounder, thicker side with a tiny groove running the length of it. The long arm of the needle is situated at the base which should be inserted first into the slot available on the machine.

If one is unsure of how to proceed with inserting the needle, one should refer to their sewing machine’s instruction manual to get started. First, turn off and unplug the machine and lift the needle bar lever. Be sure to use cotton gloves to handle the needle as to not damage it. Now, turn the balance wheel to the right and lift the needle bar to the top.

At this point, you can align the small slot at the base of the needle with the slender needle clamp screw and slot it in place. Tighten the screw until it starts to become difficult to turn, ensuring it is firmly in place. Now, slowly lower the needle bar lever until it is in its original position.

If the needle insertion has been successful, the needle bar lever should be locked down and the needle should be set properly. To ensure it’s in the right spot, a small screw on the side of the machine should be adjusted so that the needle is in line with the centre of the cloth plate. You might want to double-check the needle’s alignment with a ruler to make sure it is set up correctly. Now, it is time to plug in the machine and switch it on.

The best way to avoid any potential problems and ensure that the needle stays in place is to use the right size needle for the fabric. Thicker and coarser fabrics such as denim require a stronger needle that won’t bend, while lighter materials like silk require a delicate needle. Additionally, the right kind of needle should also be used for the job at hand. For general stitching, a universal needle should suffice, while a needle with a sharp point should be used if working on stretchy fabrics.

Furthermore, if one is working on more intricate projects, it may be beneficial to use a specially-shaped needle such as a hemming or quilting needle. With these needles, it is essential to make sure that the bevel of the needle is facing the direction of the material or towards the back, as this will help ensure that the stitches are even and that the needle doesn’t break.

It is also important to remember to change the needle in the machine from time to time. This is especially necessary when working with fabrics or materials which require the use of a special needle for a longer period of time. After using the machine for a few hours, take out the needle and inspect it for wear and tear – if it’s worn or bent, it is time to change it.

Safety Considerations

Although it might appear relatively straight forward to insert a needle in a sewing machine, it is important to be mindful of safety while doing so. Always wear cotton gloves while handling the needle as well as when working with the machine to avoid any injuries.

Holding the needle firmly in one hand, insert the hole of the needle into the slot of the machine with your other hand, making sure that it is in the same direction as the presser foot. Never attempt to force the needle into the slot or pry the needle as this could damage the slot and risk injury.

Testing the Needle

Once the needle has been inserted, make sure to test the machine before beginning any sewing projects. Use some spare material to practice on and check the stitch quality of the machine to check if the needle has been set up correctly. The stitches should be even and well-defined and the tension of the fabric should also be balanced.

Inspect the needle for wobble or breakage – if either occurs when using the machine, there is a good chance that the needle was not inserted properly. If the machine shows signs of damage, it can result in further damage to the needle or machine, so it is essential to ensure that it is set up correctly to ensure long-term sewing success.

Threading the Needle

Once the needle has been inserted correctly, it is time to thread the needle.Most modern machines come with an automatic needle threader which helps to make the threading process simpler and quicker.

To make the process easier, thread the needle before you start the machine, provided that the machine is not running. Pass the thread through the eye of the needle, and then pull it back so that the loop is on the top of the needle. Grab the looped thread with a pair of tweezers or a hooked needle threader and pull it through the hole until it is tight.

Make sure to snip off any excess thread so that only the looped end remains. Leave yourself a few inches of thread hanging from the back, screw the needle and the long arm of the needle should face towards the back of the machine. Now, you’re ready to start stitching!

Storing a Needle

Once the project is completed and the machine has been used, it is important to store the needle and the machine properly for use in the future. Remove the needle from the machine using cotton gloves and store it in an airtight container to avoid any rusting or damage. This can help ensure that the needles last longer and that they are not accidentally damaged in the future.

It is also important to remember to clean the machine and its parts regularly, as this can help prevent dust and dirt from damaging the needle. Be sure to avoid cleaning the needle directly with cleaning solutions, as this can corrode it.

Maintenance of a Sewing Machine

In addition to changing the needle from time to time, it is also important to get the machine serviced by a professional for deep cleaning and maintenance. This ensures that the machine continues to run smoothly and efficiently, and that any hidden dirt and dust is removed.

This is important, as dust and dirt can affect the way the machine stitches and can even lead to damage in the needle, resulting in more costly repairs in the future.Finally, if any parts of the machine need replacing, be sure to get them fixed by a professional rather than attempting to fix the machine yourself.

Common Problems

When it comes to putting a needle in a sewing machine, one of the most common problems that occur is that the needle is inserted incorrectly. This can lead to the machine struggling to stitch correctly and can damage the needle as well as the machine itself.

It is important to familiarize yourself with the machine and the needle itself before attempting to insert the needle. If unsure, refer to the instruction manual for guidance and double-check that the needle has been inserted properly after setting it up.

In addition, it is also important to remember to use the right type and size of needle for the given project. Using a universal needle for all projects can result in the machine struggling to stitch and the needle potentially breaking. Keeping this in mind can help ensure a smoother sewing experience.

Conclusion

When it comes to putting a needle in a sewing machine, it is important to familiarize yourself with the needle and machine’s parts before attempting to insert it. Be sure to use cotton gloves to handle the needle and read the instruction manual for guidance. Always make sure that the needle is inserted correctly and tightened so that it stays in place.

Make sure to use the right type and size of the needle for the given project, and remember to change the needle from time to time.It is also essential to maintain the machine regularly and get it serviced by a professional to ensure longevity. Following these steps can help ensure that the machine runs smoothly and your projects are completed with ease.