How to Put Thread on a Sewing Machine

Putting threadthrough a sewing machine is a fundamental skill for any sewer. Without the thread correctly installed and tensioned, it will be difficult to create a proper stitch. There are several steps that need to be taken to ensure the thread is put on correctly. The following guide will provide an overview of the process.

The first step to putting thread on a sewing machine is to choose the correct thread for the job. There are a variety of threads that can be used for sewing, and the type that is chosen should be based on the material being sewn as well as the desired effect. Cotton thread is best for lightweight fabrics, while heavier fabrics may require polyester or even nylon thread. It is also important to consider the size of the thread. The thread should be the same weight or a heavier weight than the fabric being used.

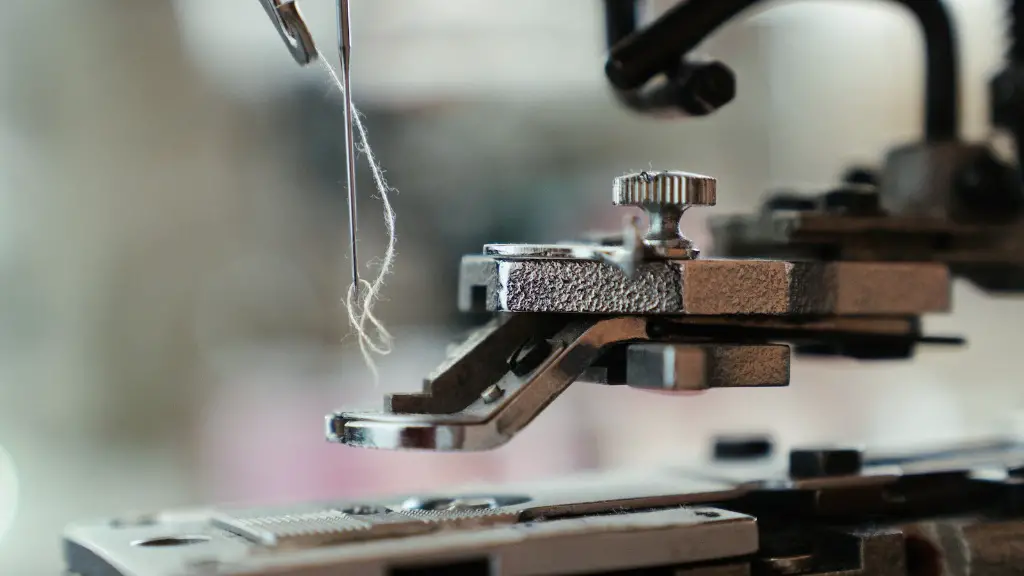

Once the right thread has been selected the next step is to thread the spool through the thread guides and tension discs, depending on the model of the machine. Most sewing machines will have several steps to complete this, with some having more than others. Once the thread is threaded through these components the correct tension should be established. To do this, the tension knob will need to be adjusted until the desired level of tension is achieved. Too little tension will result in a weak stitch, while too much tension could break the thread.

Once the thread is tensioned correctly the next step is to pull it through the needle. Most machines will have a needle threader available to make this step easier. If the thread is not correctly threaded through the needle the stitch will likely be weak, and the thread could break. The thread should always be on the left side of the needle and the needle should be lowered before threading it.

The final step is to thread the bobbin. This varies depending on the type of sewing machine. For some machines, the bobbin will need to be inserted and then threaded through the machine. For others, it will need to be put in an area of the machine, such as a bobbin case, and then threaded through as normal. Once the bobbin is thread it can be inserted into the machine.

Once the thread has been correctly put on the sewing machine, it is important to check the stitch quality before starting to sew. A good quality stitch should be even and consistent, with no skipped stitches. if the stitch is poor, then the tension will likely need to be adjusted. With a few simple steps, the right thread on a sewing machine can ensure a successful project.

Addressing Common Issues

If thread is breaking while sewing, it might be an issue with the tension. If the tension is too tight the thread could be breaking, but if it is too loose the stitches may be weak. Adjusting the tension to the correct level can fix this issue. In some cases, this could be caused by a dull needle, so replacing it with a sharp one can also be helpful.

