Understand Your Sewing Machine

One of the most important steps to ensuring that your presser foot is placed securely on your sewing machine is understanding the features and components that your machine consists of. Before attempting the presser foot replacement, familiarise yourself with the different parts. Flip open the face plate to reveal a bobbin case, thread take-up guide, needle plate, and upper and lower threading. Take the time to recognise where the presser foot lever and presser foot holder are located – as this will play an important role when securing the presser foot on the machine.

Check the Condition of the Presser Foot

It is important to assess the condition of the presser foot before returning it to the machine, as any damage to the presser foot may lead to incorrect sewing performance. Check the screws that attach the presser foot for looseness. If the presser foot is vinyl-coated and furry, ensure the fabric does not become caught in the presser foot when its being attached to the machine. If applicable, make sure to replace the screw of the presser foot with a new one during the installation process.

Test Presser Foot Holder and Lever

In order to place the presser foot back on the sewing machine, the presser foot holder and lever need to be tested to ensure that they are properly adjusted and working correctly. Carefully look over the presser foot holder and lever, while they’re still attached to the machine, to make sure that they are in good working order. Once you’ve confirmed the presser foot holder and lever are working correctly, it’s time to return the presser foot to the machine.

Setting the Presser Foot

To setup the presser foot, begin by slidethe presser foot onto the presser foot holder. Make sure that the presser foot holder is still in the lowered position and then gently press the presser foot onto the holder. Once the presser foot is secured, raise the presser foot holder lever towards the rear of the machine. This will cause the presser foot to lock into place at the top of the presser foot holder. After securement, your presser foot is ready for use.

Adjust Height for Specific Applications

Depending on the sewing work being done, the presser foot height may need to be adjusted. If you’re inserting fabric or performing other detailed work, it may benefit to raise the presser foot. Raising the presser foot provides extra clearance at the needle plate, enabling fabric edges and seams to sit near the needle plate with ease. To adjust the presser foot height, simply lower the presser foot lever and move the presser foot to the desired height – then raise the presser foot again.

Practice Makes Perfect

The entire process of attaching the presser foot to a sewing machine should not take more than a few minutes. However, practice makes perfect and with each consecutive attempt you will be more familiar with the steps required to secure the presser foot correctly. The better you understand the components and how they fit together, the easier reinstalling the presser foot will be – resulting in a secure presser foot for successful sewing.

Secure Presser Foot for Maximum Durability and Performance

Once you’re sure that the presser foot is correctly reinstalled, take the time to double check its placement. Walk around the sewing machine’s exterior to make sure that nothing is obstructing the presser foot holder and that it’s still in the raised position. After a few simple steps, you will now have a secured presser foot holder in perfect condition, ready for use and providing optimum performance.

Clean and Oil the Sewing Machine Components

In order to ensure that the presser foot holder maintains optimum durability for a longer period of time, cleaning the sewing machine is an essential task. Firstly, start the cleaning process by removing all of the fabric lint that has accumulated. An upholstery brush, along with a gentle sweeping motion should suffice. Once the lint has been removed from the machine, use an oil dropper and oil the necessary mechanisms – while avoiding unsuitable areas such as contact points and motor areas.

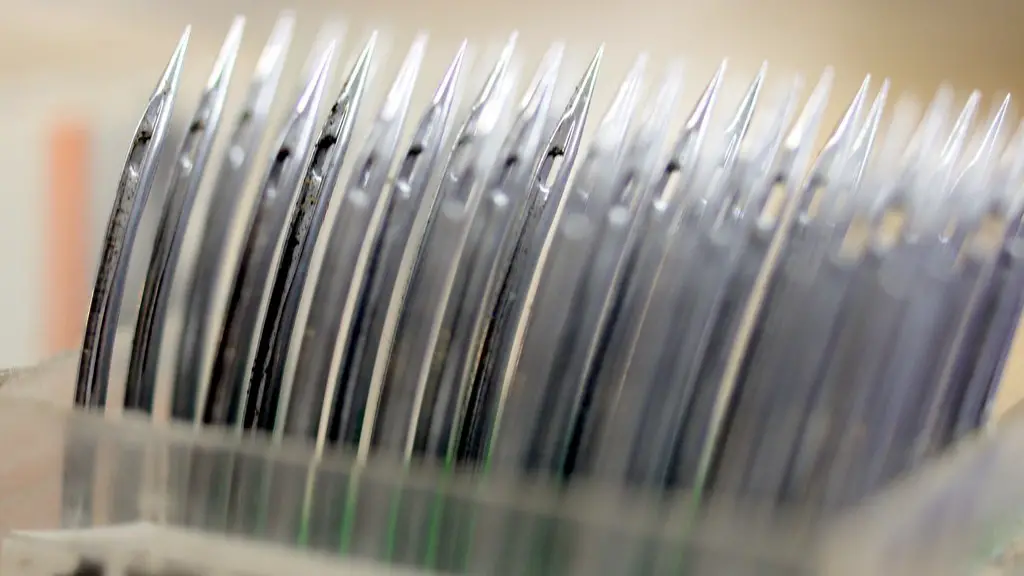

Keep a Supply of Needles

When using a sewing machine, it is important to always use the correct needle size and shape. Keeping a supply of various needles will greatly benefit your sewing journey – as it will enable you to use the correct needle with the right materials. Additionally, it is actively recommended to replace needles after 8 hours of sewing – or when you notice a decrease in performance.

Using the Right Thread

Thread can make a substantial difference when applied to a variety of fabric. Fibers such as nylon, polyester and cotton come in medium, lightweight and heavyweight covers for a range of sewing needs. Keep in mind that thinner fabric requires a lighter thread type and heavier fabric requires a heavy duty thread. Consider reading the instruction manual of your sewing machine to correctly identify the thread that is suitable for use.

Troubleshooting Your Sewing Machine Performance

Sewing machines can be quite a delicate process – especially when dealing with serious projects. If you’re experiencing a strange noise that seems to be coming from the needle plate, there are a few things that you should investigate. Firstly, check the presser foot and confirm that it’s adjusted correctly to the holder. Additionally, check if the presser foot has become loose and if it needs to be replaced with a new screw. Secondly, check the bobbin case and the needle plate – to see if they’re damaged and if they can be replaced with brand-new parts.

Performing Lock Stitch Adjustments

Lock stitch adjustments can be used to help stabilise lock stitches when the bobbin case runs out. If the bobbin case runs out, the thread position in the lower threading area may become adjustable. To adjust this, turn the tension adjuster on the bobbin case slightly counterclockwise. This leaves more slack in the tension of the lower thread, enabling an easier transition when stitch locking.

Using Needle Insertion Tools

Needle insertion tools offer a considerable amount of assistance when setting up their sewing machine for specific projects. The needle insertion tool may be used to quickly and accurately thread the needle for sewing. To use the tool, start by inserting the needle into the tool and then feed the thread into the tool. To secure the thread in place, twist the thread around the peg in the tool, which is located in the back of the tool.

Gripping the Thread with a Parts Tray

Using a parts tray is a creative way to grip the thread and sew with the thread in both directions. A parts tray is a special type of tray that can hold various small parts and components. To use the tray, start by threading the thread around the small pins of the tray. Then, grab the thread between the pins and pull away, enabling the thread to be grouped into small bundles. When you are ready to sew, use the group of threads in each bundle to provide a stable, firm grip on the fabric.