Skipping stitches can be a common issue with sewing machines, and in many cases this is caused by the tension being incorrect. This can also be caused by the needle being the wrong size for the thread being used. Check to make sure the needle is both the correct size and type for the job.

A common issue with sewing machines is thread looping. This is when the thread from the bobbin appears on the upper side of the fabric. When this happens, it usually means that the needle is not fully inserted or that the needle is bent. Inspect the needle and make sure it is correctly installed and straight.

When having trouble with a sewing machine, the first step should be inspecting the upper and lower thread to make sure they are correctly tensioned and installed. If the problem still persists then it may be an issue with the machine itself, in which case it should be serviced or checked.

Why Is Threading Important?

Threading is an important part of sewing machines, as it ensures that the thread will stitch properly and securely. Without the thread being correctly threaded and tensioned, it will be difficult to produce a good stitch. With the right thread on the sewing machine, a successful project can be made with ease.

Threading is also important for ensuring that the machine can run smoothly and without any issues. If the thread is not correctly tensioned and threaded, then the machine may not function properly. Frequent machine breakages and issues can be avoided if the thread is correctly tensioned and threaded.

In addition, correct threading helps to prevent thread breakages when sewing. If the thread is not correctly threaded and tensioned the thread could snap while sewing. This is an issue that could lead to wasted time, fabric, and thread, so it is important to make sure that the thread is correctly threaded and tensioned on a sewing machine.

Finally, threading a sewing machine is important for maintaining the fabric when sewing. If the thread is too tight, it can cause problems like puckering, which could damage the fabric. Correct and even tension is important for maintaining the shape and integrity of the fabric when sewing.

Tools and Materials Needed

The tools and materials needed for putting thread on a sewing machine depend on the type of machine and thread being used. The most basic items are a spool of thread, thread scissors, and a needle threader. For certain machines, additional components such as thread guides and tension discs may also be required.

A needle threader is a tool which can be very helpful when threading thread through the needle. It is a small, thin metal tool that quickly and reliably threads the needle with thread. Needle threaders are available in most fabric stores, and they can make threading the needle much faster and easier.

In addition, thread scissors can make cutting the thread much quicker and easier. Thread scissors are designed to be sharp and precise, allowing them to quickly and accurately cut thread. They are usually much smaller than regular scissors, and can be used for cutting both thick and thin threads.

Finally, thread guides and tension discs may also be required for some types of sewing machines. These components are designed to help keep the thread taut as it passes through the machine, allowing for even tension and stronger stitches.

Tips for Threading a Sewing Machine

There are a few tips that can help makesure that threading a sewing machine is successful. The first tip is to make sure that the thread is the right size and material for the job. If a heavier thread is used than the material being sewn it could damage it, while a lighter thread could cause issues with the stitch.

The tension should also always be checked before sewing, as this can affect the quality of the stitches. A slightly looser or tighter tension could cause the stitch to be weaker or even breaking. It is important to ensure that the tension is correct for the fabric and thread being used.

When threading the needle, it is important to make sure that the thread is on the left side of the needle and to lower the needle before threading. This ensures that the thread is correctly inserted and will make sure the thread is tensioned correctly.

Finally, it is important to inspect the stitch quality before beginning to sew. This will make sure that the thread is correctly tensioned and will prevent any issues that could arise. This ensures that the project can be completed successfully.

Cleaning and Maintaining the Sewing Machine

Cleaning and maintaining a sewing machine properly is a critical part of ensuring that it runs well and produces a high-quality stitch. It is important to regularly clean the machine and make sure it is in good working order. It is also important to lubricate the machine regularly.

Cleaning a sewing machine should be done with a cloth and a mild soap and water solution. Do not use any harsh chemicals, as these could potentially damage the machine. Once the machine has been cleaned, it should be checked for any issues or damage.

It is also important to lubricate the machine on a regular basis. Sewing machine oil can be used to lubricate the moving parts of a machine, and this should be done weekly or as needed. This helps ensure that the machine can run smoothly and can avoid any technical issues.

Finally, it is important to inspect the machine regularly. This can help to identify any issues or problems early, and can help prevent any potential breakdowns or damage to the machine. It is important to make sure that the tension is correct, and to make sure the needle is both the correct size and type for the fabric being used.